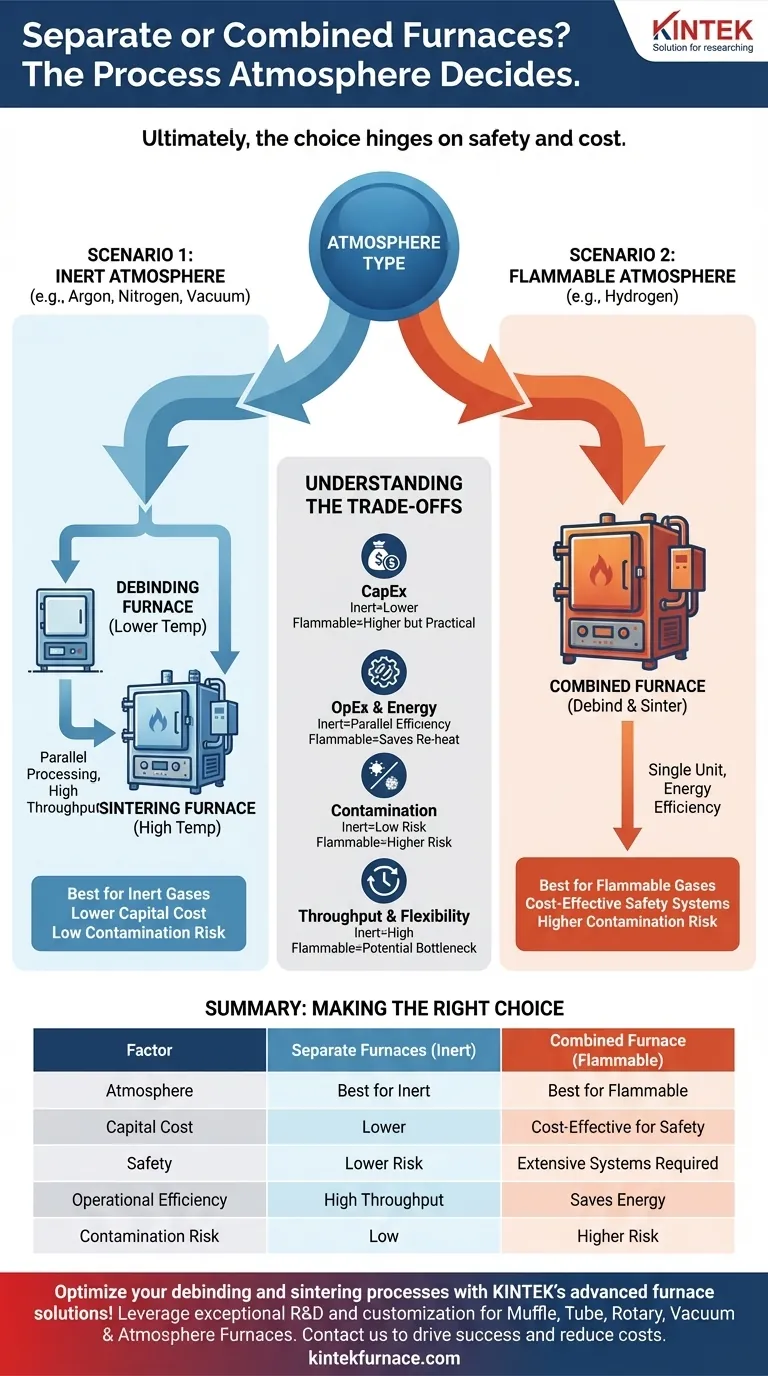

Ultimately, the choice hinges on safety and cost. The type of process atmosphere required—specifically whether it is inert or flammable—is the primary factor that dictates the economic and practical viability of using separate furnaces versus a combined unit for debinding and sintering. For inert atmospheres like argon, separate furnaces are often more cost-effective, whereas for flammable atmospheres like hydrogen, the extensive safety requirements make a single, combined furnace the more logical choice.

Your decision is a direct trade-off between initial capital cost and operational complexity. The high cost of safety systems required for flammable gases often erases the financial benefit of a simpler, separate debinding furnace, pushing the advantage toward a single, multi-process unit.

The Core Factor: Atmosphere and Equipment Cost

The process atmosphere directly impacts the design, safety features, and therefore the cost of the furnace equipment. This is the most significant variable in the decision-making process.

Scenario 1: Inert Atmospheres (Vacuum, Argon, Nitrogen)

When your process uses an inert atmosphere, the equipment requirements for debinding and sintering are vastly different. A debinding furnace is a relatively low-cost unit designed for lower temperatures.

In this scenario, a two-furnace setup is often the most economical choice. You can invest in a simple, specialized debinding furnace and a separate, more expensive high-temperature sintering furnace, optimizing your capital expenditure.

Scenario 2: Flammable Atmospheres (Hydrogen)

Using hydrogen fundamentally changes the cost calculation. Any furnace running a flammable gas requires extensive and expensive safety measures.

These include certified components, gas monitoring systems, emergency ventilation, and robust safety interlocks. These requirements elevate the cost of a "simple" debinding furnace to a level that approaches that of a full sintering furnace.

Because the cost difference is minimal, it becomes far more practical and cost-effective to perform both debinding and sintering in a single, combined furnace that is already built to handle hydrogen safely.

Understanding the Trade-offs

While atmosphere is the primary driver, a complete analysis requires weighing capital costs against operational factors like efficiency, contamination risk, and production throughput.

Capital Expenditure (CapEx)

As established, the initial investment is the clearest distinction. For inert gas processes, two separate, specialized units can often be cheaper than one highly complex combined unit.

For flammable gas processes, the high cost of safety systems on two separate units makes a single, combined furnace the more financially sound investment.

Operational Efficiency and Energy

A combined furnace saves energy by eliminating the cool-down and re-heat cycle required when moving parts between two separate furnaces.

However, this is not an absolute rule. A metallic sintering furnace forced to run at a high partial pressure during its debinding cycle can be less efficient and consume more energy than two separate, optimized units.

Process Purity and Contamination

A significant advantage of a two-furnace system is the prevention of cross-contamination. The debinding process releases binder residues that can deposit on the furnace interior.

In a combined furnace, these residues can vaporize during the high-temperature sintering phase and contaminate the final parts, potentially compromising material properties. A separate debinding furnace isolates these contaminants completely.

Throughput and Flexibility

A two-furnace production line offers higher throughput and greater flexibility. Debinding and sintering can occur in parallel, meaning one batch can be sintering while the next is debinding.

A single furnace creates a bottleneck. The entire unit is occupied for the full duration of both cycles, limiting your overall production capacity.

Making the Right Choice for Your Process

Your optimal furnace configuration depends on which operational factor is most critical to your business goals.

- If your primary focus is minimizing initial cost with inert gases: A separate debinding and sintering furnace setup is your most economical path forward.

- If your primary focus is safety and simplicity with flammable gases: A single, combined furnace designed to handle hydrogen is the most practical and cost-effective solution.

- If your primary focus is maximum throughput and part purity: Two separate furnaces are superior, as they allow for parallel processing and eliminate the risk of cross-contamination.

By carefully weighing the cost of safety against your specific production needs, you can make a sound and strategic equipment investment.

Summary Table:

| Factor | Separate Furnaces | Combined Furnace |

|---|---|---|

| Atmosphere Type | Best for inert (e.g., argon) | Best for flammable (e.g., hydrogen) |

| Capital Cost | Lower for inert gases | Higher initial cost, but cost-effective for flammable gases |

| Safety | Lower risk with inert gases | Requires extensive safety systems for flammable gases |

| Operational Efficiency | Higher throughput with parallel processing | Saves energy by eliminating cool-down/re-heat cycles |

| Contamination Risk | Low, due to isolation of debinding residues | Higher risk of cross-contamination |

| Flexibility | High, allows independent process control | Lower, as furnace is occupied for full cycle |

Optimize your debinding and sintering processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you need separate units for inert atmospheres or combined systems for flammable gases to enhance safety, efficiency, and part purity. Contact us today to discuss how our solutions can drive your success and reduce operational costs!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What is the function of laboratory high-temperature box furnaces in T6 aluminum treatment? Key to Material Strength

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure