In the semiconductor industry, SC Type Silicon Carbide (SiC) heating elements are primarily used in high-temperature diffusion furnaces and other thermal processing steps. Their selection for this demanding role is driven by their high purity and exceptional thermal stability, which are critical for producing high-quality, defect-free semiconductor devices.

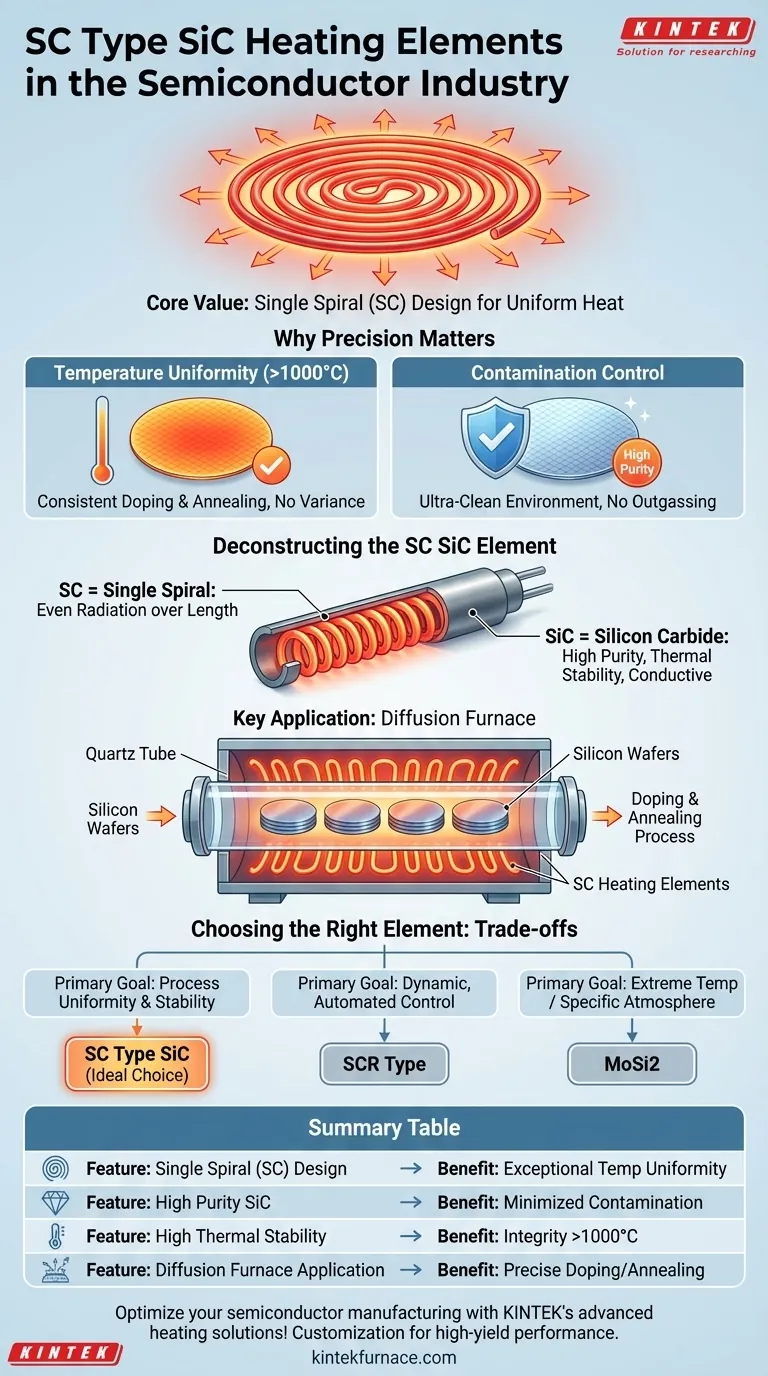

The core value of an SC Type SiC element in semiconductor manufacturing is not just its ability to reach high temperatures. It is the single spiral (SC) design that delivers exceptionally uniform heat, a non-negotiable requirement for processes where even minor temperature variations can compromise an entire batch of wafers.

The Role of Precision Heating in Semiconductor Manufacturing

The creation of integrated circuits is a process of immense precision. Thermal processing steps are foundational to this work, and the quality of the heating element directly impacts the final product yield and performance.

Why Temperature Uniformity is Paramount

Semiconductor processes like doping and annealing require wafers to be heated to precise temperatures, often exceeding 1000°C.

Even a small temperature variance across a single wafer—or between different wafers in a batch—can alter the intended electrical properties, leading to device failure. The goal is to create a perfectly stable and homogenous thermal environment.

The Contamination Challenge

Semiconductor fabrication occurs in an ultra-clean environment. Any impurities introduced during a heating cycle can become embedded in the silicon wafer, permanently damaging the microscopic circuits.

Heating elements must therefore be constructed from high-purity materials that do not outgas or shed particles at high temperatures.

Deconstructing the SC Type SiC Element

The designation "SC" and the material "SiC" both point to the specific characteristics that make these elements suitable for such a sensitive application.

"SC" Refers to the Single Spiral Design

The "SC" in the name stands for Single Spiral. This refers to the physical construction of the heating element, which is designed to radiate heat evenly over its entire length.

This design optimizes for spatial temperature uniformity, making it ideal for large furnaces where a consistent temperature must be maintained across a wide area. This ensures every wafer in a furnace tube experiences the same thermal profile.

The Material Advantage: High-Purity Silicon Carbide

Silicon carbide is a ceramic material with a unique combination of properties. It has high electrical resistance, allowing it to generate heat efficiently, but also good thermal conductivity, which helps distribute that heat smoothly.

Crucially, it possesses excellent thermal stability, meaning it resists degradation and maintains its structural integrity at the extreme temperatures required for semiconductor processing.

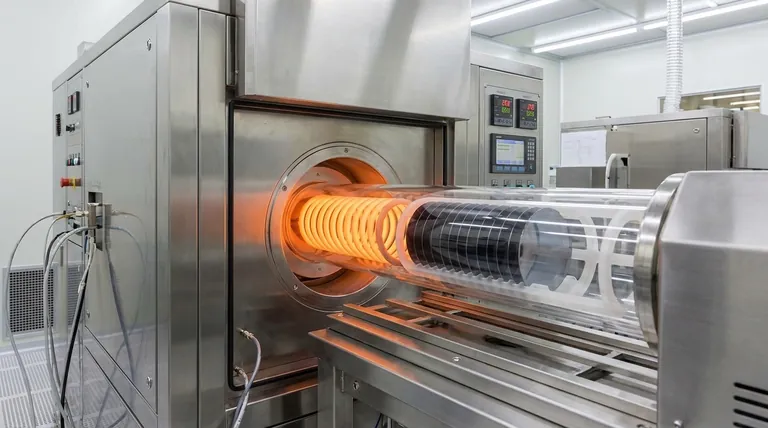

The Key Application: Diffusion Furnaces

In a diffusion furnace, a batch of silicon wafers is placed inside a quartz tube surrounded by heating elements. The SC Type's ability to provide uniform, stable, and clean heat is perfectly matched to this task.

This ensures that dopant gases are driven into the silicon wafers consistently, creating the precise transistor characteristics required for modern electronics.

Understanding the Trade-offs

While SC Type SiC elements are a workhorse for uniform heating, they exist within a broader ecosystem of industrial heating solutions. Understanding their position helps clarify their ideal use case.

Simplicity and Reliability

The SC Type element's strength is its robust and straightforward design, which provides reliable, uniform heat. It is a proven solution for applications where consistency is the primary goal.

Comparison with Other Element Types

Other elements, like the SCR Type, are designed for more sophisticated thermal management systems requiring rapid, automated temperature adjustments. These are often found in advanced electronics manufacturing where dynamic control is needed.

Similarly, Molybdenum Disilicide (MoSi2) elements are another common choice for high-temperature furnaces. The decision between SiC and MoSi2 often comes down to specific factors like maximum operating temperature, atmospheric compatibility, and cost.

Physical Limitations

As ceramic components, SiC heating elements are inherently brittle. Care must be taken during installation and maintenance to avoid mechanical shock, which can cause them to fracture.

How to Apply This to Your Process

Choosing the correct heating element requires aligning its core design benefits with the most critical requirements of your thermal process.

- If your primary focus is process uniformity and stability: The SC Type SiC element is an ideal choice due to its single spiral design, which is engineered to minimize temperature variance.

- If your primary focus is dynamic, automated temperature control: You may need to evaluate more advanced options like SCR Type elements, which are better suited for sophisticated thermal management.

- If your process involves specific chemical atmospheres or extreme temperatures: A detailed comparison against alternatives like MoSi2 is necessary to ensure material compatibility and longevity.

Ultimately, selecting the right heating technology hinges on a clear understanding of the unyielding demands of your specific manufacturing goal.

Summary Table:

| Feature | Benefit for Semiconductor Industry |

|---|---|

| Single Spiral (SC) Design | Provides exceptional temperature uniformity for consistent wafer processing |

| High Purity Silicon Carbide | Minimizes contamination in ultra-clean environments |

| High Thermal Stability | Maintains integrity at temperatures over 1000°C |

| Application in Diffusion Furnaces | Ensures precise doping and annealing of silicon wafers |

Optimize your semiconductor manufacturing with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing yield and performance. Contact us today to discuss how our SC Type SiC elements and other products can elevate your thermal processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is surface load and why is it important for heating elements? Optimize Lifespan and Safety

- What is the function of radiation shields in high-temperature viscosity measurement? Ensure 0.53% Precision Accuracy

- How does molybdenum disilicide behave at high temperatures? Unlock Superior Performance in Extreme Heat

- What are some common industrial applications of ceramic infrared heaters? Boost Efficiency in Drying, Thermoforming, and Food Processing

- What is the role of K-type thermocouples in monitoring photocatalytic reactions? Key to Precise Thermal Data

- How does staged combustion in double-P radiant tubes suppress NOx? Advanced Emission Control Solutions

- Why is high-purity graphite preferred for silicon melt stirrer blades? Ensure Purity in High-Temp Monitoring

- How does MoSi2 compare to molybdenum in high-temperature applications? Discover the Best Material for Extreme Heat