Yes, a muffle furnace is a standard and effective tool for many common metal heat treatments. It is widely used for processes like annealing, tempering, and hardening because it can achieve the necessary high temperatures with precise control. However, its suitability depends entirely on the specific metal and the required quality of the final surface finish.

The core takeaway is that while a muffle furnace provides the necessary heat for treatment, it does not control the atmosphere inside the chamber. This exposure to air will cause surface oxidation on most steels, a critical factor you must plan for.

How a Muffle Furnace Functions for Heat Treatment

A muffle furnace's design is what makes it suitable for heating materials cleanly and uniformly. Understanding its basic principle clarifies its capabilities.

The Principle of Indirect Heating

The name "muffle furnace" comes from the muffle, which is a separate inner chamber that contains the workpiece. Heating elements, typically made of high-resistance wire, heat the outside of this chamber.

This design provides indirect heat, isolating your metal parts from the direct radiation of the heating elements. This ensures a more uniform temperature and prevents contamination from the byproducts of combustion that occur in a fuel-fired furnace.

Achieving and Holding Precise Temperatures

Successful heat treatment relies on hitting specific temperatures for a set duration. Muffle furnaces excel at this.

They are designed with effective insulation and digital control systems that allow you to set and maintain a target temperature with high accuracy. This precision is essential for processes like tempering, where a difference of even a few degrees can significantly alter the metal's final hardness and toughness.

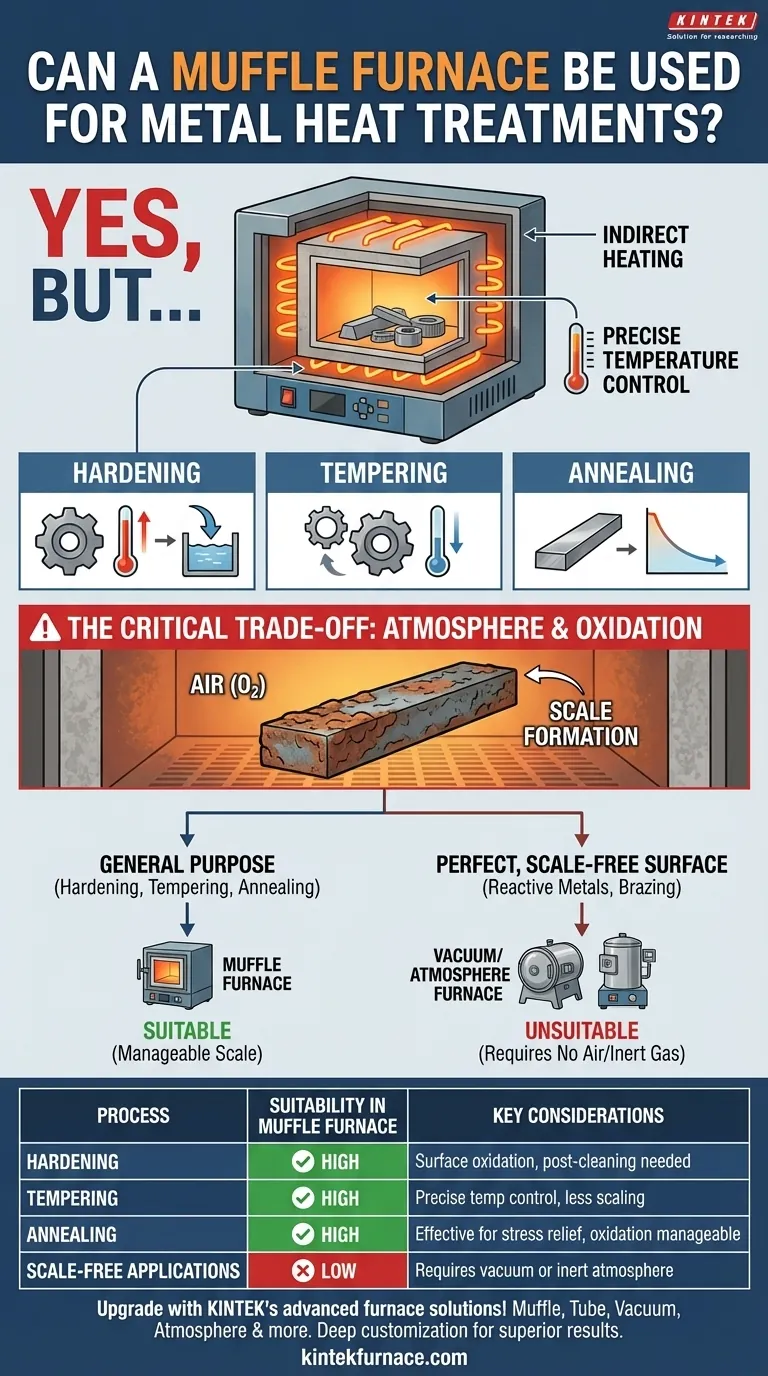

Common Metal Heat Treatments

Muffle furnaces are regularly used in both industrial and laboratory settings for several key processes:

- Hardening: Heating steel above its critical temperature and then quenching it to create a hard, brittle structure.

- Tempering: Reheating a hardened part to a lower temperature to reduce brittleness and increase toughness.

- Annealing: Heating and slowly cooling metal to soften it, relieve internal stresses, and improve its machinability.

Understanding the Critical Trade-offs

The primary limitation of a standard muffle furnace is its lack of atmospheric control. This is a non-negotiable factor that dictates its proper use.

The Inevitable Problem of Oxidation

A muffle furnace operates with normal air inside the chamber. When you heat steel in the presence of oxygen, its surface will react and form an oxide layer, commonly known as scale.

This scale can be problematic, as it can affect final dimensions and surface finish. For many applications, this scale must be removed after treatment through grinding, sandblasting, or pickling.

When Is a Muffle Furnace the Right Choice?

A muffle furnace is perfectly adequate when minor surface oxidation is acceptable or easily managed.

This includes general-purpose hardening of tool steels where the part will be finished or ground after treatment, or tempering processes where the lower temperatures produce less aggressive scaling. It's also suitable for many non-ferrous metals where oxidation is less of a concern or is easily cleaned.

The Limitation: No Vacuum or Inert Gas

For materials highly sensitive to oxygen or for processes like brazing where surfaces must remain perfectly clean, a muffle furnace is unsuitable.

These applications demand a vacuum furnace, which removes all air to prevent any chemical reactions on the metal's surface. Alternatively, an atmosphere furnace can be used, which replaces the air with an inert gas like argon to protect the workpiece.

Making the Right Choice for Your Goal

Selecting the correct furnace is about matching the equipment's capabilities to the metallurgical requirements of your project.

- If your primary focus is general-purpose hardening or tempering: A muffle furnace is an excellent, cost-effective choice, but you must be prepared to manage surface scale after treatment.

- If your primary focus is annealing or stress-relieving common steels and alloys: A muffle furnace is a reliable tool, especially if the final part will be machined or cleaned.

- If your primary focus is processing reactive metals or achieving a perfectly clean, scale-free surface: You must use a vacuum or controlled-atmosphere furnace to prevent oxidation and ensure material integrity.

Ultimately, choosing the right furnace requires understanding that the heat is only one part of the equation; the atmosphere it creates is just as important.

Summary Table:

| Process | Suitability in Muffle Furnace | Key Considerations |

|---|---|---|

| Hardening | High | Surface oxidation occurs; post-treatment cleaning needed |

| Tempering | High | Precise temperature control; less scaling at lower temps |

| Annealing | High | Effective for stress relief; oxidation manageable |

| Scale-free Applications | Low | Requires vacuum or inert atmosphere for protection |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior metal heat treatments. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production