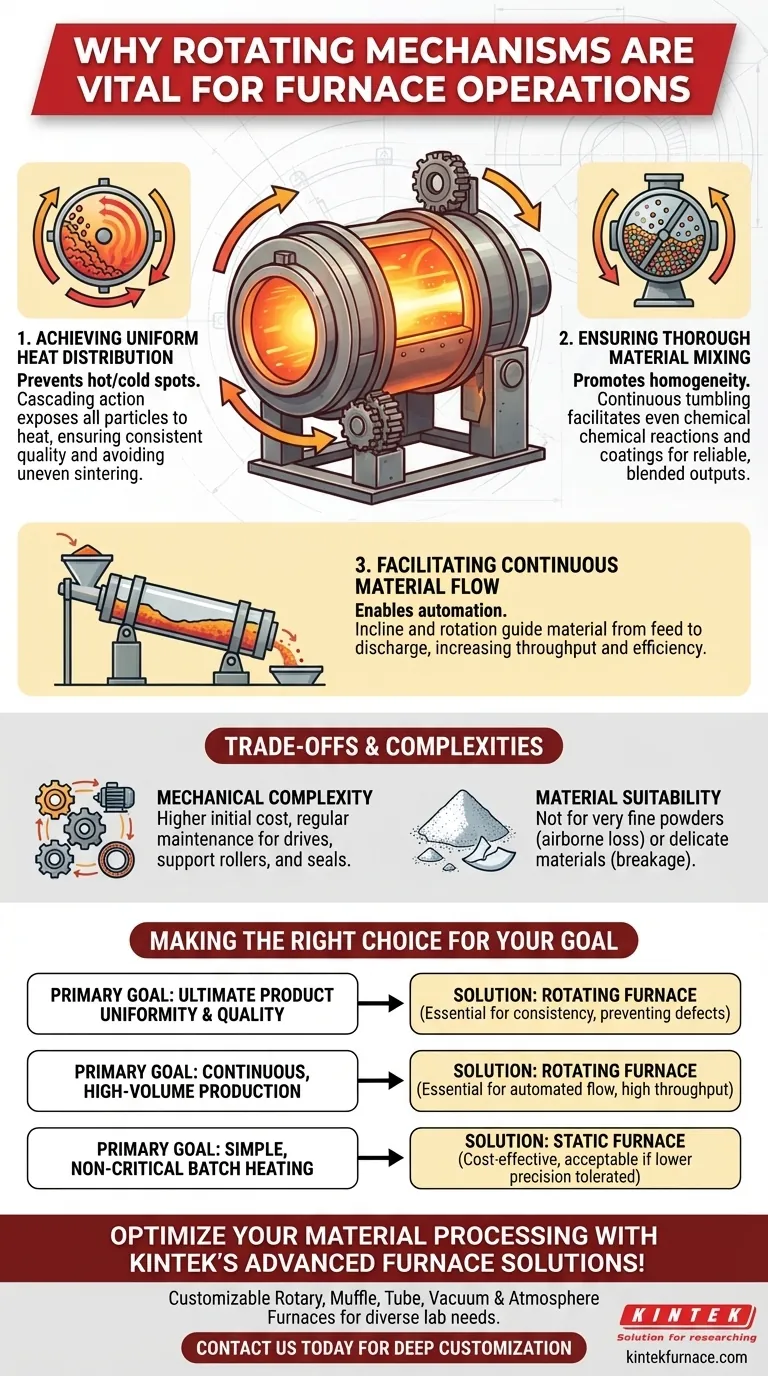

In furnace operations, the rotating mechanism is fundamental for achieving consistent, high-quality material processing. The rotation serves three critical and interconnected functions: it ensures uniform heat distribution, promotes thorough material mixing, and facilitates the continuous movement of materials through the furnace chamber.

A rotating furnace moves beyond simple heating. It becomes a dynamic processing environment where rotation is the primary tool for controlling heat transfer and material consistency, directly determining the final product's quality and process efficiency.

The Core Functions of Rotation

The importance of the rotating mechanism is best understood by breaking down its three primary effects on the material being processed. Each function addresses a potential point of failure in a static (non-rotating) heating environment.

Achieving Uniform Heat Distribution

In a static furnace, material at the bottom and center of a pile heats much slower than material on the surface. This temperature difference leads to inconsistent results.

Rotation solves this by constantly tumbling the material. This action, known as cascading, continuously exposes all particles to the heat source and the hot furnace walls, preventing any single area from becoming a hot or cold spot.

This prevents common defects like local overheating or uneven sintering, which are critical for producing a uniform, high-quality final product.

Ensuring Thorough Material Mixing

For processes that involve chemical reactions, coatings, or creating homogenous blends, simple heating is not enough. The materials must be thoroughly mixed.

The rotating action forces the particles to tumble over one another, creating a highly effective and continuous mixing effect. This ensures reactants are evenly distributed and that every particle is processed to the same degree.

Think of it like a large-scale cement mixer or rock tumbler; the goal is to create a perfectly homogenous output from a potentially varied input.

Facilitating Continuous Material Flow

For industrial-scale production, efficiency is key. A rotating furnace, often called a rotary kiln, is designed for a continuous, automated workflow.

The furnace is typically set at a slight angle. The combination of this incline and the constant rotation gently guides the material from the feed end to the discharge end.

This design transforms the furnace from a single-batch unit into a continuous processing line, significantly increasing throughput and reducing manual labor.

Understanding the Trade-offs and Complexities

While essential for many applications, a rotating mechanism introduces complexities that are not present in simpler, static furnaces.

Mechanical Complexity and Maintenance

A rotating system includes motors, drive gears, support rollers, and, critically, rotating seals. These components add to the initial cost and require a regular maintenance schedule to ensure reliability.

Failure of any part of the drive or support system can lead to costly downtime. The seals, in particular, are wear items that must be monitored and replaced to maintain atmosphere control.

Material Suitability

The tumbling action of a rotary furnace is not suitable for all materials. Extremely fine powders can become airborne and lost, while fragile or delicate materials may break apart or be damaged by the cascading motion.

For these materials, a static or belt furnace might be a more appropriate choice, even if it means sacrificing some degree of thermal uniformity.

Making the Right Choice for Your Goal

The decision to use a rotating furnace depends entirely on your processing objectives.

- If your primary focus is ultimate product uniformity and quality: The rotation is non-negotiable, as it is the most effective way to prevent defects caused by uneven heating and mixing.

- If your primary focus is continuous, high-volume production: The rotating mechanism is essential for creating an efficient, automated material flow from input to output.

- If your primary focus is simple heating of non-critical batches: A less complex and more cost-effective static furnace may be the better solution, provided your process can tolerate less temperature precision.

Ultimately, understanding the function of rotation empowers you to match the furnace technology directly to your material processing goals.

Summary Table:

| Function | Benefit | Impact on Process |

|---|---|---|

| Uniform Heat Distribution | Prevents hot/cold spots | Ensures consistent product quality and avoids defects like uneven sintering |

| Thorough Material Mixing | Promotes homogeneity | Facilitates even chemical reactions and coatings for reliable outputs |

| Continuous Material Flow | Enables automation | Increases throughput and reduces manual labor in industrial settings |

Optimize your material processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our rotating furnace technology can enhance your efficiency and product quality!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing