The definitive answer is that there is no single, universal schedule for calibrating a zirconia sintering furnace. The correct frequency is determined by your specific furnace model, its usage level, and the manufacturer's explicit recommendations. Adhering to the guidelines in your user manual is the essential starting point for any calibration protocol.

Your core challenge isn't finding a magic number for calibration frequency. It's about shifting your mindset from viewing calibration as a periodic chore to treating it as a continuous quality control process that directly safeguards the strength, fit, and aesthetics of every zirconia restoration you produce.

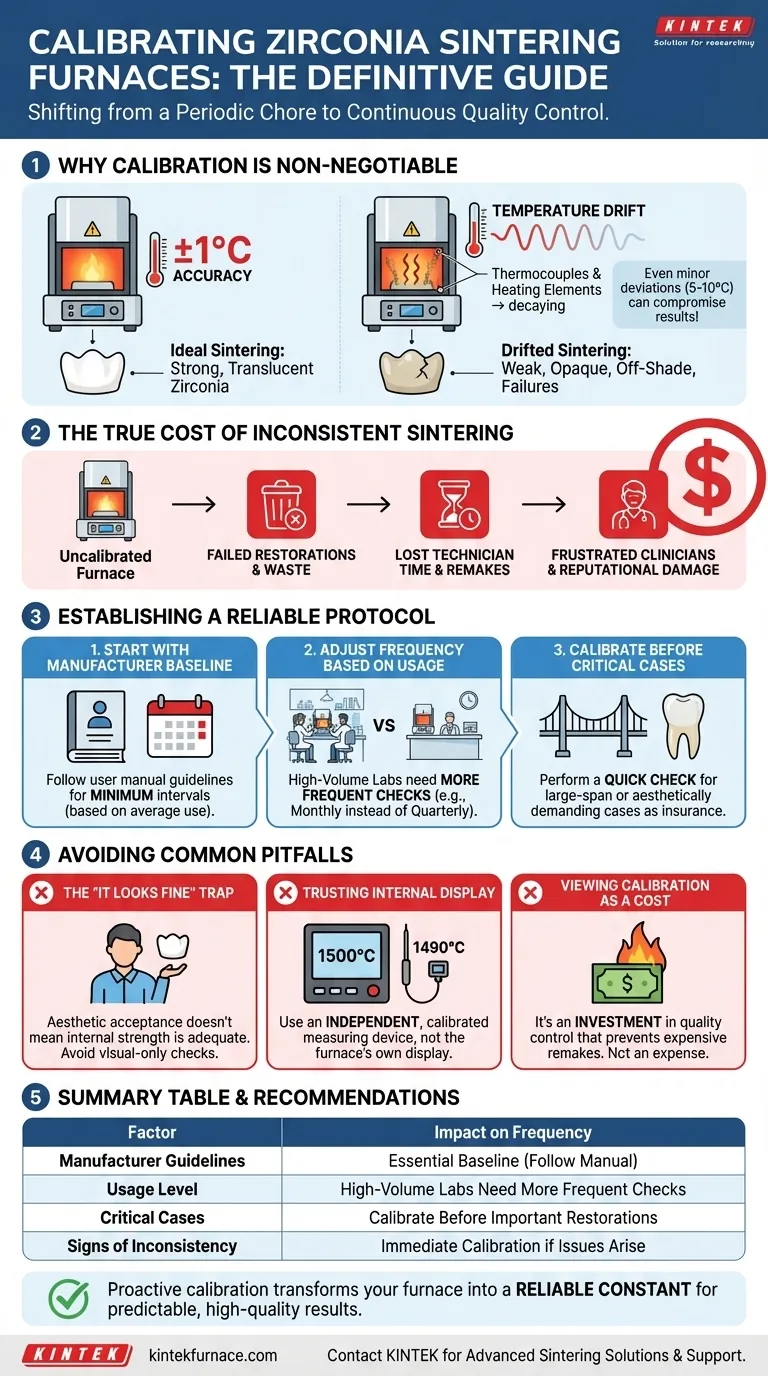

Why Calibration is Non-Negotiable for Zirconia

The success of a zirconia restoration is critically dependent on achieving a precise temperature profile during the sintering cycle. Even minor deviations can lead to catastrophic failures that are not always immediately visible.

The Critical Role of Temperature Accuracy

Modern sintering furnaces often boast a temperature accuracy of ±1℃. This isn't a marketing gimmick; it's a technical necessity.

Zirconia undergoes phase transformations at specific temperatures. If the furnace runs too cool, the material won't achieve full density, resulting in a weak and opaque restoration. If it runs too hot, it can lead to grain growth, which reduces strength and can affect the final shade.

Understanding "Temperature Drift"

A furnace does not remain stable indefinitely. The components responsible for measuring and generating heat—thermocouples and heating elements—degrade over time.

This gradual decline in accuracy is known as "temperature drift." A furnace that was perfectly accurate last month may be off by 5-10°C this month, which is more than enough to compromise your results.

The True Cost of Inconsistent Sintering

An uncalibrated furnace leads directly to wasted resources and reputational damage.

The costs manifest as failed restorations, material waste, lost technician time for remakes, and frustrated clinicians who lose confidence in your lab's consistency.

Establishing a Reliable Calibration Protocol

Instead of searching for a one-size-fits-all answer, you must build a protocol tailored to your lab's specific conditions. This involves a combination of manufacturer guidance and real-world observation.

Start with the Manufacturer's Baseline

Your furnace's user manual is your primary source of truth. The manufacturer has tested the equipment extensively and provides a recommended calibration interval based on average use. Follow this guideline as your absolute minimum.

Adjust Frequency Based on Usage

A lab running its furnace for multiple cycles every day will experience faster component degradation than a lab running one cycle every other day.

If you are a high-volume lab, you must shorten the interval between calibrations. For example, if the manual suggests quarterly calibration, you may need to move to a monthly or even bi-weekly schedule to ensure consistency.

When to Calibrate Before a Single Use

For highly critical or complex cases, such as large-span bridges or aesthetically demanding anterior restorations, performing a quick calibration check before the cycle is a prudent form of insurance. This ensures the most important cases are sintered under ideal conditions.

Understanding the Common Pitfalls

Many well-intentioned labs fall into traps that undermine their quality control. Recognizing these pitfalls is the first step to avoiding them.

The "It Looks Fine" Trap

Relying on a simple visual check of a sintered crown is dangerous. A restoration can look acceptable aesthetically while having internal stresses or compromised flexural strength, making it prone to premature failure in the patient's mouth.

Trusting the Furnace's Internal Display

The purpose of calibration is to verify that the temperature reported on the furnace's screen matches the actual temperature inside the chamber.

You cannot use the furnace's own display to check its accuracy. Calibration requires an independent, properly calibrated measuring device to get an objective reading.

Viewing Calibration as a Cost

The fee for a qualified technician or the time it takes to perform a calibration is minimal compared to the cost of a single remake.

Framing calibration as a necessary investment in quality control, rather than an operational expense, is crucial. It prevents far greater costs down the line.

Making the Right Choice for Your Lab

Use these guidelines to build a calibration strategy that ensures predictable, high-quality results for your specific operational needs.

- If you are a new lab or have a new furnace: Strictly follow the manufacturer's manual to establish a performance baseline and maintain your warranty.

- If you are a high-volume production lab: Calibrate more frequently than the minimum recommendation, adjusting your schedule based on the stability and consistency of your results.

- If your results suddenly seem inconsistent (chipping, poor fit, or off-shades): Stop and calibrate immediately. An uncalibrated furnace is the most probable cause.

Proactive calibration transforms your sintering furnace from a potential variable into a reliable constant, ensuring predictable, high-quality results every time.

Summary Table:

| Factor | Impact on Calibration Frequency |

|---|---|

| Manufacturer Guidelines | Essential baseline; follow user manual for minimum intervals |

| Usage Level | High-volume labs need more frequent checks (e.g., monthly vs. quarterly) |

| Critical Cases | Calibrate before important restorations like bridges or anterior teeth |

| Signs of Inconsistency | Immediate calibration if issues like chipping or poor fit arise |

Ensure your zirconia sintering furnace delivers consistent, high-quality results with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide dental labs with reliable high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique needs. Contact us today to optimize your calibration strategy and enhance your lab's performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations