The fundamental advantage of a rotary kiln lies in its dynamic action. Unlike a static furnace where material sits idle, a rotary kiln's constant rotation continuously tumbles and mixes the material being processed. This movement ensures every particle is uniformly exposed to the heat source, eliminating the hot and cold spots that plague static systems.

While a static furnace heats material passively from the outside-in, creating significant temperature differences, a rotary kiln actively homogenizes the temperature. Its tumbling motion forces every part of the material to experience a consistent thermal profile, leading to a far more uniform end product.

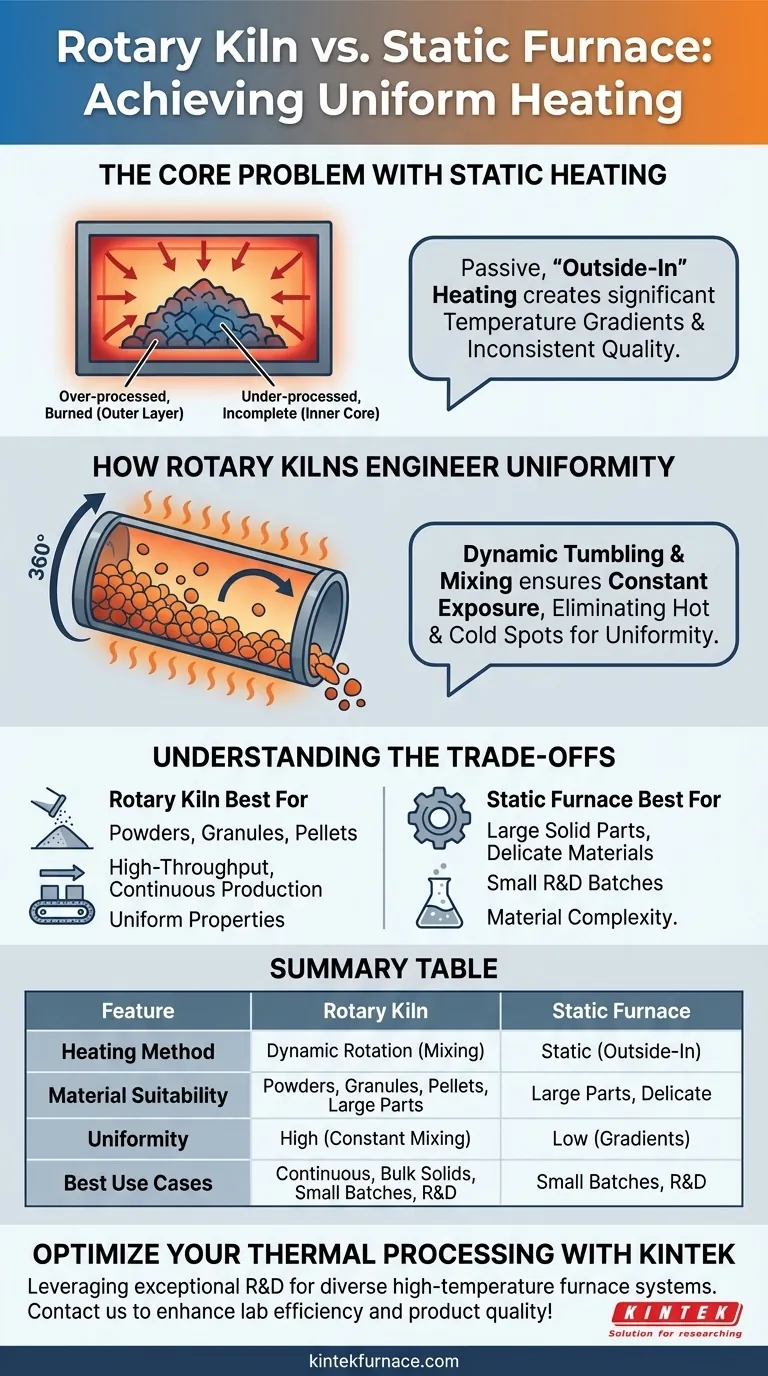

The Core Problem with Static Heating

In a static furnace, the material remains stationary. This simple fact is the source of its primary limitation in achieving uniform heating, especially with piled or bulk materials.

The "Outside-In" Effect

Heat in a static furnace is applied to the outer surfaces of the material bed. The heat must then conduct slowly toward the core.

This creates a significant temperature gradient, where the exterior of the material becomes much hotter than the interior.

Inconsistent Reactions and Quality

This temperature difference leads to inconsistent processing. The outer layers may become over-processed, burned, or have their properties altered undesirably.

Simultaneously, the insulated inner core may be under-processed, resulting in incomplete chemical reactions or insufficient drying. This variability severely impacts final product quality and consistency.

The Challenge of Material Stacking

When materials are stacked or piled, the problem is magnified. The particles at the bottom and center of the pile are heavily insulated by the surrounding material, making it nearly impossible for them to reach the same temperature as the particles on the top surface.

How Rotary Kilns Engineer Uniformity

A rotary kiln solves the static heating problem by introducing controlled, continuous movement. This is achieved through a combination of mechanical design features.

The Power of 360-Degree Rotation

The core mechanism is the rotation of the furnace tube or retort. As the kiln rotates, it lifts the material partway up the side of the cylinder until gravity causes it to tumble back down.

This constant "stirring" action, as described in process literature, ensures that particles from the cool interior are constantly cycled to the hot exterior, and vice versa. This actively breaks up temperature gradients before they can form.

The Role of Inclination (Tilting)

Many rotary kilns are designed to operate at a slight downward angle. This tilt uses gravity to control the flow of material through the furnace from the inlet to the outlet.

This not only ensures continuous processing but also promotes longitudinal mixing, preventing material from accumulating in one section and ensuring a consistent residence time within the heating zone.

Precise and Consistent Heat Application

The uniform mixing action of a rotary kiln is often paired with highly controllable electric heating elements arranged along the length of the furnace.

This combination allows for a very stable and precise thermal environment. The rotation guarantees the material is evenly exposed to this stable heat, resulting in an exceptionally uniform process.

Understanding the Trade-offs

While superior for uniform heating of bulk solids, a rotary kiln is not a universal solution. Its advantages come with specific limitations that make static furnaces a better choice in certain scenarios.

Material Suitability

The tumbling action that is so beneficial for powders and granules can be destructive to other materials.

Large, single components, delicate structures, or materials that could be damaged by abrasion are not suitable for a rotary kiln. For these applications, a static furnace is the necessary choice.

Mechanical Complexity and Maintenance

A rotary kiln is a more complex machine than a static furnace. It involves motors, drive systems, and, critically, high-temperature rotating seals.

These components require a more rigorous maintenance schedule to ensure reliable, long-term operation compared to the relative simplicity of a static box furnace.

Batch Size and Flexibility

Static furnaces are often more practical for very small, distinct R&D batches or when processing many different types of materials that require different vessel shapes. Rotary kilns are optimized for continuous or large-batch processing of a specific type of free-flowing material.

Making the Right Choice for Your Process

The decision between a rotary kiln and a static furnace depends entirely on your material and your processing goals.

- If your primary focus is processing powders, granules, or pellets: The rotary kiln is the superior choice for achieving consistent quality and uniform chemical or physical properties.

- If your primary focus is treating large, solid parts or delicate materials: A static furnace is required to heat the material without causing mechanical damage from tumbling.

- If your primary focus is high-throughput, continuous production: The design of a tilted rotary kiln is inherently built for efficient, continuous material flow.

Understanding the fundamental difference between static and dynamic heating empowers you to select the precise tool for your thermal processing goals.

Summary Table:

| Feature | Rotary Kiln | Static Furnace |

|---|---|---|

| Heating Method | Dynamic rotation for uniform exposure | Static, outside-in heating |

| Material Suitability | Powders, granules, pellets | Large solid parts, delicate materials |

| Uniformity | High, due to constant mixing | Low, prone to temperature gradients |

| Best Use Cases | Continuous processing, bulk solids | Small batches, R&D, non-abrasive materials |

Optimize your thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're processing powders for uniform heating or handling delicate materials, KINTEK has the right furnace for you. Contact us today to discuss how we can enhance your lab's efficiency and product quality!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions