In short, a vacuum furnace refines metal by creating an environment where purity is not just protected, but actively created. By removing atmospheric gases, the vacuum prevents oxidation and contamination that would otherwise occur at high temperatures. More importantly, this low-pressure environment acts like a magnet, pulling dissolved gases and volatile impurities out from deep within the metal itself.

The core function of a vacuum furnace is not merely to shield the metal from the outside air. Its true value lies in its ability to actively purify the material from within, leading to a level of chemical purity and structural integrity that is unattainable in a standard atmosphere.

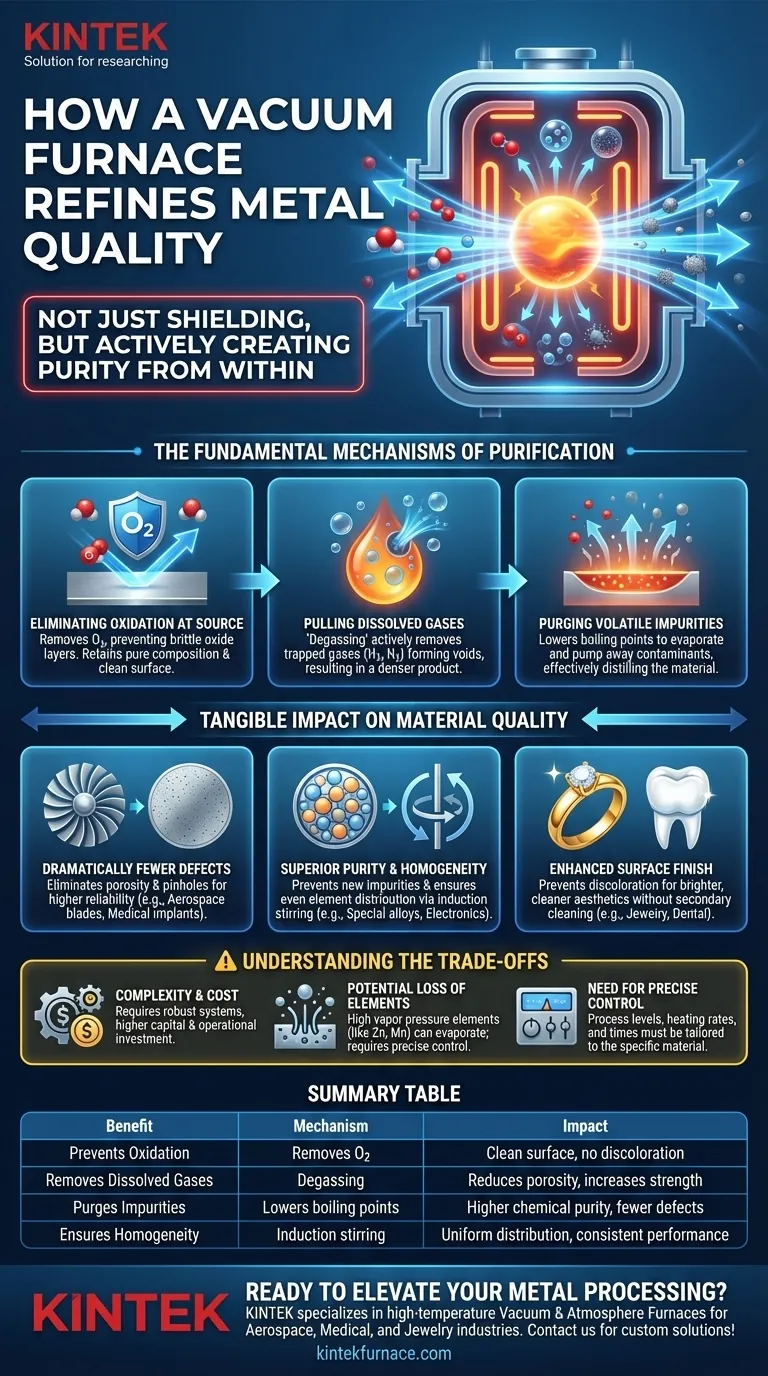

The Fundamental Mechanisms of Vacuum Purification

Processing metals at high temperatures makes them highly reactive. The vacuum environment systematically addresses the primary sources of contamination and structural defects that arise from this reactivity.

Eliminating Oxidation at the Source

Any oxygen present during heating will instantly react with a hot metal surface, forming oxides. These brittle, undesirable layers compromise the material's integrity and finish.

A vacuum furnace removes virtually all atmospheric gases, including oxygen, preventing oxidation before it can begin. This ensures the metal retains its pure, intended composition and a clean surface.

Pulling Dissolved Gases from Within the Metal

Molten metals can dissolve significant amounts of atmospheric gases like hydrogen, nitrogen, and oxygen. As the metal cools and solidifies, the solubility of these gases drops sharply.

The trapped gases attempt to escape, forming microscopic voids, pinholes, and porosity. These defects act as stress concentrators, drastically reducing the material's strength and fatigue life. A vacuum environment actively pulls these dissolved gases out of the molten metal, a process known as degassing, resulting in a much denser and more solid final product.

Purging Volatile Impurities

Many undesirable tramp elements and impurities have a higher vapor pressure (they evaporate more easily) than the base metal.

Under vacuum, the boiling point of all materials is lowered. This allows volatile contaminants to boil off and be pumped away at temperatures where the desired metal remains stable, effectively distilling the material to a higher state of purity.

The Tangible Impact on Material Quality

This multi-pronged purification process translates directly into superior material properties that are critical for high-performance applications.

Dramatically Fewer Internal Defects

By preventing oxidation and removing dissolved gases, vacuum processing significantly reduces or eliminates common defects like porosity, oxide inclusions, and pinholes.

This results in materials with higher reliability and predictable mechanical behavior, which is non-negotiable for critical components like aerospace turbine blades and medical implants.

Superior Chemical Purity and Homogeneity

The vacuum environment ensures no new impurities are introduced and helps remove existing ones. In alloy production, this clean slate allows for precise control over the final composition.

Furthermore, some vacuum furnaces use induction heating, which creates an electromagnetic stirring effect. This ensures all alloying elements are distributed evenly, preventing segregation and guaranteeing consistent performance throughout the material.

Enhanced Surface Finish and Aesthetics

For applications like jewelry and dental ceramics, surface quality is paramount. A vacuum furnace prevents the surface discoloration and irregularities caused by oxidation.

This results in a brighter, cleaner, and more aesthetically pleasing final product without the need for aggressive secondary cleaning or polishing.

Understanding the Trade-offs

While powerful, vacuum processing is not a universal solution. A clear understanding of its limitations is essential for making an informed decision.

Process Complexity and Cost

Vacuum furnaces are inherently more complex and expensive to build, operate, and maintain than standard atmospheric furnaces. They require robust vacuum pumps, seals, and control systems, which adds to both capital and operational costs.

Potential Loss of High-Vapor-Pressure Elements

The same principle that removes volatile impurities can also work against you. If an alloy contains essential elements with a high vapor pressure (like zinc or manganese), they can be unintentionally boiled off during the vacuum process. This requires careful control of temperature and vacuum levels to manage the evaporation rates of different elements.

The Need for Precise Control

Effective vacuum processing is not as simple as turning on a pump. The specific level of vacuum, the heating rate, and the holding time must all be precisely tailored to the specific metal, alloy, and desired outcome. An improper process can be ineffective or even detrimental to the material.

Making the Right Choice for Your Application

Selecting the right thermal processing environment depends entirely on your end goal.

- If your primary focus is maximum structural integrity (e.g., aerospace, power generation): Vacuum processing is essential to remove the dissolved gases that cause porosity and embrittlement.

- If your primary focus is creating ultra-high-purity metals or special alloys (e.g., electronics, research): A vacuum induction furnace offers the dual benefit of a pure environment and electromagnetic stirring for ultimate homogeneity.

- If your primary focus is a perfect surface finish and aesthetics (e.g., jewelry, dental): The oxygen-free vacuum environment is the most reliable way to prevent the oxidation that causes surface defects and discoloration.

Ultimately, mastering metal quality requires controlling its environment, and a vacuum provides the highest degree of control possible.

Summary Table:

| Benefit | Mechanism | Impact on Metal Quality |

|---|---|---|

| Prevents Oxidation | Removes atmospheric oxygen | Clean surface, no discoloration |

| Removes Dissolved Gases | Degassing under vacuum | Reduces porosity, increases strength |

| Purges Impurities | Lowers boiling points of volatiles | Higher chemical purity, fewer defects |

| Ensures Homogeneity | Electromagnetic stirring in some models | Uniform alloy distribution, consistent performance |

Ready to elevate your metal processing with advanced vacuum furnace solutions? KINTEK specializes in high-temperature furnaces, including Vacuum & Atmosphere Furnaces, tailored for industries like aerospace, medical, and jewelry. Our deep customization capabilities ensure your unique experimental needs are met with precision. Contact us today to discuss how we can enhance your material quality and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density