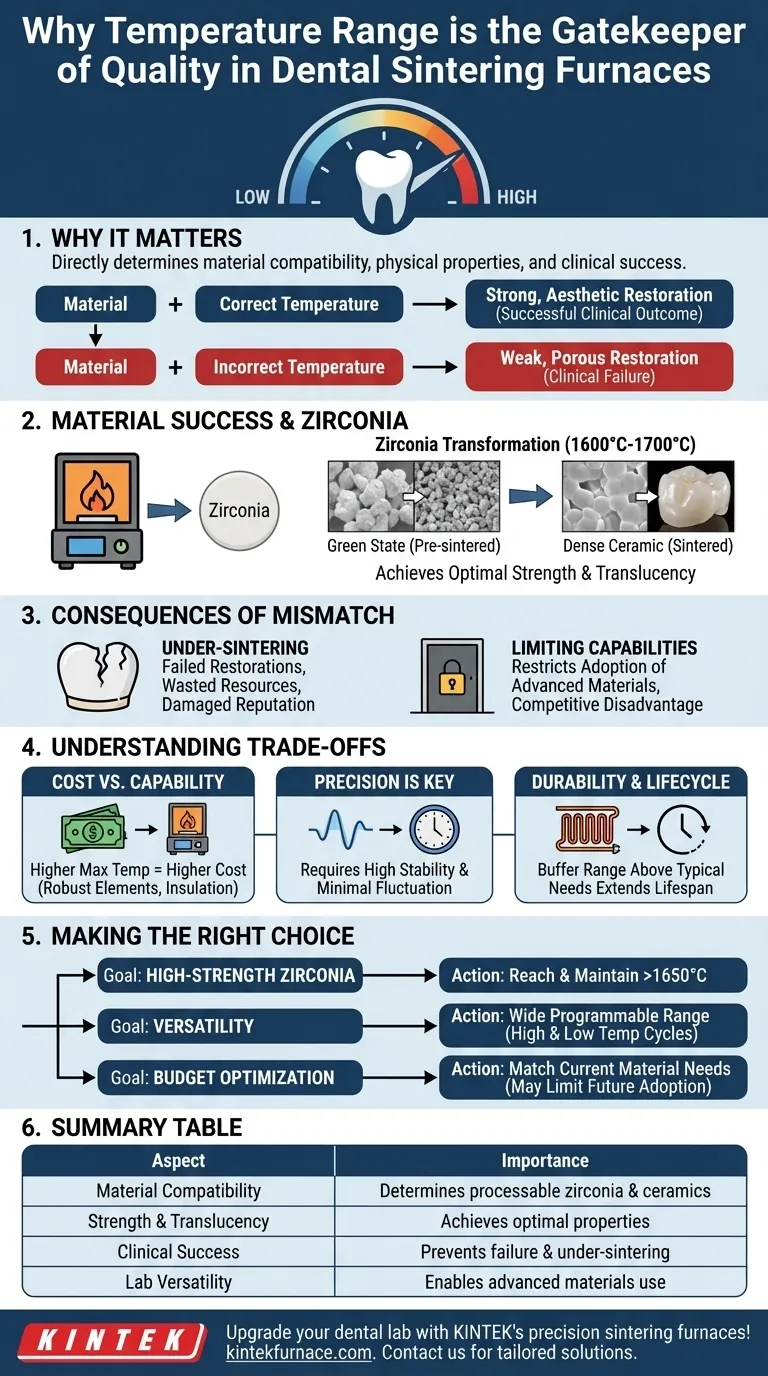

In short, a dental sintering furnace's temperature range is its most critical specification because it directly determines which materials you can process and the final clinical success of the restoration. Different materials, especially advanced zirconia, require extremely specific and high temperatures to transform from a weak, chalky state into a durable and aesthetic final product. If the furnace cannot reach and hold the required temperature, the restoration will fail.

A furnace's temperature range is not just a technical detail; it is the fundamental gatekeeper of quality. It dictates material compatibility, defines the physical properties of the final restoration, and ultimately impacts both the profitability of the lab and the long-term satisfaction of the patient.

Why Temperature Dictates Material Success

The entire purpose of sintering is to heat a porous material below its melting point until its particles bond together, dramatically increasing its density and strength. The temperature at which this happens is unique to each material.

Sintering Zirconia: The High-Heat Requirement

Zirconia is the primary reason high-temperature capabilities are essential. Most zirconia materials used for crowns and bridges require a peak sintering temperature between 1600°C and 1700°C.

Reaching this specific temperature is non-negotiable. It is the catalyst that transforms the pre-sintered, "green state" zirconia into a dense, biocompatible ceramic with the strength needed to withstand oral forces.

Achieving Optimal Strength and Translucency

The final temperature directly impacts the physical and aesthetic properties of the restoration. Proper sintering ensures the material reaches its target flexural strength and fracture toughness.

Furthermore, for modern, highly aesthetic zirconia, the sintering cycle—including the peak temperature—is precisely calibrated to achieve the desired level of translucency, allowing the final crown to mimic a natural tooth.

The Consequences of a Temperature Mismatch

Choosing a furnace with an inadequate temperature range is not a minor inconvenience; it is a direct cause of failed restorations and wasted resources.

Under-Sintering: A Recipe for Clinical Failure

If a furnace cannot reach the material manufacturer's prescribed temperature, the zirconia will be under-sintered. This results in a porous, weak restoration that is highly susceptible to fracture once placed in the patient's mouth.

This represents a complete loss of time and material for the lab and can damage your professional reputation.

Limiting Your Lab’s Capabilities

The dental materials market is constantly evolving. Newer zirconia formulations may offer better aesthetics or strength but could require different or higher sintering temperatures.

A furnace with a limited temperature range restricts your ability to adopt these advanced materials, placing your lab at a competitive disadvantage.

Understanding the Trade-offs

Selecting a furnace involves balancing capability with practical and economic realities. The maximum temperature is a key factor in this decision.

Cost vs. Capability

As a general rule, furnaces with higher maximum temperatures are more expensive. This is due to the need for more robust and durable heating elements (e.g., Molybdenum Disilicide - MoSi2) and superior insulation to safely contain the extreme heat.

It is crucial to assess the actual working temperatures of the materials you use most often.

Precision Is as Important as Power

Simply reaching a high temperature is not enough. The furnace must offer high precision and stability, holding the target temperature with minimal fluctuation.

Temperature instability during the critical sintering phase can introduce internal stresses and ruin an entire batch of restorations, regardless of whether the peak temperature was technically reached.

Durability and Lifecycle

Consistently operating a furnace at its absolute maximum stated temperature can shorten the lifespan of its heating elements. A furnace with a maximum range slightly above your typical sintering needs provides a buffer that can lead to greater long-term reliability.

Making the Right Choice for Your Goal

Your decision should be guided by a clear understanding of your lab's current needs and future ambitions.

- If your primary focus is high-strength zirconia: Ensure the furnace can comfortably reach and maintain at least 1650°C to accommodate the vast majority of zirconia discs on the market.

- If your primary focus is versatility: Seek a furnace with a wide programmable range that can handle high-temperature sintering for zirconia as well as lower-temperature cycles for other ceramics, stains, and glazes.

- If your primary focus is budget optimization: Match the furnace's capabilities directly to the materials you use now, but acknowledge this may limit your ability to adopt new, higher-temperature materials in the future.

Choosing the right furnace is a critical investment in the quality and consistency of your work.

Summary Table:

| Aspect | Importance |

|---|---|

| Material Compatibility | Determines which zirconia and ceramics can be processed |

| Strength & Translucency | Achieves optimal flexural strength and aesthetic properties |

| Clinical Success | Prevents under-sintering and restoration failure |

| Lab Versatility | Enables use of advanced materials and competitive edge |

Upgrade your dental lab with KINTEK's precision sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your furnace meets unique experimental needs, enhancing material processing and clinical outcomes. Contact us today to discuss how our tailored solutions can boost your lab's efficiency and success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations