In a direct comparison, low vacuum furnaces offer significantly faster process speeds and cycle times than their high vacuum counterparts. This speed advantage is a direct result of the less stringent vacuum levels they are designed to achieve, requiring a simpler and quicker pump-down process.

The choice between a low and high vacuum furnace is not simply about speed. It represents a fundamental trade-off between processing time and cost on one side, and atmospheric purity and maximum temperature on the other.

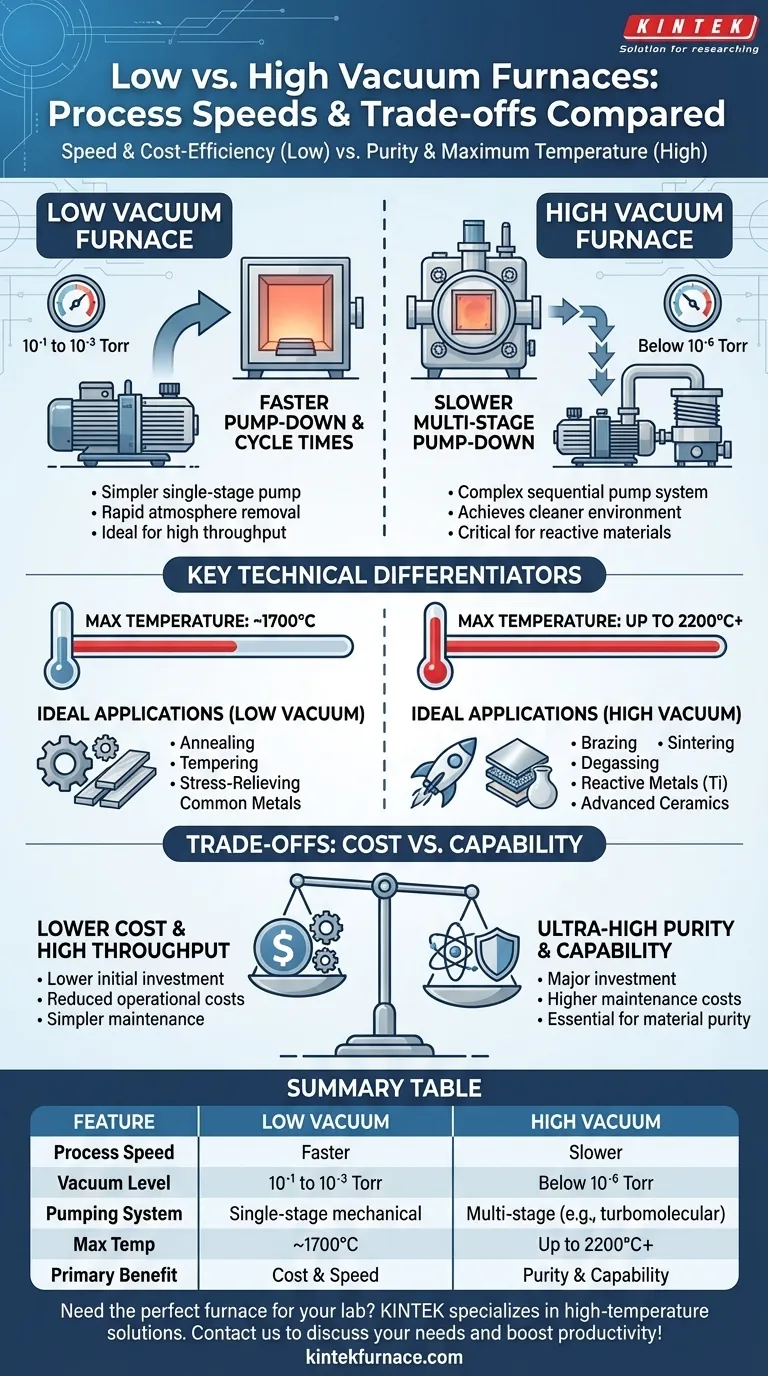

The Core Difference: Pump-Down Time

The primary factor dictating the overall process speed is the time it takes to evacuate the furnace chamber to the target vacuum level, known as "pump-down time."

Why Low Vacuum is Faster

Low vacuum furnaces typically operate in the range of 10⁻¹ to 10⁻³ Torr. Reaching this pressure requires only a single-stage mechanical pump, such as a rotary vane pump.

This simpler system removes the bulk of the atmosphere quickly, resulting in rapid pump-down and significantly shorter overall cycle times.

Why High Vacuum is Slower

High vacuum furnaces operate at much lower pressures, often below 10⁻⁶ Torr. Achieving this level of vacuum is a more complex, multi-stage process.

First, a mechanical pump (like in a low vacuum system) acts as a "roughing pump." Then, a secondary pump—such as a turbomolecular or diffusion pump—takes over to remove the remaining molecules. This sequential process is inherently slower and more time-consuming.

Beyond Speed: Key Technical Differentiators

While speed is a major factor, the underlying technology defines the capabilities and suitable applications for each furnace type.

Pumping Systems and Vacuum Level

As noted, a low vacuum furnace uses a single mechanical pump. This is effective for general heat-treating applications where some residual atmosphere is acceptable.

A high vacuum furnace uses a multi-stage system to create a much cleaner environment, which is critical for preventing oxidation and contamination with sensitive or reactive materials.

Maximum Operating Temperature

The furnace's vacuum capability directly impacts its temperature limits.

Low vacuum furnaces generally have a maximum operating temperature of around 1700°C.

High vacuum furnaces, with their superior atmospheric control and construction, can often reach much higher temperatures, up to 2200°C or more, enabling processes for advanced materials.

Understanding the Trade-offs: Cost vs. Capability

The decision to prioritize speed (low vacuum) or purity (high vacuum) comes with significant financial and operational implications.

Initial Investment and Operational Costs

Low vacuum furnaces are significantly less expensive to purchase and operate. Their simpler design, with fewer complex components, leads to lower initial capital outlay and reduced maintenance requirements.

High vacuum systems represent a major investment. The sophisticated multi-stage pumps, advanced controls, and robust chamber construction result in higher acquisition and ongoing maintenance costs.

Process Suitability

A low vacuum furnace is ideal for processes like annealing, tempering, and stress-relieving common metals where speed and throughput are primary concerns.

A high vacuum furnace is essential for processes like brazing, sintering, degassing, and heat-treating reactive metals (like titanium) or advanced ceramics, where preventing any chemical reaction with residual atmospheric gases is paramount.

Making the Right Choice for Your Application

Selecting the correct furnace requires a clear understanding of your process requirements, not just a desire for speed.

- If your primary focus is high throughput and cost-efficiency: A low vacuum furnace is the superior choice for applications where ultra-high purity is not a critical factor.

- If your primary focus is material purity and high-temperature processing: A high vacuum furnace is non-negotiable, as its clean environment is essential for achieving the required material properties.

Understanding this balance between speed, cost, and technical necessity is the key to selecting the right vacuum furnace for your specific goals.

Summary Table:

| Feature | Low Vacuum Furnace | High Vacuum Furnace |

|---|---|---|

| Process Speed | Faster | Slower |

| Vacuum Level | 10⁻¹ to 10⁻³ Torr | Below 10⁻⁶ Torr |

| Pumping System | Single-stage mechanical pump | Multi-stage system (e.g., turbomolecular pump) |

| Max Temperature | ~1700°C | Up to 2200°C or more |

| Ideal Applications | Annealing, tempering, stress-relieving | Brazing, sintering, reactive metal processing |

| Cost | Lower initial and operational costs | Higher initial and maintenance costs |

Need the perfect furnace for your lab? KINTEK specializes in high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With deep customization and robust R&D, we ensure your unique experimental needs are met efficiently. Contact us today to discuss how our advanced furnaces can boost your productivity and precision!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety