At its core, a tubular furnace is used in production for high-temperature thermal processes that demand a strictly controlled environment. Its primary applications include modifying material properties through heat treatment—like annealing and sintering—and synthesizing advanced materials, such as the thin films used in semiconductors.

The decision to use a tubular furnace in production is driven by the need for atmospheric control. Its unique value is not just heating a material, but heating it within a precisely managed vacuum or a specific gas environment to achieve results that are impossible in open air.

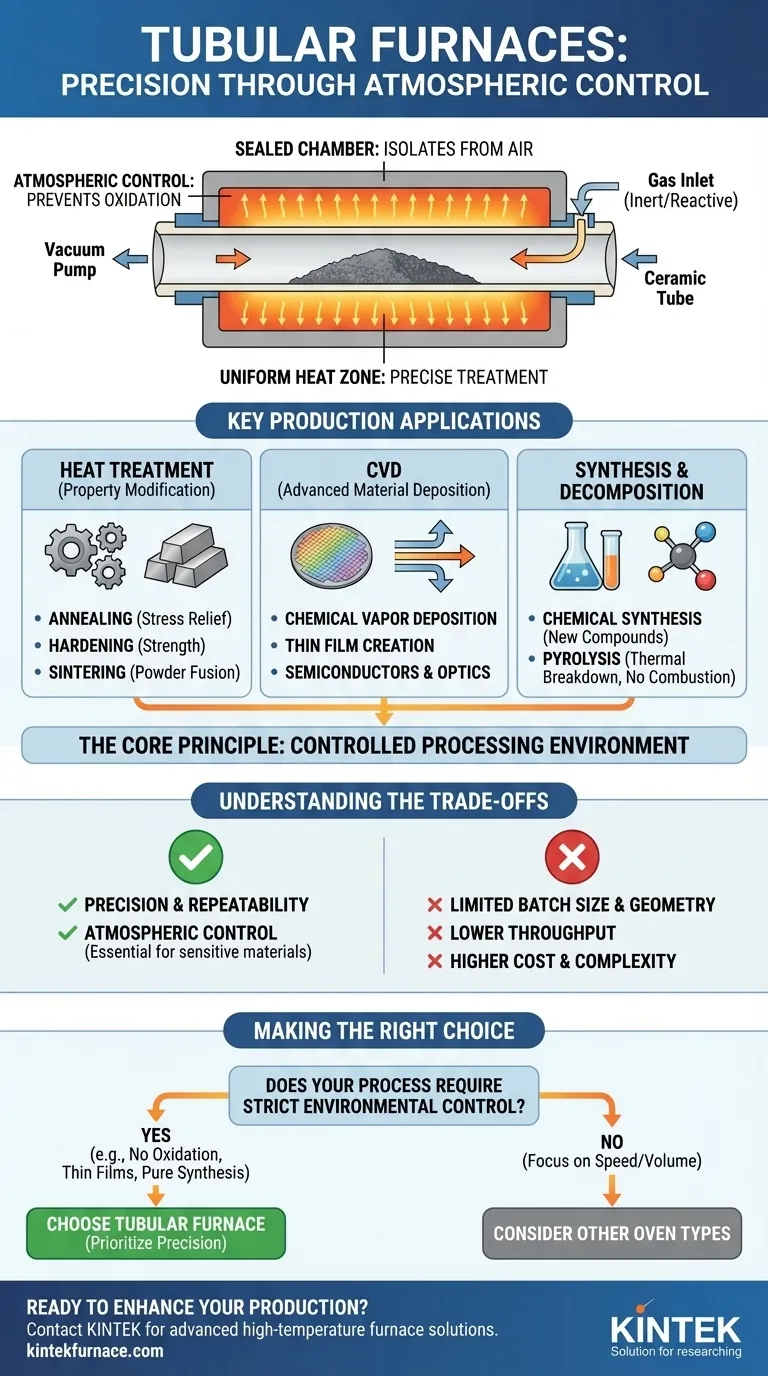

The Core Principle: A Controlled Processing Environment

The defining feature of a tubular furnace is its cylindrical chamber. This design is not arbitrary; it is fundamental to its function of creating a highly isolated and uniform processing environment.

Isolating the Material from Air

The tube, typically made of ceramic, quartz, or a metal alloy, can be sealed at both ends. This allows operators to pump out the ambient air to create a vacuum or, more commonly, to purge the chamber and fill it with a specific gas.

This capability is critical for preventing oxidation and other unwanted chemical reactions that would occur if materials were heated in the presence of oxygen. It enables processing with inert gases (like argon or nitrogen) or reactive gases depending on the desired outcome.

Achieving Uniform and Precise Heat

Heating elements surround the exterior of the tube, providing radiant heat. This configuration creates a zone of highly uniform temperature along the length of the tube, which is essential for ensuring that every part of the batch receives the exact same thermal treatment.

This precision is key to the repeatability required in both small-batch and large-scale industrial production.

Key Production Applications

While versatile, tubular furnaces excel in several specific, high-value production processes.

Material Property Modification (Heat Treatment)

Many industries rely on heat to alter the physical or chemical structure of a material.

Annealing is a process of heating and slow cooling used to soften metals, improve ductility, and relieve internal stresses. Hardening involves controlled heating and rapid cooling to increase a material's strength.

Sintering is a process used in ceramics and metallurgy to fuse powders into a solid, coherent mass by applying heat below the material's melting point. The controlled atmosphere prevents impurities and ensures proper bonding.

Advanced Material Deposition (CVD)

Chemical Vapor Deposition (CVD) is a cornerstone process in the semiconductor and nanotechnology industries. In CVD, precursor gases are introduced into the heated tube where they react and decompose.

The result is the deposition of a high-purity, high-performance thin film or coating onto a substrate. This is how many of the complex, layered materials in microchips and advanced optics are built.

Synthesis and Decomposition

Tubular furnaces are effectively small-scale chemical reactors. They are used for chemical synthesis, where heat drives a reaction to create new compounds.

They are also used for pyrolysis and thermal decomposition, processes that use heat in an oxygen-free environment to break down complex materials (like polymers) into simpler components without combustion.

Understanding the Trade-offs

The precision of a tubular furnace comes with important limitations that must be considered in a production context.

Limited Batch Size and Geometry

The tubular shape inherently restricts the size and shape of the components that can be processed. It is ideal for small parts, powders, wafers, or wires, but impractical for large or bulky items.

Lower Throughput

Compared to larger, open-air batch ovens, the process of loading, sealing, purging the atmosphere, heating, cooling, and unloading a tube furnace is often slower. This makes it less suitable for high-volume, low-margin manufacturing where speed is the primary driver.

Higher Relative Cost and Complexity

The systems required for vacuum pumping, gas mixing and delivery, and precise temperature control add significant cost and complexity compared to a simple heat-treating oven. This investment is only justified when atmospheric control is a non-negotiable requirement.

Making the Right Choice for Your Process

Deciding if a tubular furnace is appropriate depends entirely on whether your process requires the environmental control it provides.

- If your primary focus is modifying bulk properties like hardness or stress relief: A tubular furnace is essential only if the material cannot tolerate any surface oxidation or contamination from air.

- If your primary focus is creating advanced coatings or thin films: A specialized CVD tubular furnace is often the standard and necessary tool for the job.

- If your primary focus is synthesizing or analyzing sensitive chemical compounds: The sealed, controlled environment of a tube furnace is non-negotiable for achieving pure and predictable results.

Ultimately, selecting a tubular furnace is a decision to prioritize environmental control and process precision over raw throughput and volume.

Summary Table:

| Application | Key Benefit | Material Examples |

|---|---|---|

| Annealing | Relieves stress, improves ductility | Metals, alloys |

| Sintering | Fuses powders into solid mass | Ceramics, metal powders |

| CVD | Deposits high-purity thin films | Semiconductors, optics |

| Synthesis | Creates new compounds in controlled environment | Polymers, chemicals |

| Pyrolysis | Breaks down materials without combustion | Waste, biomass |

Ready to enhance your production with precise thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industrial settings. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental and production needs. Contact us today to discuss how our solutions can optimize your processes and deliver superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety