At its core, vacuum annealing is an indispensable process for high-performance rare metals like titanium and zirconium because it protects them from atmospheric contamination at high temperatures. By removing oxygen and other reactive gases, the vacuum environment prevents the formation of brittle surface layers, relieves internal stresses, and refines the material's internal structure. This ensures the metals achieve the exceptional strength, toughness, and reliability demanded by critical industries like aerospace, nuclear power, and defense.

For highly reactive metals used in mission-critical applications, the vacuum is not merely a process enhancement—it is a fundamental requirement. It creates the chemically pure environment necessary to unlock the material's intended mechanical properties without compromising its integrity.

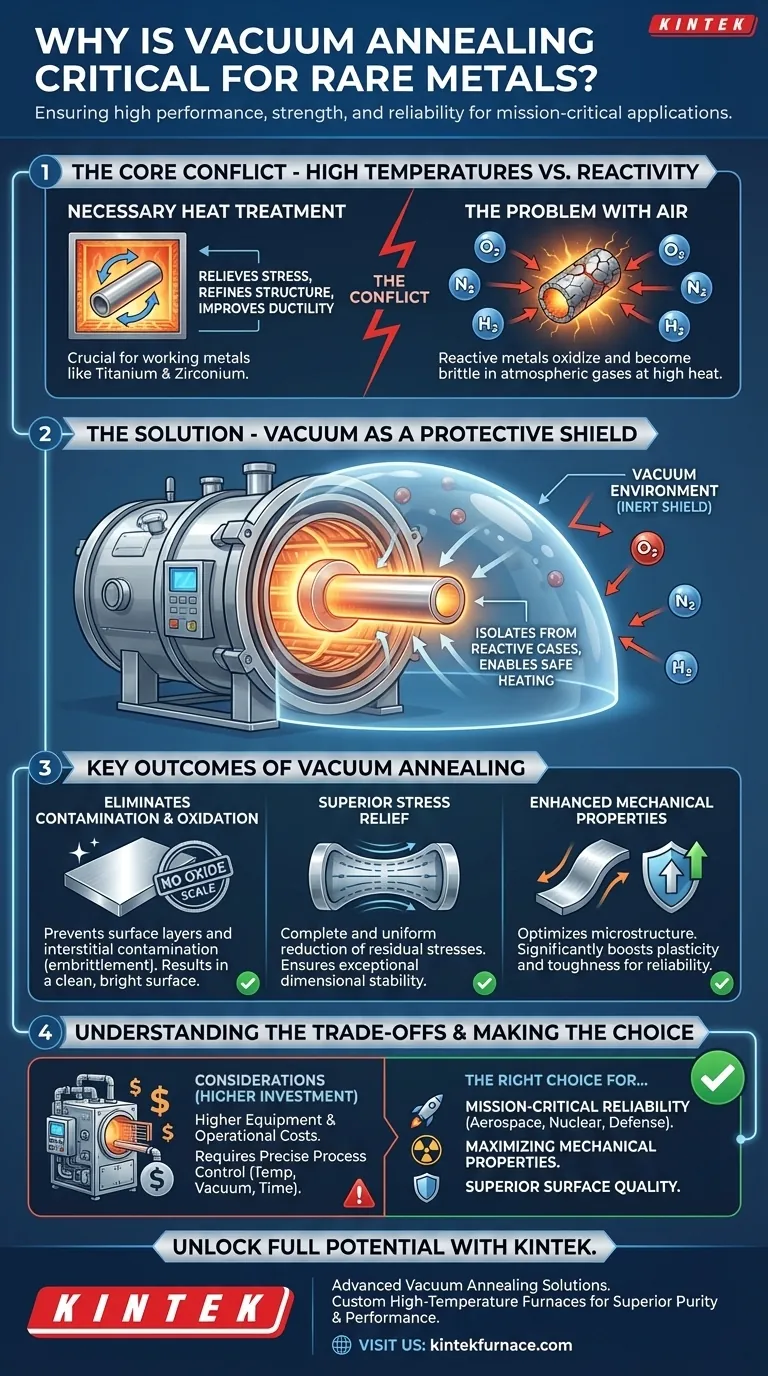

The Core Challenge: Reactivity at High Temperatures

To understand the importance of vacuum annealing, we must first understand the fundamental conflict between the need for heat treatment and the inherent nature of rare metals.

Why Heat Treatment is Necessary

Metals that have been worked—through processes like forging, rolling, or machining—accumulate significant internal stress. This residual stress can make the material unstable and prone to cracking or warping over time.

Annealing is a heat treatment process that allows the metal's crystalline structure to relax and reform, effectively "resetting" it to a more stable, lower-energy state. This process is crucial for improving ductility (flexibility) and toughness.

The Problem with Air

The challenge is that many rare metals, especially titanium and zirconium, are extremely reactive at the high temperatures required for annealing.

When heated in the presence of air, these metals will readily react with oxygen, nitrogen, and even hydrogen. This reaction forms a hard, brittle surface layer (like an oxide scale) that severely degrades the material's mechanical properties and fatigue life.

The Vacuum as a Protective Shield

Vacuum annealing solves this problem by removing the reactive elements from the equation. By performing the heat treatment inside a vacuum furnace, the material is isolated from atmospheric gases.

This inert environment allows the metal to be heated to the necessary temperature to relieve stress and refine its grain structure without the risk of damaging chemical reactions.

Key Outcomes of Vacuum Annealing

Performing this process in a vacuum yields several critical benefits that are simply not achievable with conventional heat treatment methods.

1. Eliminating Contamination and Oxidation

The most immediate benefit is a clean, bright surface free of the oxide layers that form in an oxygen-rich environment.

More importantly, this prevents interstitial contamination, where elements like oxygen and nitrogen diffuse into the metal's atomic lattice, causing embrittlement and compromising the entire component.

2. Superior Stress Relief

By allowing the material to reach its annealing temperature in a pure environment, the process enables a more complete and uniform reduction of residual stresses.

This results in exceptional dimensional stability, which is vital for complex components that must maintain precise tolerances during assembly and operation.

3. Enhanced Mechanical Properties

The ultimate goal of annealing is to improve the material's performance. Vacuum annealing is uniquely effective at this for rare metals.

By preventing contamination and enabling full stress relief, the process optimizes the material's microstructure. This directly enhances plasticity (the ability to deform without fracturing) and toughness (the ability to absorb energy before fracturing), making the final part far more reliable under demanding conditions.

Understanding the Trade-offs

While vacuum annealing is superior, it's important to recognize the associated considerations. It is a deliberate engineering choice driven by necessity.

Higher Equipment and Operational Costs

Vacuum furnaces are inherently more complex and expensive than standard atmospheric furnaces. They require sophisticated pumping systems, seals, and controls, leading to higher capital investment and operational costs.

Precise Process Control is Non-Negotiable

The effectiveness of the process depends on rigorous control over temperature, time-at-temperature, cooling rates, and the level of vacuum achieved. Any deviation from the specified parameters can result in incomplete annealing or failure to achieve the desired material properties.

It Is Not a Universal Requirement

For less reactive metals or applications where the ultimate material performance is not a life-or-death requirement, simpler and less expensive methods like annealing in an inert gas (e.g., argon) atmosphere may be sufficient.

Making the Right Choice for Your Goal

Selecting the right heat treatment is about matching the process to the performance requirements of the final component.

- If your primary focus is mission-critical reliability (aerospace, defense, nuclear): Vacuum annealing is non-negotiable to guarantee the material integrity and predictable performance required to prevent catastrophic failure.

- If your primary focus is maximizing mechanical properties: Vacuum annealing provides the purest environment to achieve the highest possible ductility, toughness, and fatigue life from a given rare metal alloy.

- If your primary focus is surface quality and brightness: The vacuum process inherently prevents oxidation, delivering a clean component that may not require subsequent surface treatments like acid pickling.

Ultimately, choosing vacuum annealing is a decision to prioritize the absolute integrity of the material over all other considerations.

Summary Table:

| Aspect | Key Details |

|---|---|

| Purpose | Protects rare metals from atmospheric contamination during high-temperature heat treatment to ensure material integrity. |

| Key Benefits | Eliminates oxidation and contamination, relieves internal stresses, refines microstructure, and improves mechanical properties like ductility and toughness. |

| Industries Served | Aerospace, nuclear power, defense, and other mission-critical applications requiring high reliability. |

| Process Considerations | Requires precise control of temperature, time, cooling rates, and vacuum levels; higher costs compared to standard methods. |

Unlock the Full Potential of Your Rare Metals with KINTEK's Advanced Vacuum Annealing Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements for vacuum annealing. Whether you're in aerospace, nuclear, or defense, our expertise ensures your rare metals achieve superior purity, stress relief, and mechanical performance. Don't compromise on quality—contact us today to discuss how we can tailor a solution for your critical applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment