In essence, vacuum heat treatment ensures high-quality results by creating an ultra-pure, controlled environment. By removing air and other reactive gases from a sealed chamber, the process eliminates the primary causes of defects like oxidation and contamination, allowing for precise control over the heating and cooling cycles. This guarantees the final material properties are consistent, predictable, and superior.

The true value of vacuum heat treatment is not just about heat; it's about control. By removing the variable of atmospheric reaction, you eliminate the root causes of material defects, ensuring the component's surface integrity and internal structure are exactly what you designed them to be.

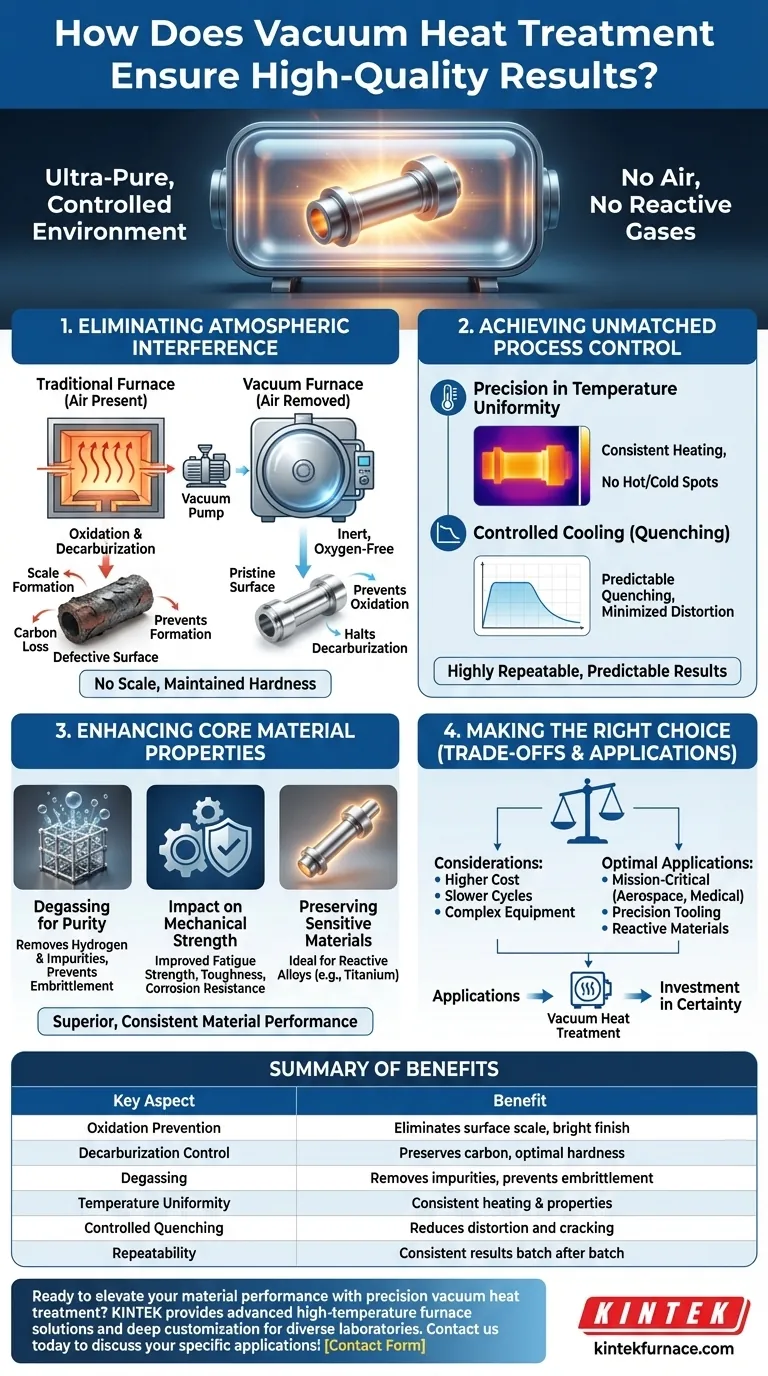

The Foundational Principle: Eliminating Atmospheric Interference

Heat treatment relies on precise thermal cycles to alter a material's microstructure. However, when performed in the presence of air, cái hot metal surface readily reacts with oxygen, nitrogen, and water vapor, leading to unpredictable and undesirable outcomes.

What is a Vacuum Environment?

A vacuum furnace uses a system of pumps to remove the air from a sealed chamber before heating begins. This creates an environment where reactive gases are virtually nonexistent.

This oxygen-free condition is the cornerstone of the process, preventing a host of chemical reactions that would otherwise degrade the workpiece.

Preventing Surface Oxidation

In traditional furnaces, oxygen reacts with the hot metal to form a dark, brittle oxide layer, or "scale." This scale degrades the surface finish, reduces dimensional accuracy, and must be removed through costly secondary operations.

Vacuum treatment completely prevents oxidation. The part emerges from the furnace with a clean, bright, and metallic luster, maintaining its precise dimensions and surface quality.

Halting Decarburization

For carbon steels, exposure to oxygen at high temperatures can pull carbon atoms from the surface, a defect known as decarburization. This creates a soft outer layer that compromises hardness and wear resistance.

The inert vacuum environment stops this reaction, ensuring the carbon content—and therefore the hardness—of the material's surface remains exactly as specified.

Achieving Unmatched Process Control and Consistency

Beyond preventing contamination, the vacuum environment enables a level of control that atmospheric furnaces cannot match. This leads to highly repeatable and predictable results.

Precision in Temperature Uniformity

The absence of air allows for heating primarily through radiation, which can be controlled with extreme precision. This ensures uniform temperature distribution across the entire workpiece, even for complex geometries.

Consistent heating eliminates hot spots and cold spots, guaranteeing that the entire part undergoes the intended metallurgical transformation.

Controlled Cooling (Quenching)

Quenching, the rapid cooling descuentos, is critical for achieving hardness. Vacuum furnaces can use high-pressure gas quenching (e.g., with nitrogen or argon) or integrate with sealed oil-quenching tanks.

This controlled environment makes the cooling process highly predictable, minimizing the thermal shock and distortion that can lead to part cracking or dimensional instability.

The Benefit of Repeatability

By eliminating the variables of atmospheric composition and uncontrolled convection, vacuum heat treatment becomes a highly stable process. Each batch is treated under nearly identical conditions, ensuring consistent quality from the first part to the last.

Enhancing Core Material Properties

The benefits of vacuum treatment extend deep into the material itself, improving its fundamental mechanical properties.

Degassing for Improved Purity

The vacuum actively pulls trapped gases, such as hydrogen and dissolved impurities, out of the metal's internal structure. This "degassing" effect significantly improves the material's purity.

Removing hydrogen is especially critical, as it prevents hydrogen embrittlement, a catastrophic failure mechanism that can cause high-strength steels to crack under load.

The Impact on Mechanical Strength

A clean, uncontaminated surface free of micro-cracks and oxide inclusions dramatically improves a part's performance. Materials treated in a vacuum often exhibit enhanced fatigue strength, toughness, and corrosion resistance.

Preserving Sensitive Materials

Metals like titanium and other refractory alloys are extremely reactive at high temperatures. Vacuum treatment is essential to prevent them from becoming brittle by absorbing oxygen or nitrogen from the air.

Understanding the Trade-offs

While its benefits are clear, vacuum heat treatment is not a universal solution. Understanding its limitations is key to making an informed decision.

The Cost Factor

Vacuum furnaces represent a significant capital investment. Their operational costs, including energy consumption and maintenance of the vacuum systems, are also higher than those of conventional atmospheric furnaces.

Slower Cycle Times

The process of pumping down the chamber to the required vacuum level adds time to each cycle. For high-volume, low-spec parts, this can make the process less economical than faster, continuous atmospheric treatments.

Equipment Complexity

These systems are more complex than their atmospheric counterparts, requiring specialized knowledge for operation and maintenance. The size of the effective working area within the furnace can also be a limiting factor.

Making the Right Choice for Your Application

Ultimately, the decision to use vacuum heat treatment depends on the specific requirements of your component and its intended application.

- If your primary focus is mission-critical performance (aerospace, medical, defense): Vacuum treatment is often non-negotiable for its ability to deliver parts with a pristine surface and superior, repeatable mechanical properties.

- If your primary focus is high-precision tooling, dies, or gears: The process is essential for achieving maximum surface hardness and wear resistance without the distortion or decarburization common in other methods.

- If your primary focus is reactive or sensitive materials (e.g., titanium): Vacuum treatment is the only way to process these materials without causing surface embrittlement and compromising their integrity.

- If your primary focus is cost-sensitive, high-volume production of non-critical parts: Traditional atmospheric treatments may provide a more economical solution if a bright finish and perfect surface integrity are not required.

Choosing vacuum heat treatment is an investment in certainty, guaranteeing your material performs exactly as intended.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Oxidation Prevention | Eliminates surface scale, maintains dimensional accuracy and bright finish |

| Decarburization Control | Preserves carbon content for optimal hardness and wear resistance |

| Degassing | Removes hydrogen and impurities to prevent embrittlement and improve purity |

| Temperature Uniformity | Ensures consistent heating for uniform material properties |

| Controlled Quenching | Reduces distortion and cracking with predictable cooling cycles |

| Repeatability | Delivers consistent results batch after batch for reliable performance |

Ready to elevate your material performance with precision vacuum heat treatment? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, medical, tooling, or handling reactive materials, we can help you achieve superior results with consistent quality and enhanced mechanical properties. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today