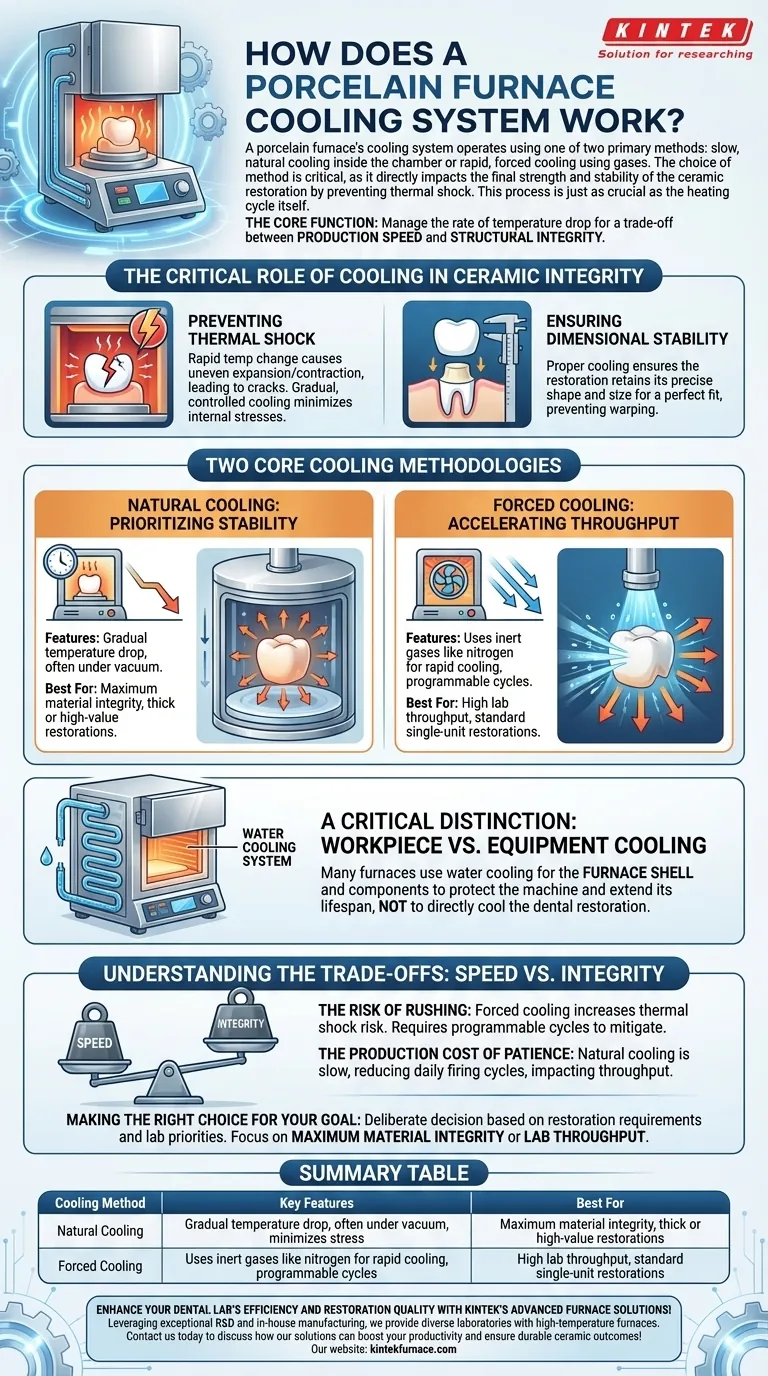

A porcelain furnace's cooling system operates using one of two primary methods: slow, natural cooling inside the chamber or rapid, forced cooling using gases. The choice of method is critical, as it directly impacts the final strength and stability of the ceramic restoration by preventing thermal shock. This process is just as crucial as the heating cycle itself.

The core function of cooling is not merely to lower the temperature, but to manage the rate of that temperature drop. The fundamental choice is a trade-off between production speed and the structural integrity of the final ceramic restoration.

The Critical Role of Cooling in Ceramic Integrity

The intense heat of a porcelain furnace, often exceeding 1,200°C (2,200°F), creates immense thermal stress in the dental ceramic. How this heat is removed determines the success or failure of the restoration.

Preventing Thermal Shock

Thermal shock occurs when a material experiences a rapid temperature change, causing different parts to expand or contract at different rates. In dental porcelain, this leads to microscopic or even visible cracks, compromising the entire restoration.

Gradual, controlled cooling allows the entire piece to contract uniformly, minimizing internal stresses and preventing fractures.

Ensuring Dimensional Stability

The final fit of a crown, veneer, or bridge is paramount. If the restoration cools too quickly or unevenly, it can warp or distort.

Dimensional stability means the restoration retains its precise shape and size as it cools. A proper cooling cycle ensures the restoration that comes out of the furnace will fit the patient's preparation perfectly.

Two Core Cooling Methodologies

Porcelain furnaces employ distinct strategies to bring restorations from firing temperature back to room temperature. Each has a specific purpose and application.

Natural Cooling: Prioritizing Stability

Natural cooling is the most straightforward and often safest method. The furnace simply deactivates its heating elements and allows the chamber to cool down gradually.

This process often occurs under a vacuum, insulating the workpiece from rapid temperature drops and allowing heat to dissipate slowly and evenly. This prioritizes the structural integrity of the ceramic above all else.

Forced Cooling: Accelerating Throughput

For high-volume labs, waiting for natural cooling is a bottleneck. Forced cooling systems accelerate the process to increase productivity.

These systems introduce a cool, inert gas, such as nitrogen, into the firing chamber. This actively draws heat away from the restoration faster than natural convection alone, shortening the overall cycle time.

A Critical Distinction: Workpiece vs. Equipment Cooling

It is vital to understand that some cooling systems protect the furnace itself, not the ceramic restoration.

Many furnaces incorporate a water cooling system. This system circulates water through the furnace shell, cover, and around the heating elements. Its sole purpose is to protect the machine's components from overheating and extend the equipment's lifespan. This system does not directly cool the dental restoration inside the chamber.

Understanding the Trade-offs: Speed vs. Integrity

The choice between natural and forced cooling is a calculated decision based on production needs and material requirements.

The Risk of Rushing the Process

The primary drawback of forced cooling is the increased risk of thermal shock. If the cooling rate is too aggressive for the specific ceramic material or the thickness of the restoration, it can induce stress and cause cracking.

Modern furnaces have highly programmable forced cooling cycles to mitigate this risk, but the danger is inherent to the process.

The Production Cost of Patience

Natural cooling is exceptionally safe for the ceramic but is also very slow. This ties up the furnace for longer periods, reducing the number of firing cycles a lab can complete in a day.

For a busy lab, this reduction in throughput can have significant financial implications.

Making the Right Choice for Your Goal

Your choice of cooling protocol should be a deliberate decision aligned with the specific requirements of the restoration and your lab's operational priorities.

- If your primary focus is maximum material integrity: For thick, complex, or high-value restorations, a slow, natural cooling cycle is the safest path to prevent remakes and ensure stability.

- If your primary focus is lab throughput: For standard, single-unit restorations made from robust materials, a well-calibrated forced cooling program can safely increase your lab's daily production capacity.

Ultimately, mastering the cooling cycle is essential for transforming a properly fired restoration into a clinically successful and durable final product.

Summary Table:

| Cooling Method | Key Features | Best For |

|---|---|---|

| Natural Cooling | Gradual temperature drop, often under vacuum, minimizes stress | Maximum material integrity, thick or high-value restorations |

| Forced Cooling | Uses inert gases like nitrogen for rapid cooling, programmable cycles | High lab throughput, standard single-unit restorations |

Enhance your dental lab's efficiency and restoration quality with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how our solutions can boost your productivity and ensure durable ceramic outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique