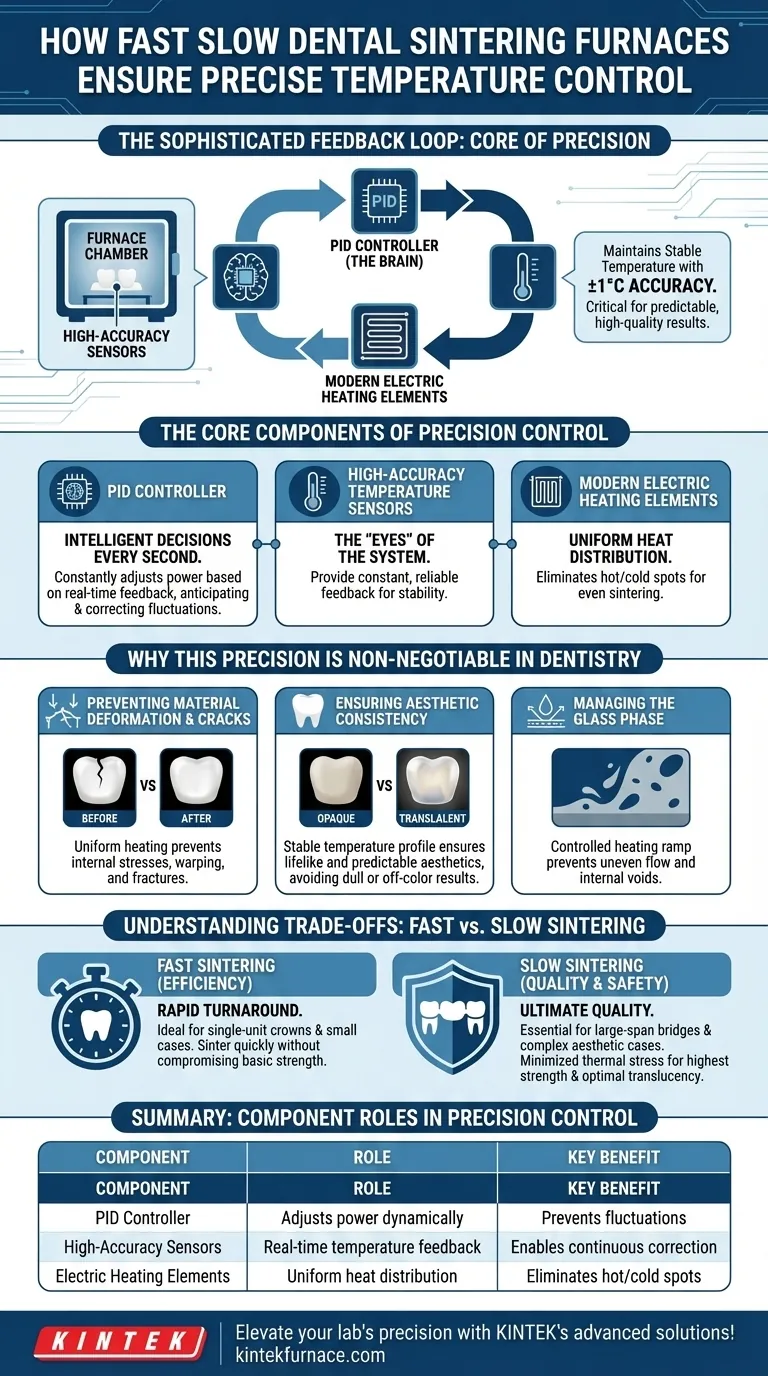

At its core, a Fast Slow Dental Sintering Furnace achieves precision through a sophisticated feedback loop. This system continuously measures the internal temperature with accurate sensors and uses an advanced PID (Proportional-Integral-Derivative) controller to dynamically adjust the power sent to the electric heating elements. This constant self-correction is what allows the furnace to maintain a stable temperature with an accuracy of ±1°C, which is critical for predictable and high-quality results.

Precise temperature control is not merely a feature; it is the fundamental mechanism that governs the structural integrity and aesthetic quality of the final dental restoration. Understanding how the furnace manages temperature fluctuations is key to trusting its output and mastering the sintering process.

The Core Components of Precision Control

A dental furnace operates as an integrated system. The precision comes not from a single part, but from the interaction between three critical components working in concert.

The PID Controller: The System's Brain

The heart of the temperature control system is the PID (Proportional-Integral-Derivative) controller. This is a small computer that makes intelligent decisions every second.

Think of it like a car's cruise control. It doesn't just turn the heat on or off. It constantly adjusts the power to the heating elements based on real-time feedback, anticipating and correcting for tiny temperature drops or spikes before they become significant.

High-Accuracy Temperature Sensors

The PID controller relies on data from high-accuracy temperature sensors placed strategically within the furnace chamber. These sensors are the "eyes" of the system.

They provide the constant, reliable feedback needed to maintain temperature stability. Without accurate sensors, even the most advanced controller would be working with flawed information, leading to inconsistent outcomes.

Modern Electric Heating Elements

Modern furnaces use high-temperature electric heating elements, a significant advancement over older combustion-based methods.

Electric elements allow for highly uniform heat distribution throughout the chamber. This eliminates the "hot spots" and "cold spots" that can cause uneven sintering, internal stress, and ultimately, a failed restoration.

Why This Precision is Non-Negotiable in Dentistry

A deviation of even a few degrees can have a dramatic impact on the final properties of dental ceramics like zirconia. The furnace's ±1°C accuracy is essential for several reasons.

Preventing Material Deformation and Cracks

Dental ceramics undergo significant shrinkage during sintering. If the temperature is not perfectly uniform, one part of the restoration will shrink faster than another, creating internal stresses that can lead to micro-cracks, warping, or complete fracture.

Precise control ensures the entire restoration heats and cools at a consistent rate, preserving its structural integrity.

Ensuring Aesthetic Consistency

Temperature directly influences the final translucency and shade of a restoration. A lack of precise control can result in a restoration that appears opaque, dull, or off-color.

By maintaining a stable temperature profile, the furnace ensures the material's optical properties develop as intended, leading to lifelike and predictable aesthetics.

Managing the Glass Phase

For certain ceramics, the sintering process involves a "glass phase" that must flow evenly to bind the crystalline particles.

Using a slow, controlled heating ramp—a key feature of these furnaces—is critical. It prevents the glass phase from flowing unevenly, which would create internal voids and weaken the final product.

Understanding the Trade-offs: Fast vs. Slow Sintering

The name "Fast Slow Dental Sintering Furnace" highlights its core utility: providing options. The furnace's precise control system is what makes both modes reliable.

The Advantage of Speed

Fast sintering cycles are designed for maximum efficiency. They are ideal for single-unit crowns and small cases where a rapid turnaround is the top priority for the lab or clinic.

These cycles rely on the furnace's ability to ramp up to and hold a high temperature with extreme accuracy, sintering the material quickly without compromising its basic strength.

The Necessity of Slowness

Slow sintering cycles prioritize ultimate quality and safety over speed. They are essential for large-span bridges, complex aesthetic cases, or materials known to be particularly sensitive.

The gradual heating and cooling minimizes all thermal stress, ensuring the highest possible flexural strength and optimal translucency. This is the mode of choice when the margin for error is zero.

The Role of Programmable Cycles

Most modern furnaces come with multiple pre-set and programmable cycles. This allows technicians to precisely match the sintering protocol to the specific material manufacturer's recommendations. The furnace's control system ensures it can execute these complex, multi-stage programs flawlessly.

Making the Right Choice for Your Goal

The furnace's dual-mode capability is not just a feature but a tool; your choice depends entirely on the clinical or lab requirement.

- If your primary focus is rapid turnaround for a single crown: Use the fast sintering mode, as its validated cycle is designed for efficiency without compromising the integrity of a standard restoration.

- If your primary focus is maximum aesthetic quality for an anterior case: Opt for a slower, pre-programmed cycle to ensure optimal translucency and prevent any potential for color deviation.

- If your primary focus is structural integrity for a large-span bridge: Always use the slow sintering mode to guarantee even heat distribution, minimize internal stresses, and prevent any risk of deformation.

Ultimately, the furnace's precise temperature control empowers you to choose the right balance between speed and quality for every unique case.

Summary Table:

| Component | Role in Precision Control | Key Benefit |

|---|---|---|

| PID Controller | Adjusts power dynamically for stable temperature | Prevents temperature fluctuations and ensures uniformity |

| High-Accuracy Sensors | Provide real-time temperature feedback | Enables continuous monitoring and correction |

| Electric Heating Elements | Deliver uniform heat distribution | Eliminates hot/cold spots for even sintering |

Elevate your dental lab's precision and efficiency with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering reliable results for flawless dental restorations. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations