At its core, an atmosphere furnace gives researchers ultimate control. It is a critical tool for research and development because it allows scientists to subject materials to extreme heat within a precisely managed gaseous environment. This unique capability enables the synthesis of entirely new materials, the optimization of existing ones, and the simulation of specific operational conditions, driving innovation across materials science, energy, and manufacturing.

An atmosphere furnace is more than just a high-temperature oven; it is a controlled environment simulator. Its true value in R&D lies in its ability to isolate variables, allowing researchers to observe how specific gases at high temperatures fundamentally alter a material's structure, properties, and performance.

The Foundation of Modern Materials Science

An atmosphere furnace is the instrument that turns theoretical material concepts into tangible reality. Its function is to control the two most powerful agents of change for materials: heat and chemical environment.

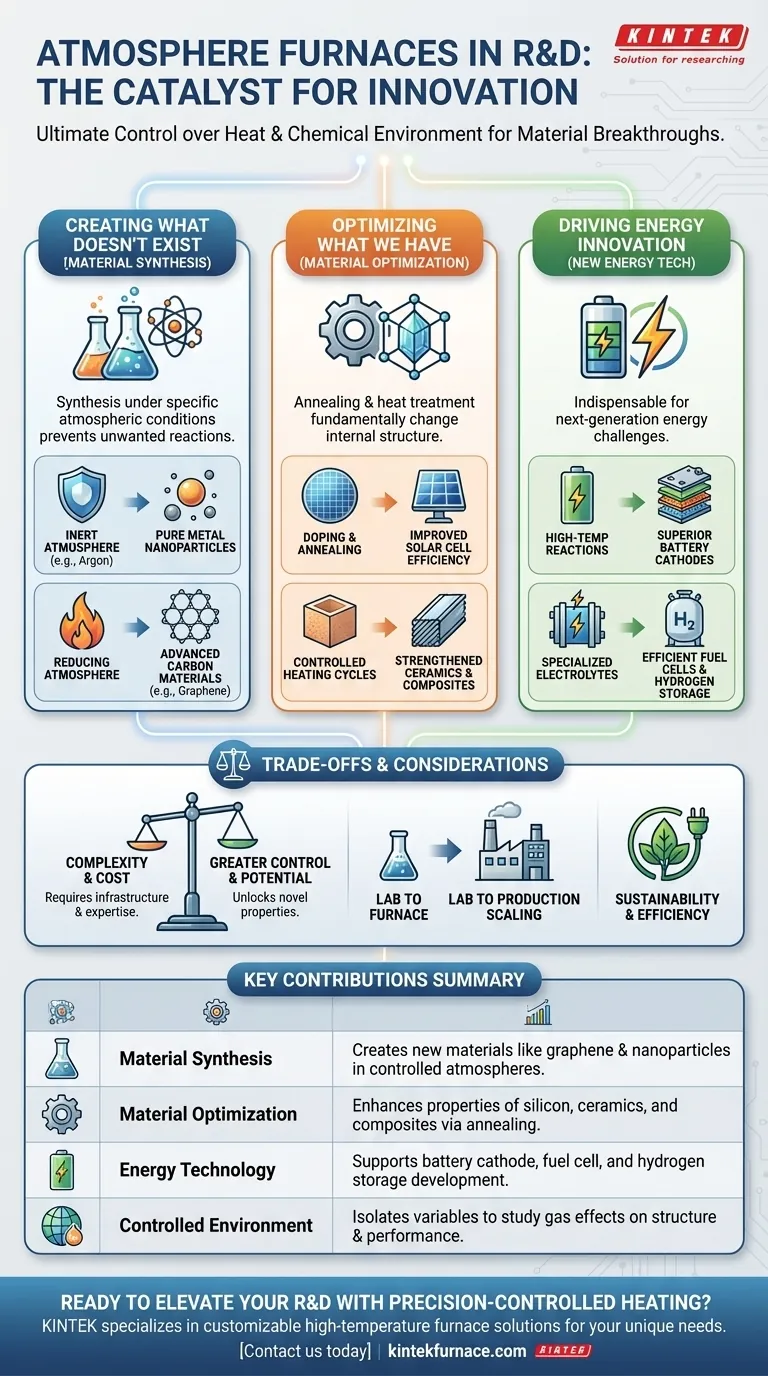

Creating What Doesn't Exist

Many advanced materials can only be synthesized under specific atmospheric conditions that prevent unwanted chemical reactions, like oxidation.

By using an inert atmosphere (like argon), researchers can heat metal oxides to prepare pure metal nanoparticles without them immediately oxidizing.

Likewise, heating carbon-containing compounds in a reducing atmosphere is a key step in creating advanced carbon-based materials like graphene.

Optimizing What We Already Have

The furnace is also essential for improving the performance of existing materials. The process of annealing, or heat treatment, can fundamentally change a material's internal crystal structure.

In solar cell research, for example, furnaces are used for the doping and annealing of silicon wafers. This precise thermal processing improves the material's photoelectric conversion efficiency.

Similarly, high-performance ceramics, glass, and composites are prepared and strengthened through carefully controlled heating and cooling cycles within a specific atmosphere.

Driving Innovation in New Energy

The development of next-generation energy technology is fundamentally a materials science challenge. Atmosphere furnaces are indispensable tools in this field.

Advancing Battery Technology

For lithium-ion batteries, performance is dictated by the chemical composition and structure of the cathode material.

An atmosphere furnace facilitates the high-temperature solid-state reactions needed to produce cathode materials with superior electrochemical performance, leading to longer-lasting and faster-charging batteries.

Enabling Fuel Cells and Hydrogen Storage

Atmosphere furnaces also support the development of next-generation energy systems.

They are used to prepare the specialized electrolyte materials for fuel cells and to synthesize the complex compounds required for safe and efficient hydrogen storage.

Understanding the Trade-offs and Considerations

While powerful, an atmosphere furnace is a specialized piece of equipment. Understanding its context is key to leveraging its full potential.

Control Comes at a Cost

The primary trade-off is complexity. A standard furnace only controls temperature. An atmosphere furnace adds a second, critical variable: gas composition.

This requires gas handling infrastructure, safety protocols, and more sophisticated process control, representing a greater investment in both equipment and operator training.

From R&D to Production

Processes perfected in a small R&D atmosphere furnace must be scaled for industrial production.

While the core principles of temperature and atmosphere remain the same, translating a lab-scale formula to a large-scale manufacturing process presents significant engineering challenges. The R&D phase is a crucial first step in defining the parameters for future production.

Sustainability and Efficiency

Modern furnaces are designed with efficiency in mind, using advanced insulation and heating elements to minimize energy consumption. This aligns with the sustainability goals of research institutions and reduces long-term operational costs, which is a key consideration for any lab.

Making the Right Decision for Your Research

Ultimately, the need for an atmosphere furnace is dictated by your research goals. Its purpose is to provide control over the chemical reactions that occur at high temperatures.

- If your primary focus is novel material synthesis: This tool is essential for creating materials with specific, non-oxidized structures, such as nanoparticles, composites, or 2D materials.

- If your primary focus is optimizing material properties: It allows you to systematically fine-tune characteristics like conductivity, strength, or efficiency through controlled annealing and heat treatment.

- If your primary focus is energy technology: It is an indispensable instrument for developing the next generation of battery cathodes, solar cells, and fuel cell components.

By controlling the environment, an atmosphere furnace empowers you to move beyond simple heating and truly engineer materials at a fundamental level.

Summary Table:

| Key Contribution | Description |

|---|---|

| Material Synthesis | Creates new materials like graphene and nanoparticles in inert or reducing atmospheres. |

| Material Optimization | Enhances properties of silicon wafers, ceramics, and composites via annealing and doping. |

| Energy Technology | Supports battery cathode production, fuel cell materials, and hydrogen storage development. |

| Controlled Environment | Isolates variables to study gas effects on material structure and performance. |

Ready to elevate your R&D with precision-controlled heating? KINTEK specializes in advanced high-temperature furnace solutions, including Atmosphere Furnaces, tailored for materials science, energy research, and manufacturing labs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—from Muffle and Tube Furnaces to Rotary, Vacuum, and CVD/PECVD Systems. Contact us today to discuss how our expertise can accelerate your innovations and deliver reliable, efficient results for your projects!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance