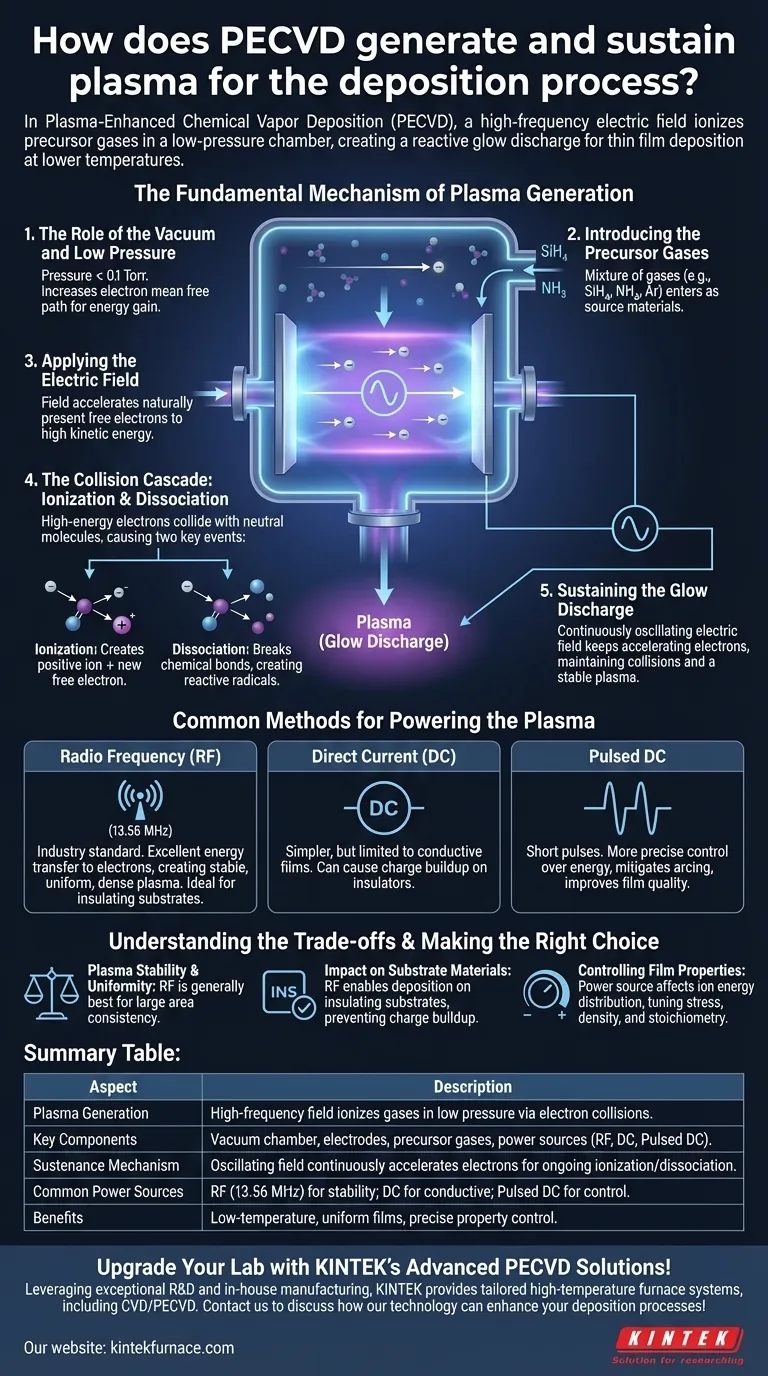

In Plasma-Enhanced Chemical Vapor Deposition (PECVD), plasma is generated by applying a high-frequency electric field between two electrodes within a low-pressure chamber. This electrical energy ionizes and breaks apart precursor gas molecules, creating a reactive "glow discharge." This process allows for the deposition of thin films at significantly lower temperatures than traditional methods.

The core purpose of plasma in PECVD is not to heat the chamber, but to use electrical energy to create a highly reactive chemical soup. This enables the breakdown of stable gases into the building blocks for film deposition, a task that would otherwise require extreme heat.

The Fundamental Mechanism of Plasma Generation

To understand PECVD, you must first understand the step-by-step process that transforms inert gas into a chemically active plasma. This occurs in a controlled vacuum environment.

The Role of the Vacuum and Low Pressure

The entire process takes place in a vacuum chamber at very low pressures, often below 0.1 Torr.

This low pressure is critical. It increases the mean free path, which is the average distance an electron can travel before colliding with a gas molecule. A longer path allows electrons to gain more energy from the electric field before impact.

Introducing the Precursor Gases

A precise mixture of precursor gases is introduced into the chamber. These are the source materials for the film.

For example, to deposit silicon nitride (SiNₓ), gases like silane (SiH₄) and ammonia (NH₃) or nitrogen (N₂) are used. These are typically mixed with inert carrier gases like argon.

Applying the Electric Field

An electric field is applied between two electrodes inside the chamber. This field immediately acts on the few free electrons naturally present in the gas.

The field accelerates these electrons to high speeds, giving them significant kinetic energy.

The Collision Cascade: Ionization and Dissociation

These high-energy electrons collide with the neutral precursor gas molecules. These collisions are the heart of plasma generation and result in two key events:

- Ionization: An electron strikes a neutral molecule with enough force to knock another electron loose. This creates a positive ion and a new free electron, which then also accelerates in the field.

- Dissociation: The collision's energy breaks the chemical bonds of the precursor molecules, creating highly reactive neutral fragments called radicals.

This process repeats in a rapid cascade, quickly filling the chamber with a mixture of ions, electrons, radicals, and neutral molecules. This energized, quasi-neutral gas is the plasma, often visible as a characteristic glow.

Sustaining the Glow Discharge

To sustain the plasma, a continuously oscillating electric field is used. By rapidly switching polarity, the field keeps accelerating electrons back and forth, ensuring collisions continue to occur.

This constant energy input balances out the energy lost as ions and radicals recombine or deposit onto the substrate, maintaining a stable plasma for the duration of the deposition process.

Common Methods for Powering the Plasma

The characteristics of the plasma, and therefore the properties of the resulting film, are heavily influenced by the type of power supply used to create the electric field.

Radio Frequency (RF): The Industry Standard

The most common method uses a Radio Frequency (RF) power source, typically operating at a federally regulated industrial frequency of 13.56 MHz.

RF is highly effective because its rapid oscillation is excellent at transferring energy to the light electrons while the heavier ions remain relatively stationary. This creates a stable, uniform, and dense plasma, ideal for high-quality films on both conductive and insulating substrates.

Direct Current (DC) and Pulsed DC

A Direct Current (DC) voltage can also generate plasma. This is a simpler method but is generally limited to depositing conductive films, as charge can build up on insulating substrates, disrupting the process.

Pulsed DC is an advancement that applies the DC voltage in short pulses. This provides more precise control over the plasma energy and can help mitigate issues like arcing, improving film quality.

Other Frequencies and Sources

While less common, other sources like Medium Frequency (MF) and microwaves can also be used. Each offers a different way to couple energy into the gas, creating plasmas with distinct densities and ion energy distributions tailored for specific applications.

Understanding the Trade-offs: Why the Method Matters

Choosing a power source is not arbitrary; it is a critical engineering decision that dictates the capabilities of the PECVD system and the quality of the film.

Plasma Stability and Uniformity

RF systems generally produce the most stable and spatially uniform plasma over large areas. This is essential for manufacturing applications where consistency across a wafer is paramount. DC plasmas can sometimes be less uniform.

Impact on Substrate Materials

The primary advantage of RF over DC is its ability to deposit films on insulating substrates. The oscillating field prevents the destructive charge buildup that can occur with a constant DC voltage, making RF-PECVD far more versatile.

Controlling Film Properties

The choice of power source directly impacts the ion energy distribution within the plasma. Advanced techniques like pulsed DC or dual-frequency RF allow operators to finely tune ion energy and plasma density.

This control allows for precise manipulation of film properties like stress, density, stoichiometry, and hardness. Higher ion energy can create denser films but may also introduce damage to the substrate.

Making the Right Choice for Your Goal

The optimal plasma generation method depends entirely on the material being deposited and the desired film characteristics.

- If your primary focus is uniform, high-quality films on insulating substrates: RF-PECVD is the industry-standard and most reliable choice.

- If your primary focus is precise control over film stress and density: A system with pulsed DC or advanced RF capabilities provides the necessary levers to tune plasma chemistry.

- If your primary focus is a simple setup for conductive films: DC-PECVD can be a viable, though less common, option for specific research or industrial needs.

Ultimately, understanding how plasma is generated transforms it from a "black box" into a tunable and powerful tool for materials engineering.

Summary Table:

| Aspect | Description |

|---|---|

| Plasma Generation | High-frequency electric field ionizes gases in a low-pressure chamber, creating reactive plasma via electron collisions. |

| Key Components | Vacuum chamber, electrodes, precursor gases (e.g., SiH₄, NH₃), and power sources (RF, DC, pulsed DC). |

| Sustenance Mechanism | Oscillating electric field maintains plasma by continuously accelerating electrons for ongoing ionization and dissociation. |

| Common Power Sources | RF (13.56 MHz) for stability and versatility; DC for conductive films; pulsed DC for enhanced control. |

| Benefits | Enables low-temperature deposition, uniform film quality, and precise control over properties like stress and density. |

Upgrade Your Lab with KINTEK's Advanced PECVD Solutions! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems, including our specialized CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for thin-film deposition, material engineering, or research applications. Contact us today to discuss how our PECVD technology can enhance your deposition processes and drive innovation in your projects!

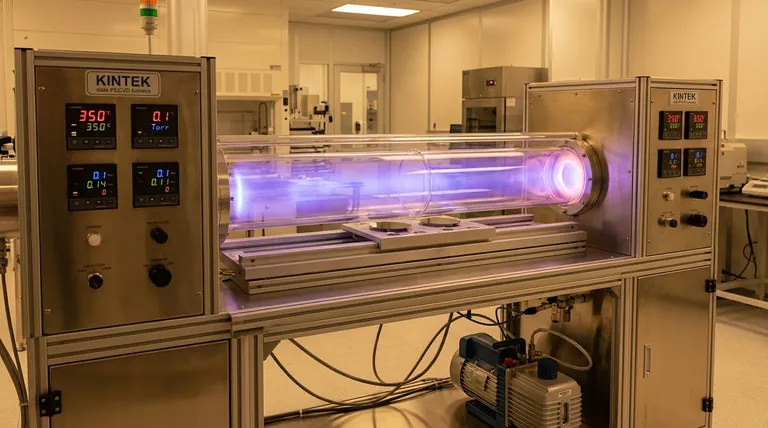

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications