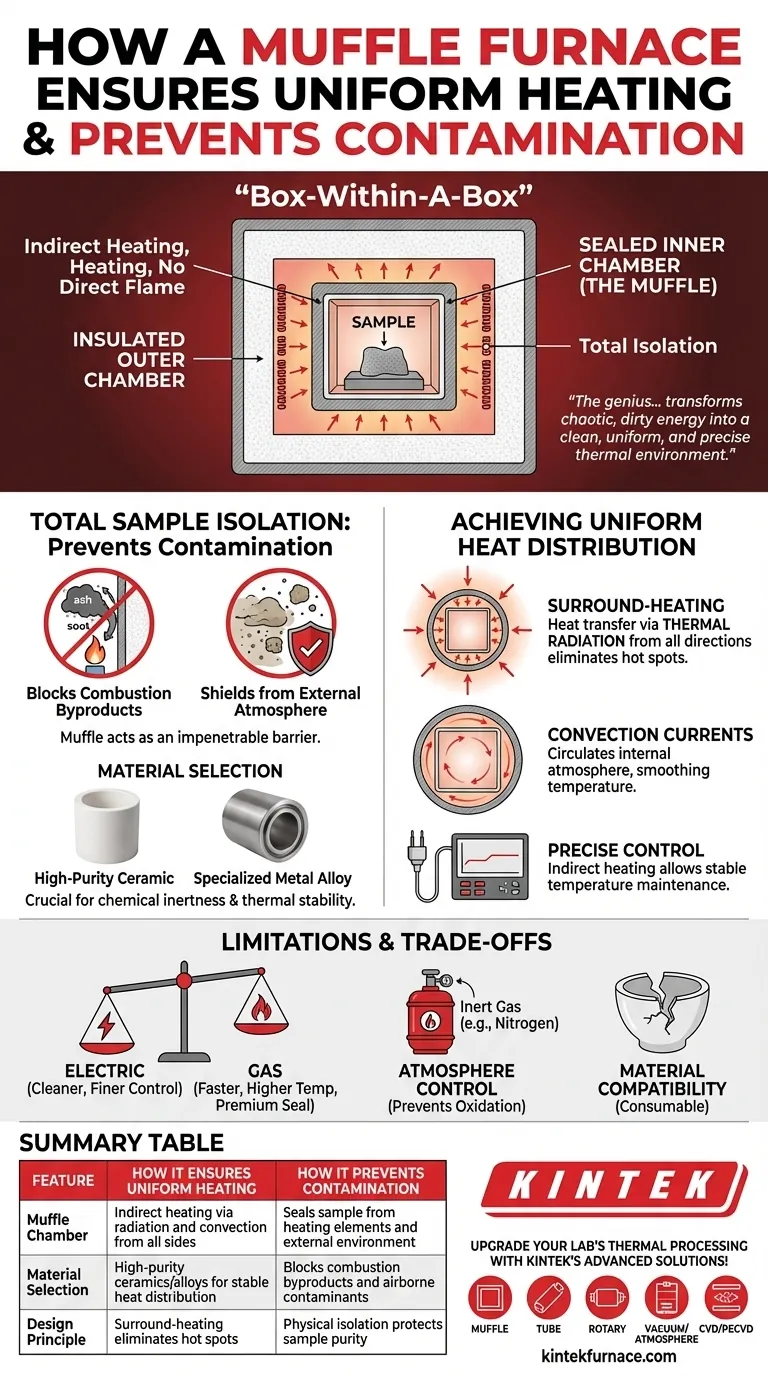

At its core, a muffle furnace achieves uniform heating and prevents contamination through its fundamental design: a highly insulated outer chamber heats a sealed inner chamber—the "muffle"—where the sample is placed. This design physically isolates the sample from both the heating source and the external environment, ensuring heat is applied indirectly and evenly while blocking all potential contaminants.

The genius of the muffle furnace is not in how it generates heat, but in how it isolates the sample. By creating a controlled "box-within-a-box," it transforms the chaotic, dirty energy of a direct heat source into a clean, uniform, and precise thermal environment.

The Core Principle: Total Sample Isolation

The entire function of a muffle furnace revolves around the concept of the muffle itself. Understanding this chamber is key to understanding the furnace's effectiveness.

What is a "Muffle"?

Think of the muffle as a high-temperature safe deposit box for your sample. It is a sealed chamber, typically made of high-purity ceramic or a specialized metal alloy, that sits inside the main furnace.

The heating elements or gas flames heat the outside of this muffle, not the sample directly.

How Isolation Prevents Contamination

By separating the sample from the heat source, the muffle acts as an impenetrable barrier. This is critical for two reasons.

First, it blocks combustion byproducts. In gas-fired furnaces, this prevents ash, soot, and reactive gases from ever touching the sample. In electric furnaces, it protects the sample from any potential off-gassing from the heating elements themselves.

Second, the enclosed design shields the sample from the external atmosphere. This prevents airborne dust, moisture, or other environmental contaminants from compromising the sample's purity, which is crucial for sensitive chemical analysis or materials testing.

The Right Materials for the Job

The choice of muffle material is critical. High-purity ceramics are often used for their excellent thermal stability and chemical inertness.

For applications involving particularly aggressive vapors or gases, muffles made from high-temperature metal alloys are used to provide superior resistance to chemical attack and degradation.

Achieving Uniform Heat Distribution

Isolating the sample is only half the battle. The furnace must also deliver heat evenly to the entire sample to ensure consistent and repeatable results.

The Power of Indirect Heating

Because the sample is not exposed to a direct flame or a single hot element, "hot spots" are eliminated. The entire muffle chamber is heated, and it is the chamber itself that heats the sample.

Radiation and Convection in Harmony

Heat is transferred to the sample primarily through thermal radiation. The hot inner walls of the muffle radiate heat energy inward from all directions—top, bottom, and all sides. This "surround-heating" effect is the primary mechanism for ensuring temperature uniformity.

Additionally, gentle convection currents within the sealed muffle help to circulate the internal atmosphere (whether it's air or a controlled gas), further distributing heat and smoothing out any minor temperature differences.

The Foundation for Precise Control

This indirect, uniform heating method makes it much easier for the furnace's control system (the thermocouple and PID controller) to maintain a stable and precise temperature. There are no sudden fluctuations from a flaring flame or a cycling heating element to contend with.

Understanding the Limitations and Trade-offs

While highly effective, the design is not without its considerations. Objectively understanding its trade-offs is crucial for proper application.

Heating Method Matters

Most modern lab furnaces use electric resistance heating elements. This is inherently cleaner and offers finer control than gas.

Gas-fired furnaces can achieve higher temperatures and heat more rapidly but place an absolute premium on the muffle's seal integrity. Any breach would immediately lead to sample contamination.

Atmosphere is Not Automatically Controlled

A standard muffle furnace protects from external contaminants. However, the air sealed inside the muffle will still cause oxidation at high temperatures.

If you need to prevent oxidation or carbonization, you need a furnace with atmosphere control. These models include ports to purge the air from the muffle and replace it with an inert gas like nitrogen or argon.

Material Compatibility

The muffle is a consumable component over the long term, especially under aggressive conditions. Certain chemical vapors can slowly degrade the ceramic or alloy, and extreme temperatures can cause stress. You must ensure your process is compatible with the muffle material.

How to Apply This to Your Process

Your specific goal will determine which aspect of the furnace's design is most critical to your work.

- If your primary focus is analytical purity: Pay closest attention to the muffle material and ensure the furnace door provides a perfect seal to prevent any atmospheric leaks.

- If your primary focus is consistent material processing: The uniform radiative heating is your greatest asset, as it ensures every part of your sample or batch sees the same thermal profile.

- If your primary focus is preventing oxidation: You must use a furnace specifically designed with gas ports for atmosphere control to purge the chamber with an inert gas.

Understanding these principles allows you to move beyond simply operating the equipment and begin truly controlling your thermal process for reliable and accurate results.

Summary Table:

| Feature | How It Ensures Uniform Heating | How It Prevents Contamination |

|---|---|---|

| Muffle Chamber | Indirect heating via radiation and convection from all sides | Seals sample from heating elements and external environment |

| Material Selection | High-purity ceramics/alloys for stable heat distribution | Blocks combustion byproducts and airborne contaminants |

| Design Principle | Surround-heating eliminates hot spots | Physical isolation protects sample purity |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise, contamination-free heating. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals