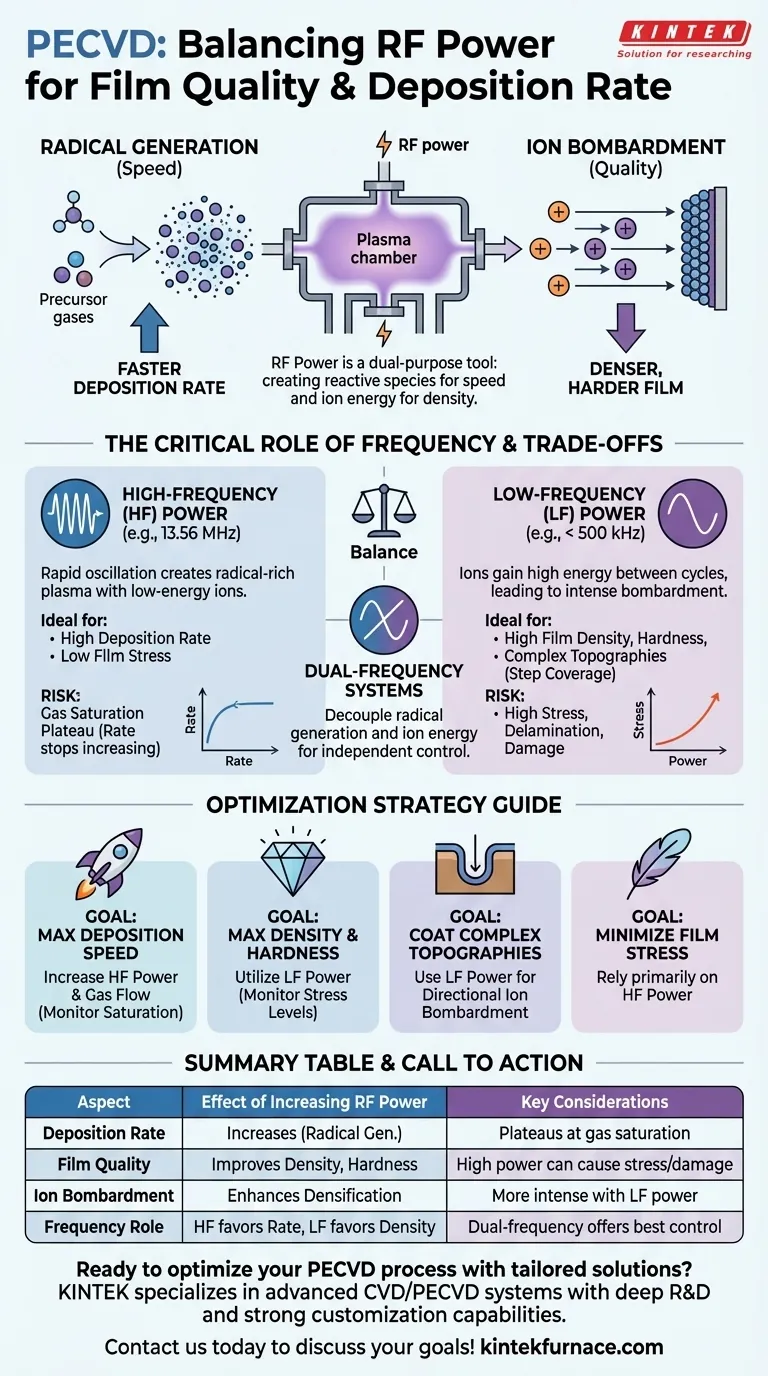

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), increasing RF power is a primary method for controlling your process, directly influencing both the film's deposition rate and its final quality. Higher power enhances the plasma's energy, which simultaneously accelerates the rate of film growth and increases the energy of ion bombardment, leading to a denser, more robust film structure. However, this relationship is not linear and involves critical trade-offs.

The central challenge is that RF power is not a single-purpose knob. It controls two distinct physical effects: the creation of reactive species that drive deposition speed, and the ion energy that dictates film density and stress. Mastering your PECVD process requires balancing these two effects to achieve your specific goal.

The Dual Role of RF Power in Plasma

RF power is the engine of the PECVD process. Understanding how it energizes the plasma is key to manipulating the outcome. It performs two critical functions at once.

Driving Deposition Rate via Radical Generation

The primary purpose of the plasma is to break down stable precursor gases into highly reactive chemical species known as free radicals.

These radicals are the essential building blocks for the film. Increasing the RF power injects more energy into the plasma, leading to more frequent and energetic collisions. This increases the concentration of free radicals, which in turn increases the rate at which they arrive and bond to the substrate, accelerating film growth.

Enhancing Film Quality via Ion Bombardment

In addition to neutral radicals, the plasma also creates positive ions. The electric field generated by the RF power accelerates these ions toward the substrate, which is typically held at a different potential.

This process, known as ion bombardment, acts like a microscopic hammer, compacting the atoms of the growing film. This physical densification improves key material properties such as hardness, refractive index, and chemical resistance. Higher RF power generally leads to higher ion energy and a denser, higher-quality film.

Reaching the Point of Diminishing Returns

Simply increasing the power indefinitely is not a viable strategy. You will quickly encounter physical limits and detrimental side effects that can compromise your results.

The Deposition Rate Plateau

The increase in deposition rate with power is not infinite. At a certain power level, you will have dissociated nearly all the available precursor gas molecules into radicals.

Once the reaction gas is fully ionized and radicals are saturated, adding more power will not create more building blocks. At this point, the deposition rate will plateau. The process becomes "mass-transport limited," meaning the rate is now constrained by the flow rate of precursor gas into the chamber, not the power.

The Stress and Damage Threshold

While ion bombardment is beneficial for densification, excessive energy can be destructive. Very high power levels lead to intense bombardment that can induce high compressive stress in the film, potentially causing delamination or cracking.

In extreme cases, the ion energy can become high enough to physically sputter atoms away from the growing film, damaging its structure and even slowing the net deposition rate.

Understanding the Trade-offs: The Critical Impact of Frequency

The most important nuance in controlling RF power is understanding the role of frequency. The behavior of the plasma changes dramatically depending on the frequency used, as it dictates how effectively ions can respond to the electric field.

High-Frequency (HF) Power (e.g., 13.56 MHz)

At high frequencies, the electric field oscillates too rapidly for the heavy ions to fully accelerate between cycles. The result is a plasma rich in free radicals but with relatively low-energy ion bombardment.

HF power is therefore ideal for processes where the main goal is a high deposition rate with minimal induced film stress.

Low-Frequency (LF) Power (e.g., < 500 kHz)

At lower frequencies, the ions have enough time during each cycle to accelerate to very high energies before hitting the substrate. This leads to intense, high-energy ion bombardment.

LF power is superior for creating exceptionally dense and hard films. It is also critical for coating complex topographies, as the highly directional ions improve "step coverage" into deep trenches and features. The trade-off is often a lower deposition rate and significantly higher film stress.

The Power of Dual-Frequency Systems

Many advanced PECVD systems use a mixture of HF and LF power. This approach decouples radical generation from ion energy, offering independent control. The HF power maintains a high density of radicals for a fast deposition rate, while the LF power is used to precisely tune the ion bombardment energy to achieve the desired film density and stress.

Making the Right Choice for Your Process

Optimizing your PECVD recipe requires aligning your RF power strategy with your primary objective.

- If your primary focus is maximizing deposition speed: Increase HF power and precursor gas flow, but monitor for the saturation plateau where further power increases offer no benefit.

- If your primary focus is achieving the highest film density and hardness: Utilize lower-frequency (LF) power to increase ion bombardment energy, but be mindful of inducing excessive film stress.

- If your primary focus is coating complex topographies (like trenches): Low-frequency (LF) power is superior, as the directional ion bombardment improves step coverage.

- If your primary focus is minimizing film stress: Rely primarily on high-frequency (HF) power, which efficiently generates radicals without excessive ion energy.

By treating RF power and frequency as precise tools to tune radical generation and ion energy, you can move from simple recipes to predictable materials engineering.

Summary Table:

| Aspect | Effect of Increasing RF Power | Key Considerations |

|---|---|---|

| Deposition Rate | Increases due to higher radical concentration | Plateaus when precursor gas is saturated |

| Film Quality | Improves density, hardness, and chemical resistance | High power can cause stress, delamination, or damage |

| Ion Bombardment | Enhances film densification | More intense with low-frequency power; can be destructive at extremes |

| Frequency Role | High frequency favors deposition rate; low frequency favors film density | Dual-frequency systems offer independent control for optimization |

Ready to optimize your PECVD process with tailored solutions? KINTEK specializes in advanced CVD/PECVD systems, leveraging our deep R&D and in-house manufacturing to deliver high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and more. Our strong customization capabilities ensure we meet your unique experimental needs, enhancing film quality and deposition efficiency. Contact us today to discuss how we can support your laboratory's goals!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods