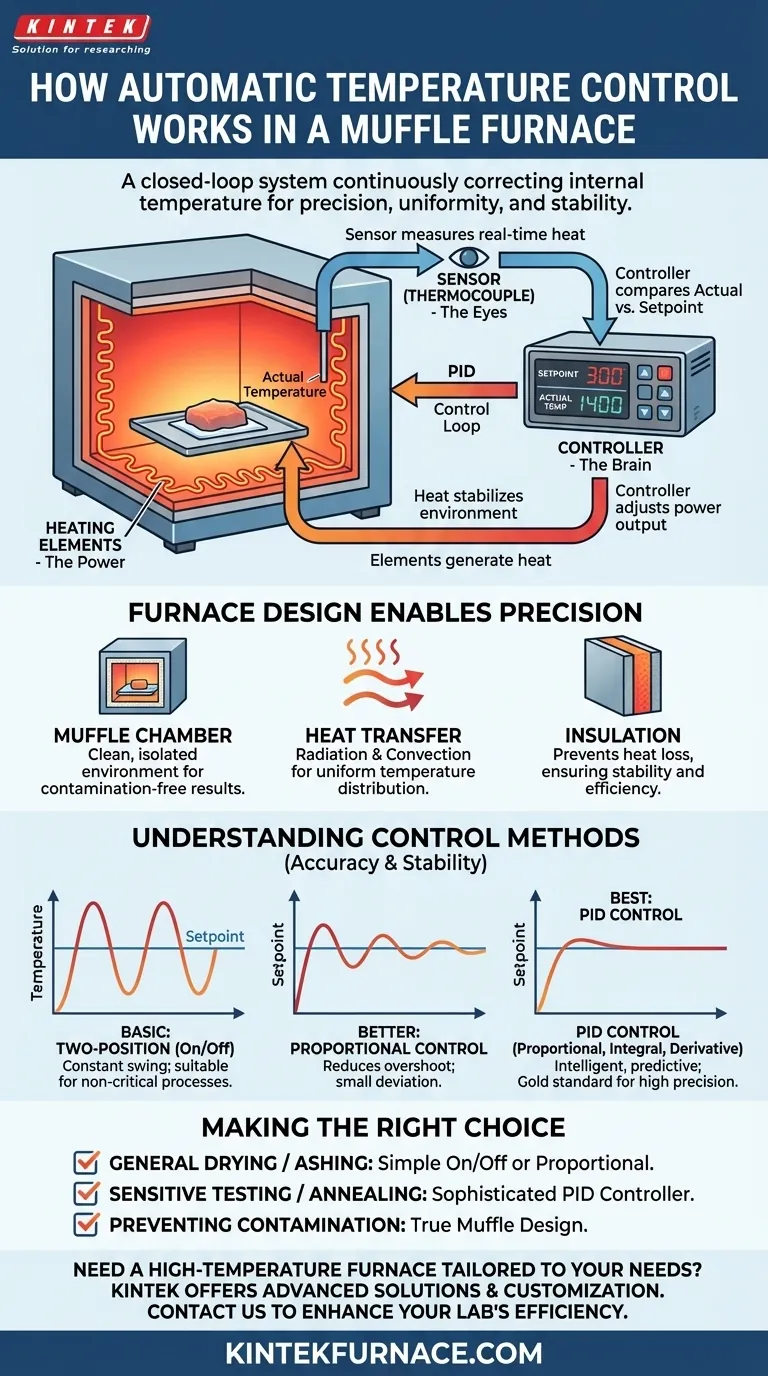

Automatic temperature control in a muffle furnace is a closed-loop system that continuously corrects the internal temperature. A sensor measures the actual heat, a digital controller compares this value to your desired setpoint, and the system then adjusts the electrical power to the heating elements to either increase or decrease heat output, ensuring a stable thermal environment.

A muffle furnace's value lies not just in reaching high temperatures, but in maintaining them with extreme precision and uniformity. The automatic control system is the brain, but it relies on the furnace's insulated design and efficient heating elements to deliver a stable, contamination-free environment for repeatable results.

The Anatomy of a Control System

A muffle furnace's ability to maintain a precise temperature is not the result of a single component, but the interaction of three critical parts working in a constant feedback loop.

The Sensor: The Eyes of the System

The entire control process begins with a sensor, most commonly a thermocouple. This device is placed inside the heating chamber to get an accurate, real-time reading of the internal temperature.

The thermocouple's sole job is to constantly report the "actual temperature" back to the controller.

The Controller: The Brain of the Operation

The controller is the central decision-maker. It performs one simple but critical task: it compares the actual temperature (from the thermocouple) with the desired temperature (the setpoint you entered).

Based on the difference, or "error," between these two values, the controller calculates the necessary adjustment and sends a command to the heating elements.

The Heating Elements: The Source of Power

Lining the chamber walls are high-resistance wires, typically made of nichrome or silicon carbide. When the controller sends them an electrical current, they glow red-hot, generating the furnace's heat.

The controller modulates the amount of power sent to these elements. If the furnace is too cool, it increases power; if it's too hot, it decreases or cuts off the power entirely.

How the Furnace Design Enables Precision

The control system can only be effective if the furnace itself is designed to hold and distribute heat efficiently. The physical construction is just as important as the electronic controls.

The Muffle: A Clean, Isolated Environment

The term "muffle" refers to the inner chamber, typically made of a ceramic material, that isolates your sample. It separates the material from the raw heating elements and any potential gases or byproducts.

This design is essential for applications like ashing or calcination, where a clean and controlled heating environment is necessary for accurate results.

Heat Transfer: Convection and Radiation

The furnace ensures uniform temperature through two heat transfer mechanisms. Radiation is direct heat traveling in waves from the hot elements to the sample, while convection is the circulation of hot air within the chamber.

This dual-action approach minimizes "hot spots" and "cold spots," ensuring your entire sample experiences the same thermal conditions.

Insulation: The Key to Stability

The muffle chamber is wrapped in thick layers of high-performance insulation. This material is critical for preventing heat loss to the outside environment.

By trapping heat, the insulation creates a highly stable thermal environment. This stability makes the controller's job easier, allowing for finer adjustments and greater energy efficiency.

Understanding the Control Methods

Not all controllers are created equal. The method used to calculate temperature adjustments determines the furnace's accuracy and stability.

Basic: Two-Position (On/Off) Control

This is the simplest method. If the temperature is below the setpoint, the heating elements are 100% on. Once it passes the setpoint, they turn 100% off.

This crude approach results in a constant temperature oscillation, or "swing," around the setpoint. It's suitable for processes where exact temperature is not critical.

Better: Proportional Control

Proportional control is more sophisticated. As the temperature gets closer to the setpoint, the controller proportionally reduces the power to the heating elements.

This throttles the heating rate, significantly reducing the temperature overshoot seen in on/off systems. However, it can sometimes result in a small but steady temperature deviation just below the setpoint.

Best: PID Control

PID (Proportional-Integral-Derivative) control is the gold standard for high-precision applications. It combines three actions:

- Proportional (P): Reacts to the current temperature error.

- Integral (I): Corrects for past errors, eliminating the small deviation seen in proportional-only systems.

- Derivative (D): Predicts future errors based on the rate of temperature change, preventing overshoot.

This intelligent, predictive method allows the furnace to reach the setpoint quickly, with minimal overshoot, and hold it with exceptional stability.

Making the Right Choice for Your Goal

The level of temperature control you require is directly tied to the sensitivity of your process.

- If your primary focus is general drying or basic ashing: A furnace with simple on/off or proportional control is often sufficient and more cost-effective.

- If your primary focus is sensitive material testing, annealing, or sintering: You must prioritize a furnace with a sophisticated PID controller to ensure the highest accuracy and repeatability.

- If your primary focus is preventing sample contamination: Ensure the furnace uses a true muffle design that fully isolates your material from the heating elements.

Understanding how these systems work empowers you to select a tool that delivers not just heat, but the precise, stable, and clean thermal environment your work demands.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Sensor | Measures actual temperature | Thermocouple for real-time readings |

| Controller | Compares and adjusts temperature | PID control for high precision |

| Heating Elements | Generates heat | Nichrome or silicon carbide materials |

| Furnace Design | Ensures uniform heating | Insulation, muffle chamber for isolation |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, delivering superior temperature control and contamination-free environments. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment