At its core, a vacuum annealing furnace improves material performance by conducting heat treatment in a high-vacuum environment. This process prevents surface oxidation and contamination, allowing for pure structural modifications that relieve internal stresses, refine the material's crystal structure, and significantly enhance properties like toughness, ductility, and strength.

The crucial advantage of a vacuum furnace is not the heat itself, but the absence of air. By removing reactive gases like oxygen, the furnace creates an ultra-clean environment where a material's internal structure can be perfected without introducing surface defects or impurities.

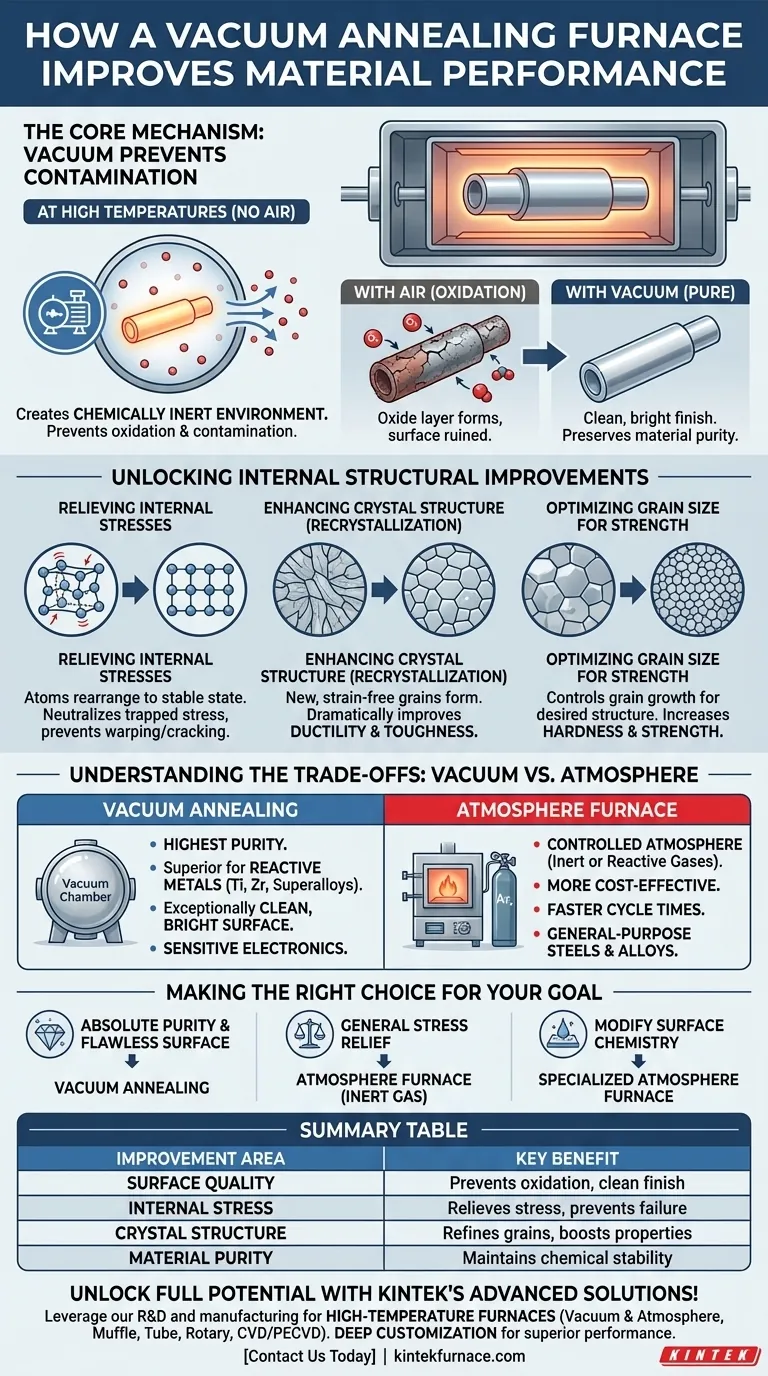

The Core Mechanism: How Vacuum Prevents Contamination

The primary function of the vacuum is to create a chemically inert environment. At the high temperatures required for annealing, materials become highly reactive with gases in the air, but removing those gases circumvents the problem entirely.

Eliminating Oxidation

Without a vacuum, heating a metal part exposes its surface to oxygen, causing an oxide layer (scale) to form. This layer is often brittle, can flake off, and ruins the surface finish. A vacuum furnace pumps out the air, preventing this reaction and resulting in a clean, bright part that often requires no further surface cleaning.

Preserving Material Purity

Many advanced alloys, especially those containing reactive elements like titanium or aluminum, can be compromised by reactions with trace gases. A vacuum environment ensures the material's chemical composition remains stable and pure, which is critical for high-performance applications in aerospace, medical, and electronics.

Unlocking Internal Structural Improvements

Once the pristine environment is established, the controlled heating and cooling cycles of annealing can work on the material's internal structure to reverse the negative effects of prior manufacturing processes.

Relieving Internal Stresses

Processes like machining, welding, or cold-forming introduce significant internal stress into a material's atomic lattice. This trapped stress can lead to dimensional instability, warping, or even cracking over time. Annealing provides the thermal energy needed for atoms to rearrange into a more stable, lower-energy state, effectively neutralizing these internal stresses.

Enhancing the Crystal Structure (Recrystallization)

Deformed materials contain a distorted and strained crystal grain structure. During annealing, the material is heated above its recrystallization temperature, which allows new, strain-free grains to form and grow. This process replaces the damaged microstructure, dramatically improving the material's ductility (ability to deform without fracturing) and toughness.

Optimizing Grain Size for Strength

The final properties of the material are heavily influenced by the size of its crystal grains. By precisely controlling the annealing temperature and cooling rate, a vacuum furnace can manage grain growth to achieve a desired structure. For many applications, a finer grain structure is desirable as it typically increases both hardness and strength.

Understanding the Trade-offs: Vacuum vs. Atmosphere Furnaces

Vacuum annealing is not the only method for controlled heat treatment. Its main alternative is the atmosphere furnace, and choosing between them requires understanding their fundamental differences.

The Role of an Atmosphere Furnace

An atmosphere furnace also prevents unwanted oxidation, but it does so by replacing the air with a controlled atmosphere of specific gases. These can be inert gases like argon or nitrogen to create a neutral environment, or reactive gases for processes that intentionally alter the surface chemistry (like carburizing).

When to Choose Vacuum Annealing

Vacuum provides the highest level of purity. It is the superior choice for:

- Highly reactive metals like titanium, zirconium, and certain superalloys.

- Applications requiring an exceptionally clean, bright surface finish with no possibility of discoloration.

- Sensitive electronic components and semiconductors where even minor contamination can cause failure.

The Case for an Atmosphere Furnace

Atmosphere furnaces are often more cost-effective and can have faster cycle times because they don't require a lengthy pump-down to create a deep vacuum. They are perfectly suitable for general-purpose annealing of many common steels and alloys where absolute purity is not the primary driver.

Making the Right Choice for Your Goal

Selecting the correct heat treatment process depends entirely on your material's requirements and the final properties you need to achieve.

- If your primary focus is absolute purity and a flawless surface: Vacuum annealing is the definitive choice, especially for reactive or high-value materials.

- If your primary focus is general stress relief for common steels: An atmosphere furnace using an inert gas is often a more economical and perfectly sufficient solution.

- If your primary focus is modifying the surface chemistry: A specialized atmosphere furnace is required, as vacuum environments are inherently non-reactive.

Ultimately, understanding the role of the furnace environment empowers you to select the process that will best unlock your material's engineered potential.

Summary Table:

| Improvement Area | Key Benefit |

|---|---|

| Surface Quality | Prevents oxidation and contamination for a clean, bright finish |

| Internal Stress | Relieves stresses from manufacturing to prevent warping and cracking |

| Crystal Structure | Refines grains to boost ductility, toughness, and strength |

| Material Purity | Maintains chemical stability for reactive alloys in high-performance uses |

Unlock the full potential of your materials with KINTEK's advanced vacuum annealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior material performance. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability