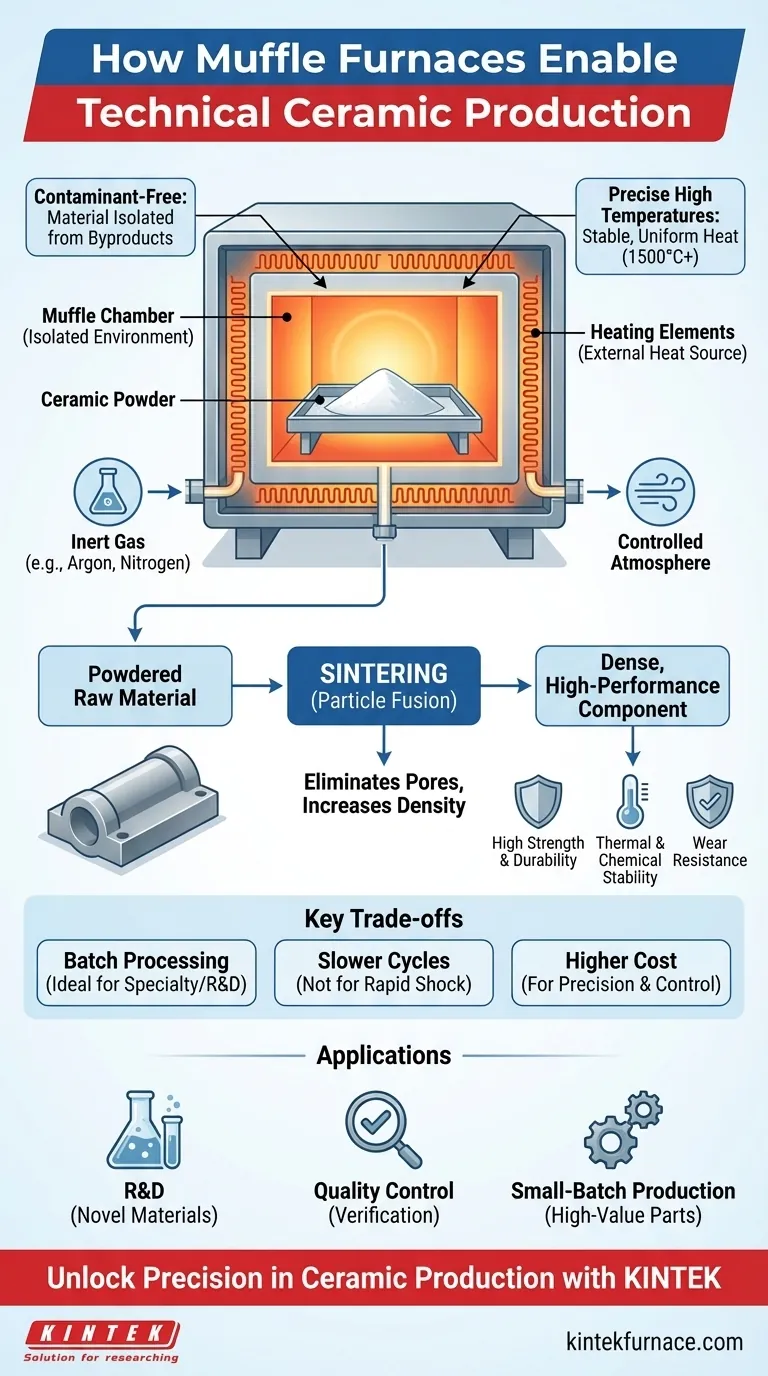

Muffle furnaces are fundamental to producing technical ceramics because they create the exact high-temperature, controlled, and contaminant-free environments necessary for processes like sintering. This transforms powdered raw materials into dense, high-performance components with exceptional strength and durability.

The critical value of a muffle furnace is not simply reaching high temperatures, but the quality of that heat. By isolating the ceramic from fuel byproducts and enabling precise atmospheric control, it allows for the creation of high-purity materials with specific, repeatable properties that are otherwise impossible to achieve.

The Core Function: Creating the Ideal Thermal Environment

A muffle furnace is more than just a hot box; it is a precision instrument designed to control every variable of the heating process. This control is what makes the production of advanced ceramics possible.

The "Muffle" Principle: Guaranteeing Material Purity

The defining feature of a muffle furnace is its muffle—a separate chamber that contains the material being heated. This chamber isolates the ceramic from the actual heating elements and, crucially, any byproducts of combustion.

This separation is non-negotiable for technical ceramics, where even microscopic impurities can compromise the final material's structural integrity and performance characteristics.

Achieving Precise and Stable High Temperatures

Technical ceramics require firing at extremely high temperatures, often exceeding 1500°C, to achieve proper densification. Muffle furnaces are built for this purpose.

They use thick insulating walls and specialized fiber materials in the door to maintain thermal stability and efficiency. This ensures the temperature inside the chamber is uniform and precisely held for the required duration, leading to consistent results batch after batch.

Enabling Advanced Atmospheric Control

Many advanced ceramics are sensitive to oxygen at high temperatures. Muffle furnaces can be configured to operate with specific atmospheres, such as low-oxygen or completely inert gas environments (e.g., argon or nitrogen).

This capability prevents oxidation and unwanted chemical reactions, preserving the integrity of materials like non-oxide ceramics and certain metallic composites.

From Powder to High-Performance Component

The journey of a technical ceramic involves transforming a carefully formulated powder into a solid, functional part. The muffle furnace is where this critical transformation occurs.

The Sintering Process

The primary process enabled by a muffle furnace is sintering. During sintering, ceramic particles are heated to a point just below their melting temperature.

At this temperature, the particles fuse together, gradually eliminating the pores between them. The result is a dense, solidified, and mechanically strong ceramic component.

Developing Exceptional Properties

The controlled environment of the muffle furnace directly influences the final properties of the ceramic. Precise temperature and atmospheric control allow engineers to achieve:

- High Density: Minimizing porosity for maximum strength.

- Hardness and Wear Resistance: Creating a robust material structure.

- Thermal and Chemical Stability: Ensuring the component can withstand extreme conditions.

A Critical Tool for Research and Quality Control

Beyond production, muffle furnaces are indispensable in research labs for developing new materials and in quality control to verify that finished parts meet stringent specifications. Their ability to replicate precise thermal cycles allows for reliable material analysis and characterization.

Understanding the Key Trade-offs

While essential, muffle furnaces are not a universal solution for all thermal processing needs. Understanding their limitations is key to using them effectively.

Batch Processing vs. Continuous Production

Muffle furnaces are inherently batch processors. They are ideal for producing highly specialized, complex components in smaller quantities or for research and development.

For mass production of simpler ceramic items, a continuous-flow tunnel kiln is often more economically viable.

Heating and Cooling Rates

The thick insulation required to maintain stable high temperatures means that muffle furnaces generally have slower heating and cooling cycles. Processes requiring extremely rapid thermal shock or quenching may demand different types of furnaces.

Cost and Complexity

Features like high-temperature alloys, advanced insulation, and especially atmospheric control systems add to the furnace's cost and operational complexity. The precision they offer comes at a higher price point than simpler kilns.

Making the Right Choice for Your Goal

Selecting the right thermal processing method depends entirely on your specific objective, whether it's creating a new material or manufacturing a proven component.

- If your primary focus is research and development: A muffle furnace with advanced atmospheric control is essential for exploring the properties of novel materials without contamination.

- If your primary focus is quality control and verification: A standard, reliable muffle furnace provides the repeatable, high-temperature environment needed to certify that products meet specifications.

- If your primary focus is specialized, small-batch production: The precision of a muffle furnace makes it the ideal choice for creating high-value technical ceramic components.

Ultimately, the muffle furnace empowers engineers and scientists to execute the delicate process of sintering with unparalleled precision and control.

Summary Table:

| Aspect | Contribution to Technical Ceramics |

|---|---|

| Purity | Isolates materials from contaminants for high-purity ceramics. |

| Temperature Control | Provides stable, uniform heating up to 1500°C+ for sintering. |

| Atmospheric Control | Allows inert gas use to prevent oxidation and ensure integrity. |

| Sintering Process | Fuses ceramic powders into dense, strong components. |

| Applications | Ideal for R&D, quality control, and small-batch production. |

Unlock Precision in Your Ceramic Production with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing new materials or ensuring quality in production, our furnaces deliver the contaminant-free environments and exact temperature control essential for high-performance technical ceramics.

Contact us today to discuss how our tailored solutions can enhance your processes and drive innovation in your lab!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis