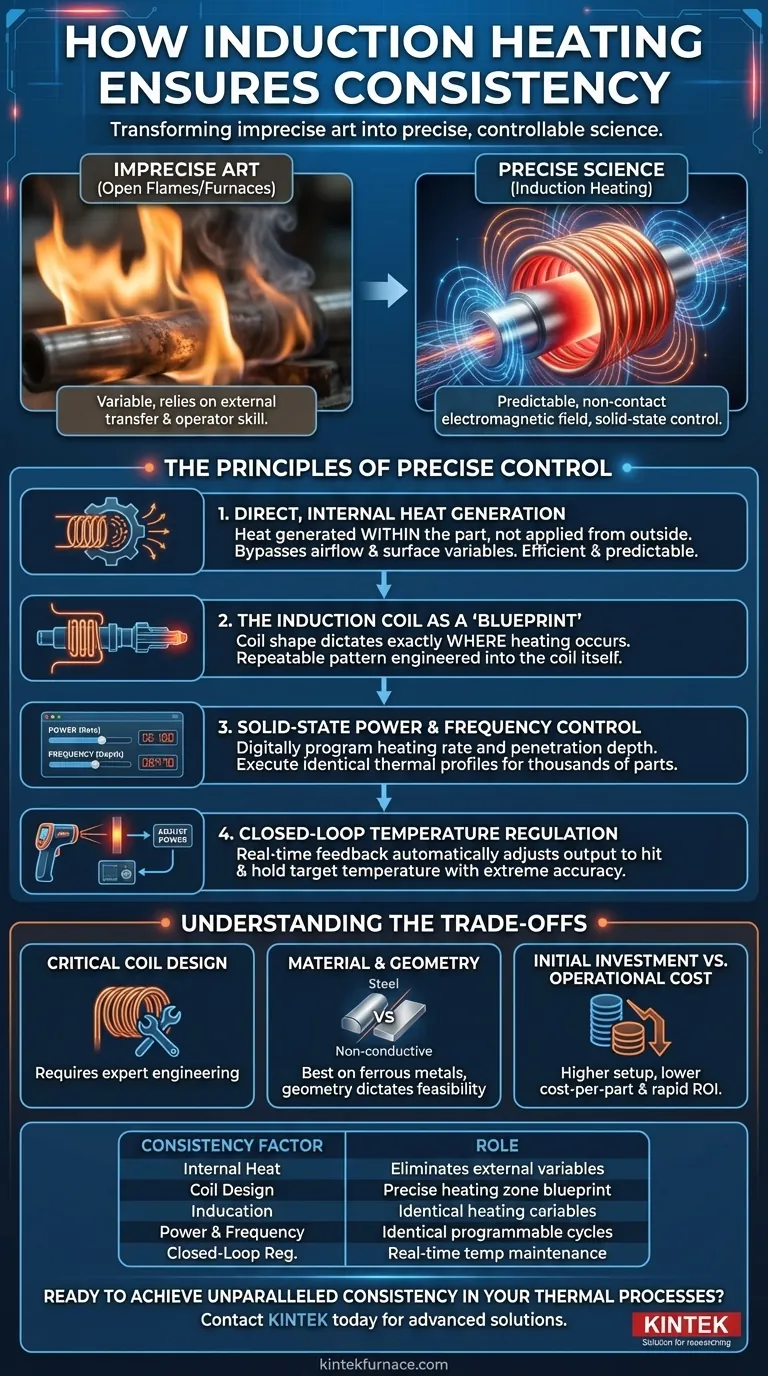

At its core, induction heating ensures consistency by transforming the heating process from an imprecise art into a precise, controllable science. Unlike open flames or furnaces that rely on external heat transfer, induction uses a non-contact electromagnetic field to generate heat directly within the part itself, allowing for unparalleled control over the location, amount, and rate of heating.

Inconsistent heating is a process control problem. Induction solves this by replacing the variability of flames and operator skill with the predictable physics of electromagnetism, managed by modern solid-state electronics. This makes consistent, repeatable results an inherent feature of the system, not a matter of chance.

The Principles of Precise Control

To understand induction's consistency, you must understand how it controls the flow of energy. The process is governed by several distinct factors that work together to eliminate guesswork.

Direct, Internal Heat Generation

The fundamental difference is that induction does not apply heat from an external source. Instead, an alternating magnetic field induces electrical eddy currents inside the conductive workpiece. The material's natural resistance to these currents generates instantaneous, internal heat.

This method bypasses the variables of external heat transfer, such as airflow or surface contamination, resulting in a much more efficient and predictable heating cycle from the very start.

The Induction Coil as a Heat "Blueprint"

The induction coil, typically made of copper tubing, acts as the primary tool for control. The shape, size, and proximity of the coil to the part create a magnetic field that precisely dictates where the heating occurs.

This allows you to heat a specific zone of a complex part—like the tip of a shaft or the threads on a bolt—without affecting the surrounding material. The heating pattern is engineered into the coil itself, making it repeatable every single time.

Solid-State Power and Frequency Control

Modern induction heaters use solid-state power supplies, which are the brains of the operation. These systems allow operators to precisely program and control the key variables of the process: power output and frequency.

Changing the power level controls the rate of heating, while adjusting the frequency changes the depth of heat penetration. This level of digital control means you can design a specific thermal ramp-up, hold, and cool-down profile and execute it identically for thousands of parts.

Closed-Loop Temperature Regulation

For the highest degree of precision, induction systems integrate with temperature sensors like infrared pyrometers. This creates a closed-loop feedback system.

The sensor constantly measures the part's temperature and feeds that data back to the power supply. The system then automatically adjusts its power output in real-time to hit a target temperature and hold it with extreme accuracy, preventing both under-heating and over-heating.

Understanding the Trade-offs

While powerful, the consistency of induction heating is not automatic. It depends on a properly engineered system, and it comes with specific considerations.

The Critical Role of Coil Design

An improperly designed coil is the most common cause of poor results. If the coil is not correctly coupled to the part, it will produce uneven heating, defeating the primary benefit of the technology. Consistency is contingent on expert coil design tailored to the specific part geometry.

Material and Geometry Constraints

Induction works best on electrically conductive materials, primarily ferrous metals like steel and iron. Its effectiveness on materials like aluminum or copper is lower and requires different frequencies and power levels. The geometry of the part also dictates the feasibility and complexity of the coil design.

Initial Investment vs. Operational Cost

The initial capital cost for an induction heating system and its custom coils is typically higher than for a simple torch setup or a basic furnace. However, its high energy efficiency, speed, and repeatability often lead to a lower cost-per-part and a rapid return on investment in production environments.

Making the Right Choice for Your Goal

Deciding if induction is the correct solution requires aligning its capabilities with your primary objective.

- If your primary focus is high-volume production with tight tolerances: Induction is the definitive choice for its unmatched repeatability, speed, and potential for full automation.

- If your primary focus is process control and data logging: The digital nature of induction systems allows for precise monitoring and recording of every heating cycle, which is critical for quality assurance in industries like aerospace and medical.

- If your primary focus is workplace safety and efficiency: Induction's flameless, localized heating creates a cooler, cleaner, and safer work environment while minimizing wasted energy.

- If your primary focus is one-off jobs or repairing varied parts: The need for part-specific coils can make induction less practical than a more flexible (though less precise) method like a torch.

Ultimately, adopting induction heating is a decision to take direct, scientific control over your thermal processes.

Summary Table:

| Factor | Role in Ensuring Consistency |

|---|---|

| Internal Heat Generation | Generates heat directly within the part, eliminating external variables. |

| Coil Design | Acts as a precise blueprint, dictating the exact heating zone. |

| Power & Frequency Control | Programmable controls manage heating rate and depth for identical cycles. |

| Closed-Loop Temperature Regulation | Real-time feedback automatically adjusts power to maintain target temperature. |

Ready to achieve unparalleled consistency in your thermal processes?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions. Our product line, including Muffle, Tube, and Rotary Furnaces, as well as Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities. We can design a system tailored to your unique conductive materials and geometric requirements, ensuring precise, repeatable results for your high-volume production or quality-critical applications.

Contact us today to discuss how our expertise can bring scientific control and reliability to your lab or production floor.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies