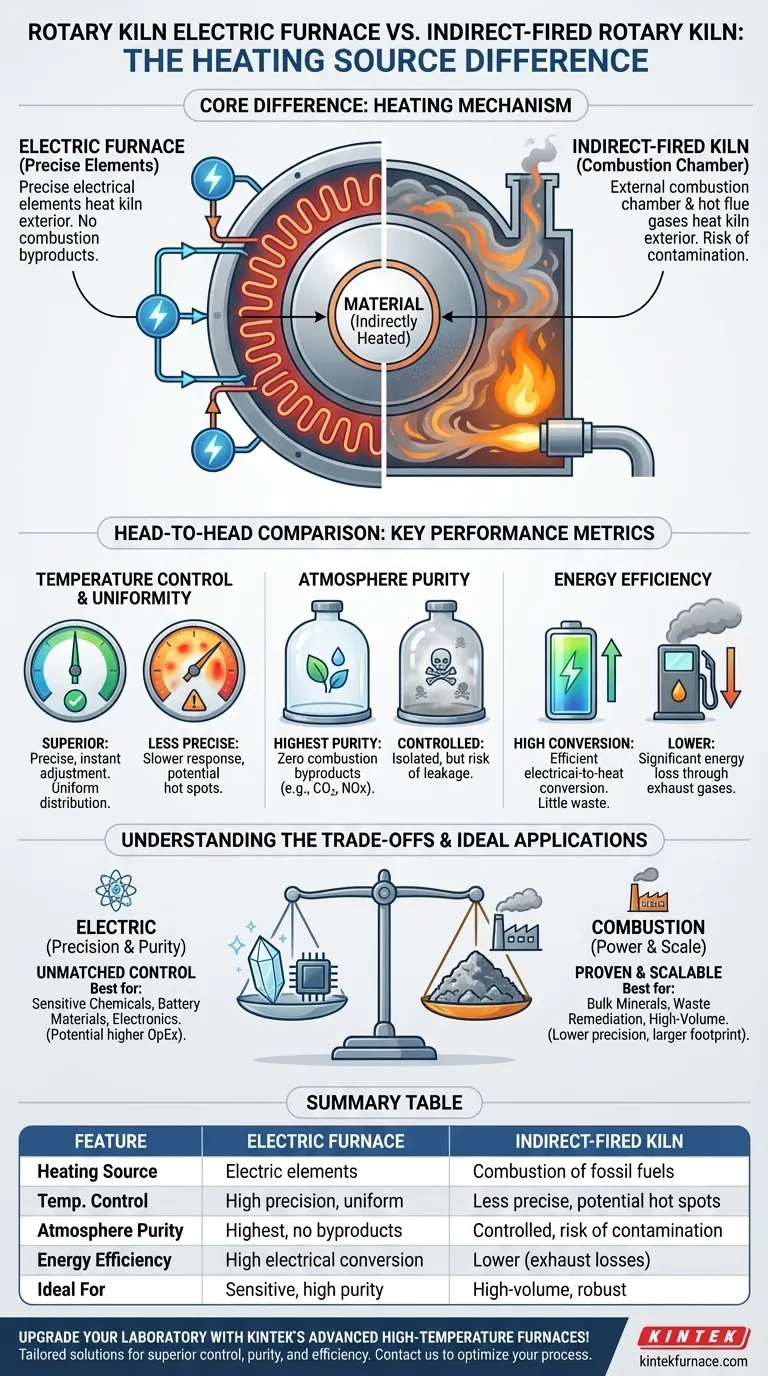

In essence, the difference is the heat source. A rotary kiln electric furnace uses precise electrical elements to heat the kiln's exterior, while a traditional indirect-fired kiln uses an external combustion chamber and hot flue gases. This fundamental distinction directly impacts temperature control, atmosphere purity, and operational efficiency.

The decision between an electric furnace and a combustion-fired kiln is a strategic choice. You are trading the absolute precision and purity of electric heat against the potential cost-effectiveness and raw power of fossil fuel combustion for large-scale applications.

Understanding the Core Difference: The Heating Mechanism

Both designs fall under the category of indirect-fired kilns, meaning the material inside the rotating drum is heated through the kiln wall rather than by direct contact with a flame or hot gas. The key distinction is how that wall is heated.

The Indirect-Fired Rotary Kiln (Combustion-Based)

A traditional indirect-fired kiln, often called a calciner, is heated externally by burning a fuel like natural gas or oil in a separate combustion chamber.

The hot flue gases from this combustion are passed through a sealed space around the rotating kiln shell. The heat transfers from the gas, through the shell, and into the material being processed.

Crucially, the material inside is isolated from the products of combustion, which allows for a controlled atmosphere.

The Rotary Kiln Electric Furnace

The rotary kiln electric furnace is a modern evolution of the indirect-fired design. Instead of a combustion chamber, it uses electric heating elements.

These elements, often made of high-resistance materials, are arranged around the outside of the kiln shell. They generate intense, uniform heat when electricity is passed through them.

This design completely eliminates the need for fossil fuels, combustion chambers, and flue gas handling systems.

A Head-to-Head Comparison: Key Performance Metrics

The choice of heating method creates significant differences in performance, control, and efficiency.

Temperature Control and Uniformity

An electric furnace offers vastly superior temperature control. The energy input from electric elements can be adjusted instantly and with high precision, allowing for exact temperature profiles.

This also leads to more uniform heat distribution around the kiln's circumference, ensuring every particle of material experiences a consistent temperature. Combustion systems have inherent hot spots and slower response times.

Atmosphere Control

While both kiln types isolate the material from the heating source, the electric furnace provides the highest possible atmosphere purity.

There is zero risk of combustion byproducts (like CO₂, H₂O, or NOx) leaking into the process chamber. This is critical for sensitive materials where even trace contamination is unacceptable.

Energy Efficiency

Electric furnaces are highly efficient at converting electrical energy into usable heat. There is very little waste heat compared to a combustion system, which loses significant energy through exhaust stacks.

However, the overall cost-effectiveness depends heavily on the relative price of electricity versus fossil fuels in your region.

Understanding the Trade-offs

Choosing the right technology requires acknowledging the inherent trade-offs of each heating method.

The Precision of Electric Heat

The primary advantage of an electric furnace is its unmatched control. This precision is essential for producing high-value, sensitive materials with repeatable quality.

The trade-off can be higher operational expenditure (OpEx) if local electricity prices are high. The initial capital cost (CapEx) can also be significant, though it avoids the complexity of fuel and exhaust infrastructure.

The Power of Combustion Heat

Combustion-based indirect kilns are proven, robust systems that can be built to enormous scales and powered by a variety of relatively inexpensive fossil fuels.

Their disadvantage is a lack of precision. They are slower to heat up and cool down, and achieving a perfectly uniform temperature profile is more challenging. They also carry a larger environmental footprint and require more complex support equipment.

Structural and Maintenance Considerations

The core components—the shell, refractory lining, support tyres, and drive gear—are similar in both systems.

The key difference lies in maintaining the heating system. An electric furnace requires managing heating elements and electrical controls, while a combustion system requires maintaining burners, fuel lines, and flue gas ducting.

Making the Right Choice for Your Process

Your decision should be driven entirely by the requirements of your material and your operational priorities.

- If your primary focus is material purity and precise temperature profiles: The rotary kiln electric furnace is the definitive choice for applications in specialty chemicals, battery materials, or electronics.

- If your primary focus is high-volume processing of robust materials: A traditional combustion-based indirect-fired kiln is often the more pragmatic and cost-effective solution for bulk minerals or waste remediation.

- If your primary focus is operational cost: You must perform a detailed total cost of ownership analysis, comparing local electricity rates against available fossil fuel prices for your required thermal output.

By understanding the fundamental impact of the heating method, you can confidently select the technology that best serves your process goals.

Summary Table:

| Feature | Rotary Kiln Electric Furnace | Indirect-Fired Rotary Kiln |

|---|---|---|

| Heating Source | Electric elements | Combustion of fossil fuels |

| Temperature Control | High precision, uniform heating | Less precise, potential hot spots |

| Atmosphere Purity | Highest, no combustion byproducts | Controlled, but risk of contamination |

| Energy Efficiency | High electrical conversion | Lower due to exhaust losses |

| Operational Cost | Depends on electricity prices | Depends on fossil fuel prices |

| Ideal For | Sensitive materials, high purity | High-volume, robust materials |

Upgrade Your Laboratory with KINTEK's Advanced High-Temperature Furnaces!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior temperature control, atmosphere purity, and efficiency.

Contact us today to discuss how our tailored furnace solutions can optimize your material processing—Get in touch now!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What types of physical and chemical transformations occur in a rotary kiln? Master Material Processing for Superior Results

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How do vibrational feeder specifications impact rotary kiln efficiency? Optimize Your Lab's Material Flow & Stability

- What supporting equipment is needed for a rotary kiln system? Essential Components for Efficient Thermal Processing