At its core, a Vacuum Induction Melting (VIM) furnace uses a powerful, fluctuating magnetic field to generate heat directly within the metal itself. An alternating electrical current is passed through a copper coil, which creates the magnetic field. This field induces strong electrical currents, known as eddy currents, inside the metal charge, and the metal's natural resistance to these currents generates intense, rapid heat, causing it to melt—all while inside a vacuum chamber that prevents contamination.

The true power of a VIM furnace is not just its ability to melt metal without direct contact, but its unique combination of this clean, efficient heating method with a vacuum environment. This synergy allows for the production of exceptionally pure, high-performance alloys that are impossible to create using conventional atmospheric melting techniques.

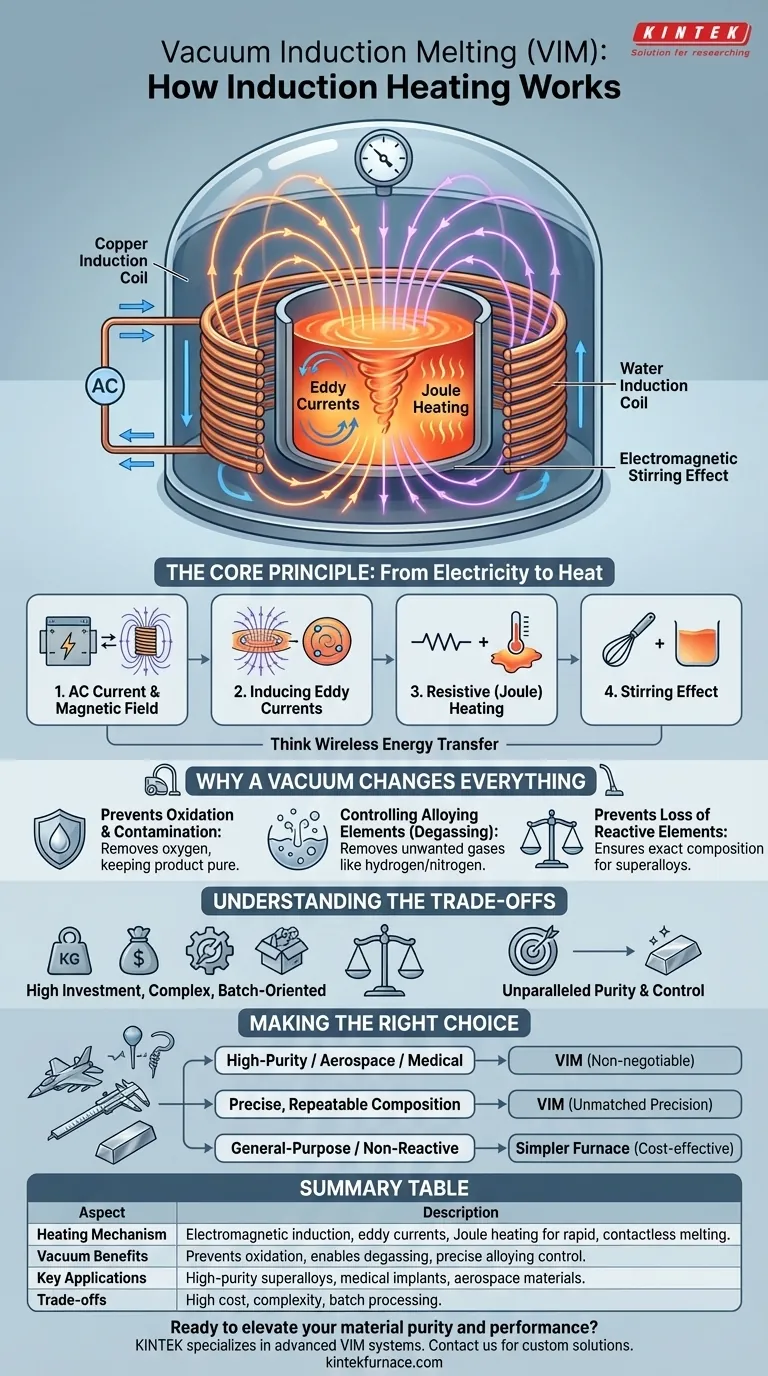

The Core Principle: From Electricity to Heat

To understand the VIM process, it's best to break it down into a sequence of events. The entire process is a direct application of Faraday's law of induction and the Joule heating effect.

The Induction Coil and the Magnetic Field

An induction furnace begins with a large, water-cooled copper coil. A specialized power supply drives a high-frequency alternating current (AC) through this coil.

As the current rapidly switches direction, it generates a powerful and fluctuating magnetic field in the space within and around the coil, where the crucible containing the metal is placed.

Inducing Eddy Currents in the Metal

This rapidly changing magnetic field penetrates the conductive metal charge held within the crucible. This, in turn, induces a circular flow of electrons—or eddy currents—directly within the surface of the metal.

Think of it as a wireless energy transfer. The coil acts as the transmitter, and the metal itself becomes the receiver, converting magnetic energy into electrical energy.

Resistive Heating

All metals have some inherent electrical resistance. As the strong eddy currents flow through the metal, they encounter this resistance, which generates immense heat.

This phenomenon, known as Joule heating, is what melts the metal. The heating is extremely rapid and efficient because it originates inside the material, not from an external flame or heating element.

The Stirring Effect

A valuable secondary benefit of the magnetic field is that it physically stirs the molten metal. This electromagnetic stirring action ensures the melt is chemically and thermally homogenous, which is critical for creating consistent, high-quality alloys.

Why a Vacuum Changes Everything

The "vacuum" component of VIM is what elevates it from a simple melting technique to a sophisticated refining process. By removing air and other gases from the furnace chamber, a series of critical advantages are unlocked.

Preventing Oxidation and Contamination

Atmospheric air contains about 21% oxygen, which readily reacts with hot metals to form oxides (impurities). The vacuum environment eliminates this oxygen, preventing oxidation and keeping the final product pure.

This also prevents contamination from other atmospheric gases like nitrogen, which can be detrimental to certain alloys.

Controlling Alloying Elements

The vacuum allows for the precise removal of unwanted dissolved gases, such as hydrogen and nitrogen, from the molten metal, a process known as degassing.

Furthermore, it prevents the loss of reactive alloying elements (like aluminum and titanium in superalloys) that would otherwise burn off in an air atmosphere. This ensures the final composition meets exact specifications with very tight tolerances.

Understanding the Trade-offs

While VIM technology offers unparalleled benefits for purity and control, it's essential to understand its associated trade-offs.

High Initial Investment

VIM systems are complex and expensive. The furnace itself, along with the required high-capacity vacuum pumps, sophisticated power supplies, and control systems, represents a significant capital investment compared to simpler furnace types.

Operational Complexity

Operating a VIM furnace requires highly skilled personnel. Managing the vacuum levels, power cycles, temperature, and alloy additions is a complex process that demands precision and expertise to ensure both safety and product quality.

Batch-Oriented Process

VIM furnaces are inherently batch-based, making them incredibly flexible for producing various alloys in different quantities. However, they are not suited for the continuous, high-volume production typical of industries like structural steel, which use methods like blast furnaces.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on the desired quality and application of the final product.

- If your primary focus is producing high-purity superalloys, medical implants, or aerospace-grade materials: A VIM furnace is non-negotiable, as it is the only way to achieve the required cleanliness and compositional accuracy.

- If your primary focus is creating alloys with precise, repeatable chemical compositions: The control over atmospheric reactions and degassing offered by VIM provides unmatched precision.

- If your primary focus is general-purpose melting of non-reactive metals where some impurity is acceptable: A simpler and less expensive non-vacuum induction furnace or even a traditional fuel-fired furnace may be more cost-effective.

Ultimately, choosing a VIM furnace is a strategic decision to prioritize material purity and performance above all else.

Summary Table:

| Aspect | Description |

|---|---|

| Heating Mechanism | Uses electromagnetic induction to generate eddy currents and Joule heating inside the metal for rapid, contactless melting. |

| Vacuum Benefits | Prevents oxidation and contamination, enables degassing, and allows precise control of alloying elements. |

| Key Applications | Ideal for high-purity superalloys, medical implants, and aerospace materials requiring tight compositional tolerances. |

| Trade-offs | High initial cost, operational complexity, and batch processing limit suitability for high-volume production. |

Ready to elevate your material purity and performance? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum Induction Melting systems. With our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—perfect for aerospace, medical, and research labs. Contact us today to discuss how our VIM furnaces can deliver precise, contamination-free results for your high-performance alloys!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What makes induction furnaces suitable for smelting platinum group metals (PGMs)? Achieve Purity and Precision in Metal Processing

- How do induction furnaces improve working conditions? A Safer, Cleaner Foundry Environment

- How does VIM compare to DIM for LTES composites? Unlock Superior Thermal Storage and Stability

- What are the two types of induction furnaces? Channel vs. Coreless Furnace Explained

- Why is multiple melting required in a vacuum arc furnace? Achieve Uniform Ni-Mn-Ga Shape Memory Alloys

- Why are vacuum casting furnaces considered vital for modern manufacturing? Unlock Purity and Performance

- What are the risks of induction furnace? Managing Thermal, Electrical, and EMF Hazards

- How does the vacuum environment contribute to metal quality in VIM furnaces? Achieve Superior Purity and Performance