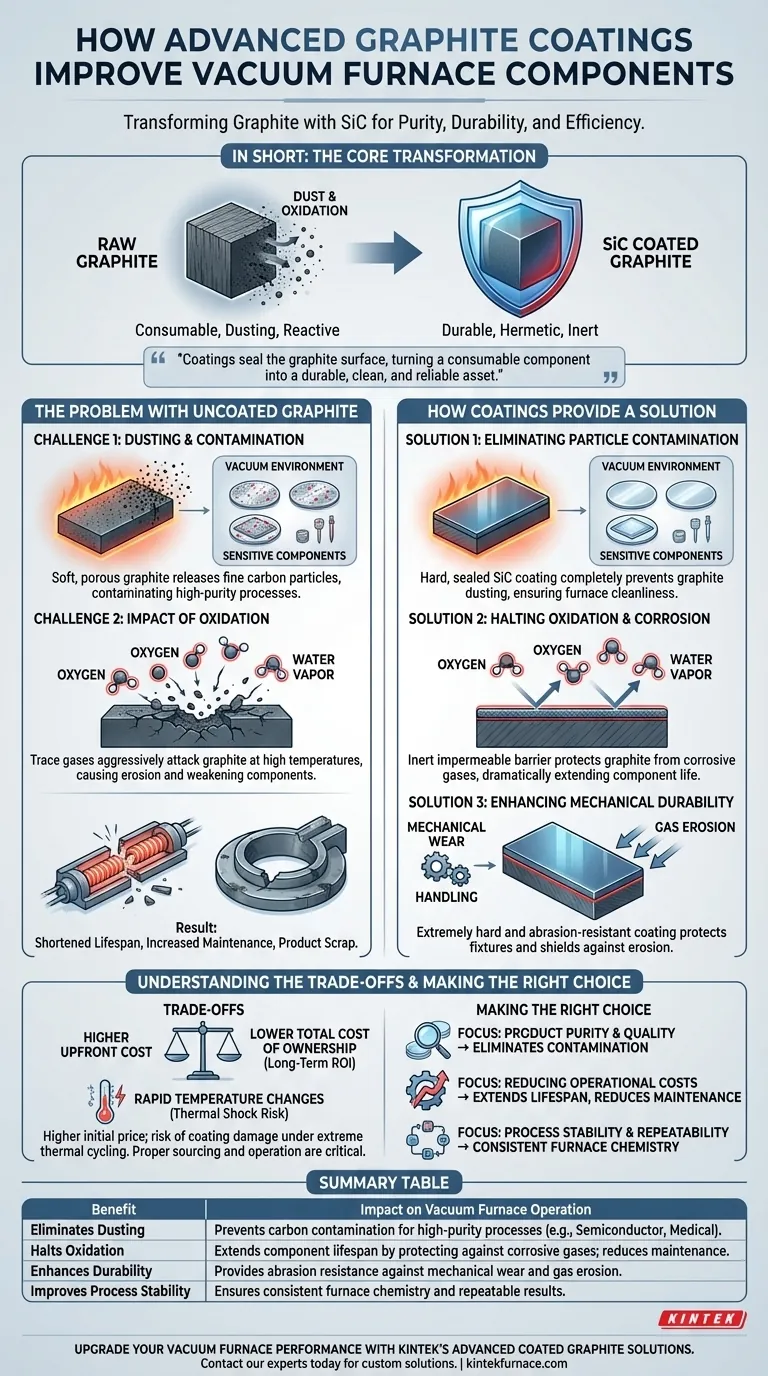

In short, advanced coatings like silicon carbide (SiC) fundamentally transform graphite vacuum furnace components by creating a hermetic, durable shield. This protective layer prevents graphite from shedding particles, oxidizing, and reacting with processed materials, which directly extends component lifespan, improves process purity, and reduces operational costs.

The core issue with raw graphite is not its performance at high temperatures, but its tendency to degrade and release dust, contaminating the vacuum environment. Coatings solve this problem by sealing the graphite surface, turning a consumable component into a durable, clean, and reliable asset.

The Problem with Uncoated Graphite

Graphite is a remarkable material for high-temperature vacuum applications due to its thermal stability and structural integrity. However, its inherent properties present significant operational challenges.

The Challenge of Dusting and Contamination

Uncoated graphite is relatively soft and porous. During heating cycles and under vacuum, it can release fine carbon particles, a phenomenon known as dusting or shedding.

This particulate contamination is a critical failure point in high-purity processes, such as those in the semiconductor, medical implant, and aerospace industries. A single stray particle can ruin an entire batch of sensitive components.

The Impact of Oxidation

Even in a high vacuum, trace amounts of oxygen and water vapor are always present. At the extreme temperatures of a vacuum furnace, these residual gases aggressively attack the graphite surface.

This oxidation causes the graphite to erode, weakening components like heating elements, fixtures, and insulation. The result is a drastically shortened component lifespan and increased maintenance frequency.

How Coatings Provide a Comprehensive Solution

A silicon carbide (SiC) coating is not merely painted on; it is typically formed through a Chemical Vapor Deposition (CVD) process. This creates a dense, non-porous layer that is chemically bonded to the graphite, effectively sealing it from the furnace environment.

Eliminating Particle Contamination

The hard, sealed surface of the SiC coating completely prevents graphite dusting. This is the single most important benefit for applications requiring extreme cleanliness.

By locking the graphite particles in place, the coating ensures that the furnace interior and the products being processed remain free of carbon contamination.

Halting Oxidation and Corrosion

The SiC coating is exceptionally inert and far more resistant to oxidation than graphite. It acts as an impermeable barrier, preventing corrosive gases from reaching and degrading the graphite substrate.

This protection dramatically extends the life of heating elements, racks, and fixtures, even under demanding thermal cycles.

Enhancing Mechanical Durability

Graphite components can be brittle and susceptible to mechanical wear and erosion. A SiC coating is extremely hard and abrasion-resistant.

This added durability protects fixtures from damage during loading and unloading and shields all components from erosion caused by high-velocity gas flows during quenching or backfilling operations.

Understanding the Trade-offs

While the benefits are substantial, adopting coated graphite components requires a clear understanding of the associated considerations.

The Upfront Cost vs. Total Cost of Ownership

Coated components have a higher initial purchase price than their uncoated counterparts. This can be a deterrent for those focused solely on upfront capital expenditure.

However, the true value is revealed when considering the total cost of ownership. The extended lifespan, reduced furnace downtime, lower maintenance labor, and prevention of product scrap often result in a significant long-term return on investment.

Potential for Thermal Shock Damage

While robust, the bond between the coating and the graphite can be stressed by extremely rapid temperature changes. Poorly manufactured coatings or exceptionally harsh thermal cycles can potentially lead to cracking or delamination.

It is critical to source components from reputable manufacturers and operate the furnace within specified ramp rates to ensure coating integrity.

Making the Right Choice for Your Goal

The decision to use coated graphite components should be driven by your specific process requirements and business objectives.

- If your primary focus is product purity and quality: Coated components are essential. The elimination of particle contamination is a non-negotiable advantage for medical, aerospace, and electronics manufacturing.

- If your primary focus is reducing operational costs: Coated components are a strategic investment. The extended lifespan directly translates to less frequent replacement, reduced maintenance, and increased furnace uptime.

- If your primary focus is process stability and repeatability: The inertness of the coating prevents unwanted side-reactions, ensuring that the furnace chemistry remains consistent from batch to batch.

Ultimately, adopting advanced coatings empowers you to move beyond managing graphite's limitations and instead leverage its full potential in a clean, reliable, and cost-effective manner.

Summary Table:

| Benefit | Impact on Vacuum Furnace Operation |

|---|---|

| Eliminates Dusting | Prevents carbon contamination, crucial for high-purity processes in semiconductor and medical industries. |

| Halts Oxidation | Extends component lifespan by protecting against corrosive gases, reducing maintenance frequency. |

| Enhances Durability | Provides abrasion resistance, protecting against mechanical wear during loading/unloading and gas quenching. |

| Improves Process Stability | Ensures consistent furnace chemistry and repeatable results by preventing unwanted reactions. |

Upgrade your vacuum furnace performance with KINTEK's advanced coated graphite solutions.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace components. Our silicon carbide-coated graphite products, including heating elements, fixtures, and insulation, are designed to eliminate contamination, extend service life, and reduce your total cost of ownership. Our strong deep customization capability ensures we can precisely meet your unique process requirements.

Ready to achieve superior purity and durability? Contact our experts today to discuss how our coated components can optimize your vacuum furnace operations.

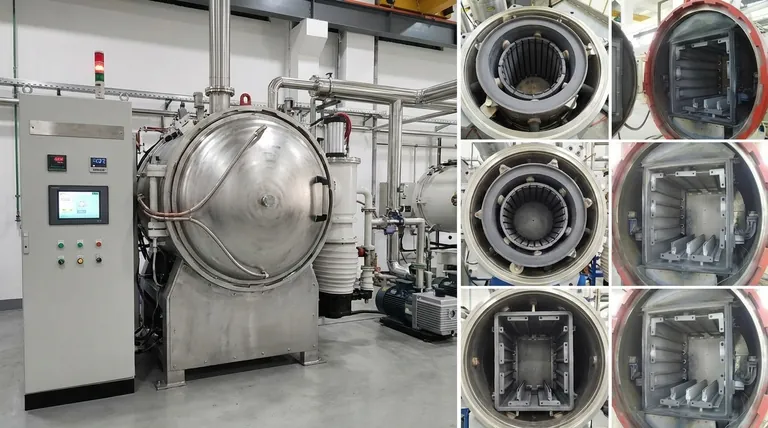

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability