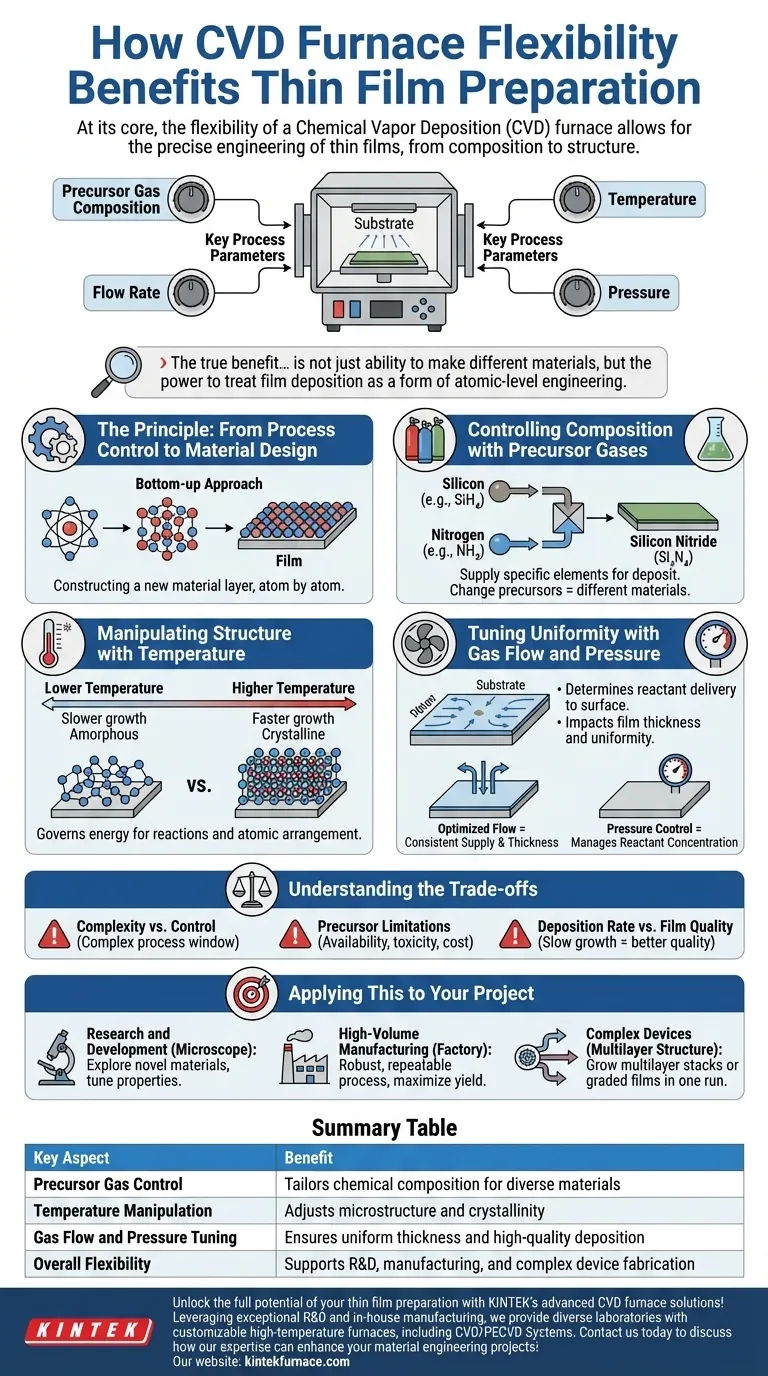

At its core, the flexibility of a Chemical Vapor Deposition (CVD) furnace is its most significant advantage, allowing for the precise engineering of thin films. This adaptability stems from the ability to independently control key process parameters—specifically the precursor gas composition, flow rate, temperature, and pressure—to dictate the final film's chemical makeup, atomic structure, and functional properties.

The true benefit of a CVD furnace's flexibility is not just the ability to make different materials, but the power to treat film deposition as a form of atomic-level engineering. It provides a toolkit to design and build a material from the ground up to meet a specific performance target.

The Principle: From Process Control to Material Design

The power of CVD lies in its "bottom-up" approach. You are not simply coating a surface; you are constructing a new material layer, atom by atom, by controlling the chemical reactions that occur on that surface.

Controlling Composition with Precursor Gases

The choice of precursor gases is the most direct control you have over the film's composition. By introducing different gases into the chamber, you supply the specific elements needed for the deposit.

For example, to grow silicon nitride (Si₃N₄), you would introduce gases containing silicon (like silane, SiH₄) and nitrogen (like ammonia, NH₃). Changing these precursors allows you to deposit entirely different materials.

Manipulating Structure with Temperature

Temperature is the primary lever for controlling the film's microstructure and crystallinity. It governs the energy available for chemical reactions and for atoms to arrange themselves on the substrate.

Higher temperatures typically increase reaction rates and provide atoms with more mobility, promoting the formation of a dense, crystalline structure. Lower temperatures may result in slower growth or an amorphous (non-crystalline) film.

Tuning Uniformity with Gas Flow and Pressure

The dynamics of gas flow and the overall system pressure determine how reactant molecules are delivered to the substrate surface. This directly impacts the film's thickness and uniformity.

Optimized gas flow ensures that all areas of the substrate receive a consistent supply of precursor, preventing variations in thickness. Pressure control helps manage the concentration of reactants and the mean free path of molecules, influencing the deposition rate and quality.

Understanding the Trade-offs

This high degree of control is powerful, but it comes with inherent complexities and limitations that must be managed.

Complexity vs. Control

The sheer number of interdependent variables (temperature, pressure, flow rates, gas ratios) creates a complex process window. Finding the optimal "recipe" for a specific film with desired properties can be a time-consuming and iterative process of experimentation.

Precursor Limitations

The CVD process is entirely dependent on the availability of suitable chemical precursors. These compounds must be volatile enough to be transported as a gas but reactive enough to decompose at the desired temperature. They can also be expensive, highly toxic, or pyrophoric, adding significant safety and cost considerations.

Deposition Rate vs. Film Quality

There is often a direct trade-off between the speed of deposition and the quality of the resulting film. Achieving highly uniform, crystalline, and defect-free films often requires slow, carefully controlled growth rates, which can impact manufacturing throughput.

Applying This to Your Project

Your approach to leveraging CVD's flexibility should be guided by your ultimate goal.

- If your primary focus is Research and Development: Use the wide parameter space to explore novel materials, tune properties systematically, and discover new structure-property relationships.

- If your primary focus is High-Volume Manufacturing: Concentrate on defining a robust, repeatable process recipe and locking down parameters to maximize yield and consistency.

- If your primary focus is creating Complex Devices: Leverage the ability to change gas composition and conditions mid-process to grow multilayer stacks or graded-composition films within a single run.

Ultimately, mastering a CVD furnace is about translating a desired material property into a specific set of process parameters.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Precursor Gas Control | Tailors chemical composition for diverse materials like silicon nitride |

| Temperature Manipulation | Adjusts microstructure and crystallinity for desired film properties |

| Gas Flow and Pressure Tuning | Ensures uniform thickness and high-quality deposition |

| Overall Flexibility | Supports R&D, manufacturing, and complex device fabrication |

Unlock the full potential of your thin film preparation with KINTEK's advanced CVD furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with customizable high-temperature furnaces, including CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether for research, high-volume production, or complex device creation. Contact us today to discuss how our expertise can enhance your material engineering projects!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes