At its core, a retort furnace is fundamentally different from other furnaces because of its sealed inner chamber, known as the retort. While other furnaces focus primarily on achieving a specific temperature, a retort furnace's defining purpose is to create and maintain a highly controlled atmosphere around the material being processed. This makes it indispensable for heat treatments where exposure to air or other contaminants would ruin the final product.

The critical distinction is not how a retort furnace generates heat, but the controlled environment it creates. You choose a retort furnace when the atmosphere during heating is just as important as the temperature itself, a requirement for processes like bright annealing, carburizing, or brazing.

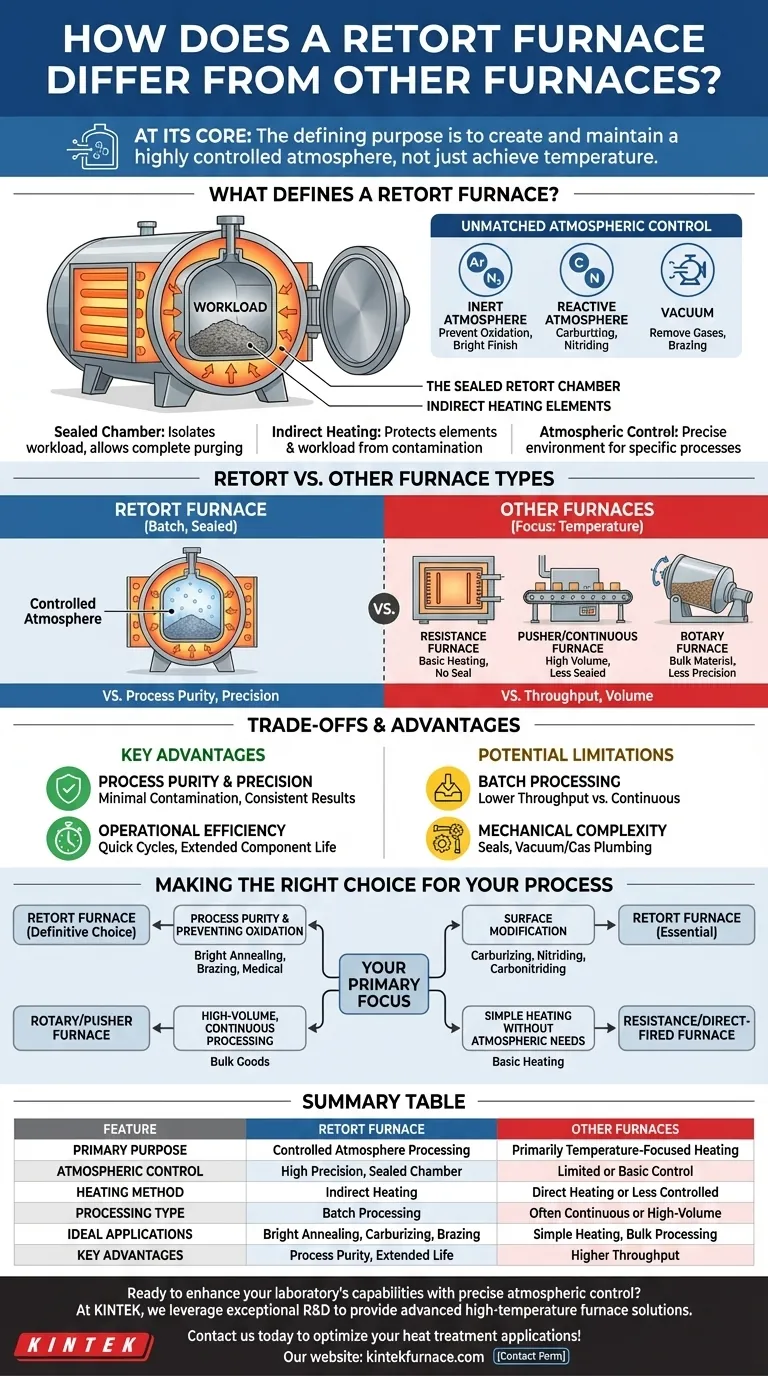

What Defines a Retort Furnace?

The unique capabilities of a retort furnace stem from its specialized design, which separates the workload from the heating elements and the outside environment.

The Sealed Retort Chamber

The "retort" is a container, typically made of metal alloy, that holds the material being heat-treated. This container is sealed shut to create an isolated environment.

This design allows for the complete purging of ambient air (oxygen and nitrogen) and the introduction of specific, controlled gas atmospheres.

Indirect Heating Principle

In most retort furnaces, the heating elements (either electric or gas-fired) are located outside the sealed retort.

Heat transfers through the walls of the retort to the material inside. This indirect heating protects the heating elements from potentially corrosive process atmospheres and prevents contamination of the workload.

Unmatched Atmospheric Control

The primary reason to use a retort furnace is for precise atmospheric control. This is critical for processes that require:

- Inert Atmospheres: Using gases like argon or nitrogen to prevent oxidation, resulting in a clean, "bright" surface finish.

- Reactive Atmospheres: Introducing gases that intentionally react with the material's surface, such as in carburizing (adding carbon) or nitriding (adding nitrogen).

- Vacuum: Pumping all gases out of the retort to heat materials in a near-perfect vacuum, which is essential for certain alloys and brazing applications.

How Retort Furnaces Compare to Other Types

Understanding the specific purpose of a retort furnace becomes clearer when compared to other common industrial furnaces.

Retort vs. Resistance Furnaces

A standard resistance furnace simply uses electric elements to heat a chamber. Its primary goal is temperature, not atmosphere. While some may have rudimentary seals, they cannot achieve the purity or control of a sealed retort system.

Retort vs. Pusher/Continuous Furnaces

Pusher furnaces are designed for high-volume, continuous processing where parts are pushed through different temperature zones. While some may have controlled atmospheres, they are generally less perfectly sealed than a batch retort furnace due to the need for entry and exit points.

Retort vs. Rotary Furnaces

A rotary furnace tumbles bulk materials inside a rotating drum for uniform, continuous heating. It excels at processing large volumes of powders or small parts but offers less precise atmospheric control than a sealed batch retort.

Understanding the Trade-offs and Advantages

Choosing a retort furnace involves weighing its unique benefits against its operational model.

Key Advantage: Process Purity and Precision

The sealed retort guarantees minimal gas consumption because there are no leaks. It also provides the highest level of protection against contamination, ensuring consistent, high-quality results.

Key Advantage: Operational Efficiency

Modern retort furnaces often feature quick heating and cooling cycles due to efficient heat transfer. By protecting the furnace insulation and heating elements from the process atmosphere, they also extend the life of these critical components.

Potential Limitation: Batch Processing

Most retort furnace designs are for batch processing, where one load is completed at a time. This may result in lower throughput compared to a fully continuous furnace like a pusher or rotary type.

Potential Limitation: Mechanical Complexity

The need for a perfectly sealed retort, along with the associated plumbing for vacuum and process gases, adds mechanical complexity compared to a simple air-fired box furnace.

Making the Right Choice for Your Process

Your specific heat-treating goal is the single most important factor in selecting the right furnace technology.

- If your primary focus is process purity and preventing oxidation: A retort furnace is the definitive choice for bright annealing, brazing, or medical-grade components.

- If your primary focus is surface modification: A retort furnace is essential for reactive processes like carburizing, nitriding, or carbonitriding.

- If your primary focus is high-volume, continuous processing of bulk goods: A rotary or pusher furnace may offer better throughput for your application.

- If your primary focus is simple heating without atmospheric needs: A basic resistance or direct-fired furnace is a more direct and cost-effective solution.

Ultimately, selecting a retort furnace is a decision to prioritize precise environmental control over all other factors.

Summary Table:

| Feature | Retort Furnace | Other Furnaces (e.g., Resistance, Pusher, Rotary) |

|---|---|---|

| Primary Purpose | Controlled atmosphere processing (e.g., inert, reactive gases, vacuum) | Primarily temperature-focused heating |

| Atmospheric Control | High precision with sealed retort chamber | Limited or basic control, often less sealed |

| Heating Method | Indirect heating (elements outside retort) | Direct heating or less controlled methods |

| Processing Type | Batch processing | Often continuous or high-volume (e.g., pusher, rotary) |

| Ideal Applications | Bright annealing, carburizing, brazing, medical components | Simple heating, bulk material processing |

| Key Advantages | Process purity, minimal contamination, extended component life | Higher throughput for non-critical atmospheres |

Ready to enhance your laboratory's capabilities with precise atmospheric control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to meet unique experimental requirements. Whether you're working on bright annealing, carburizing, or other specialized processes, our retort furnaces ensure superior performance and reliability. Contact us today to discuss how we can optimize your heat treatment applications!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality