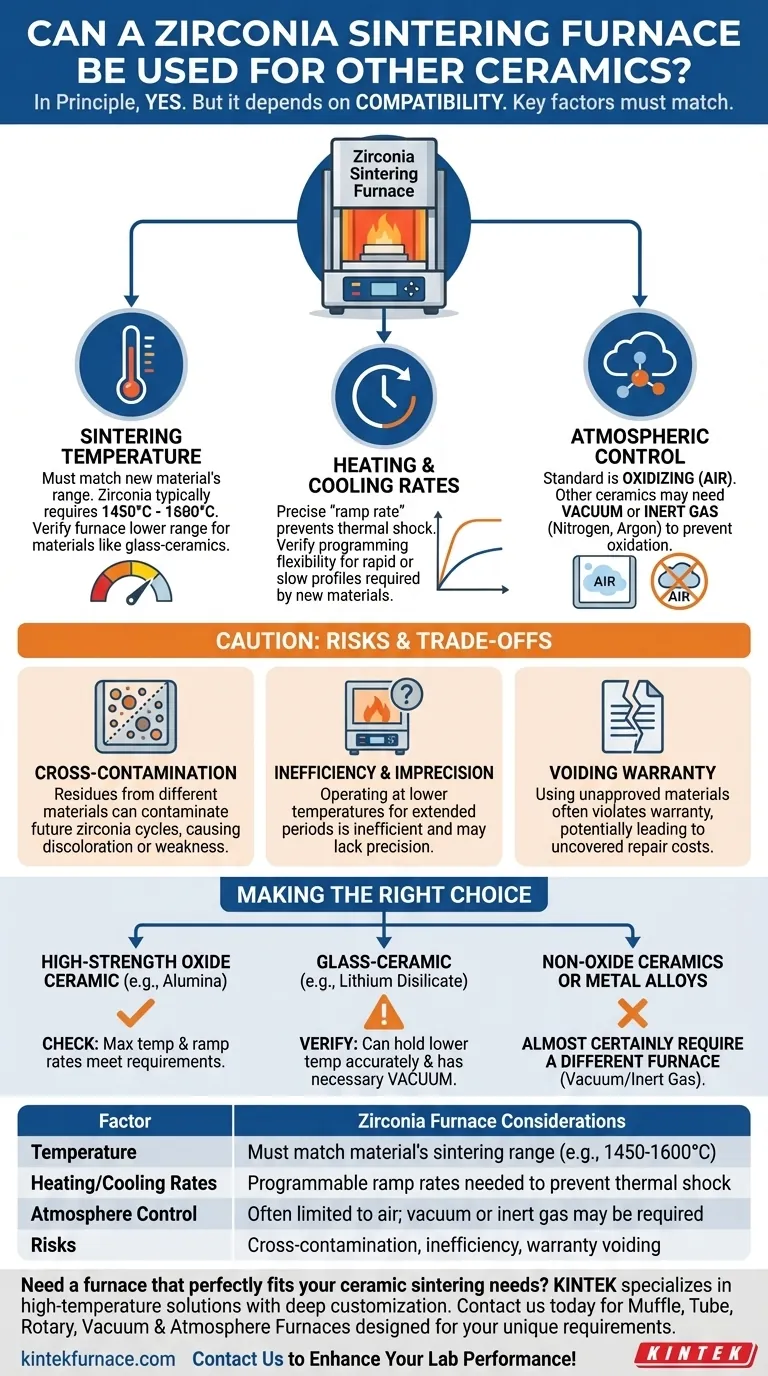

In principle, yes, a furnace designed for sintering zirconia can often be used for other ceramic materials. However, its suitability is not guaranteed and depends entirely on matching the furnace's specific capabilities with the unique processing requirements of the new material. The most critical factors to verify are the maximum temperature, the programmability of heating and cooling rates, and the furnace's atmospheric control.

While a zirconia furnace is a powerful high-temperature tool, its utility for other materials is a matter of precise compatibility. The decisive factor is whether the furnace's technical specifications can perfectly replicate the new material's required sintering profile; any mismatch risks material failure, or even damage to the equipment itself.

The Core Requirements of Ceramic Sintering

Sintering is a precise thermal process that transforms a porous ceramic powder into a dense, solid object. Success hinges on controlling three key variables, which differ significantly between materials.

Sintering Temperature

Different ceramics require vastly different temperatures to achieve proper densification. Zirconia, for example, typically sinters at very high temperatures, often between 1450°C and 1600°C.

While a high-temperature zirconia furnace can technically achieve lower temperatures, you must verify that the target temperature for the new material falls within its operational range. Many glass-ceramics, for instance, sinter at much lower temperatures and may require a different type of furnace for optimal precision.

Heating and Cooling Rates

The speed at which a material is heated and cooled (its thermal "ramp rate") is just as critical as the peak temperature. This rate is carefully engineered to prevent thermal shock, which can cause cracks and internal stresses.

Zirconia often involves long, slow cycles. If you intend to sinter a material that requires a very rapid heating phase or an extremely controlled, slow cool-down, you must confirm that your furnace’s programming is flexible enough to accommodate that specific profile.

Atmospheric Control

This is often the most significant limiting factor. Standard dental zirconia is sintered in an oxidizing atmosphere (i.e., ambient air). The furnace simply heats the air inside the chamber.

Many other advanced ceramics, hard alloys, or cermets require sintering in a vacuum or an inert gas atmosphere (like nitrogen or argon). This is done to prevent oxidation, which would ruin the material's properties. Most zirconia furnaces are muffle furnaces not equipped for vacuum or gas-purging, making them fundamentally incompatible with these materials.

Understanding the Trade-offs and Risks

Using a zirconia furnace for an uncertified material is not a straightforward decision. You must weigh the potential benefits against significant risks.

The Risk of Cross-Contamination

Firing different materials in the same chamber can leave microscopic residues on the furnace walls, insulation, and heating elements.

These contaminants can become airborne in subsequent firing cycles and embed themselves in your zirconia restorations, potentially causing discoloration, reduced translucency, or compromised structural integrity.

Inefficiency and Imprecision

High-temperature furnaces are engineered for performance near their peak temperature. Operating them for extended periods at much lower temperatures can be inefficient and may lead to less accurate temperature control.

It's analogous to using a blast furnace to bake a cake; while technically possible, it lacks the precision needed for a perfect result.

Voiding Your Warranty

Virtually all furnace manufacturers specify which materials their equipment is designed and warrantied for. Using your furnace to fire unapproved materials is often a direct violation of the warranty terms.

If the furnace fails—even for a reason that seems unrelated—the manufacturer may refuse to cover the repair, leading to significant unexpected costs.

Making the Right Choice for Your Material

To determine if your furnace is suitable, you must perform a direct comparison of its specifications against the new material's official processing instructions.

- If your primary focus is sintering another high-strength oxide ceramic (like alumina): Check that your furnace's maximum temperature and programmable ramp rates meet or exceed the requirements for that specific material.

- If your primary focus is sintering a glass-ceramic (like lithium disilicate): You must verify the furnace can accurately hold the much lower required temperatures and, critically, perform any vacuum steps mandated by the material manufacturer.

- If your primary focus is sintering non-oxide ceramics or metal alloys: You will almost certainly need a different type of furnace that provides a controlled vacuum or inert gas atmosphere.

Ultimately, a thorough understanding of both your equipment's capabilities and your material's needs is the only path to guaranteeing successful and repeatable results.

Summary Table:

| Factor | Zirconia Furnace Considerations |

|---|---|

| Temperature | Must match material's sintering range (e.g., 1450-1600°C for zirconia) |

| Heating/Cooling Rates | Programmable ramp rates needed to prevent thermal shock |

| Atmosphere Control | Often limited to air; vacuum or inert gas may be required for other materials |

| Risks | Cross-contamination, inefficiency, warranty voiding |

Need a furnace that perfectly fits your ceramic sintering needs? KINTEK specializes in high-temperature solutions with deep customization. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems are designed to meet unique experimental requirements, ensuring precise temperature control, atmospheric management, and efficiency. Contact us today to discuss how we can enhance your lab's performance and deliver reliable results tailored to your materials!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency