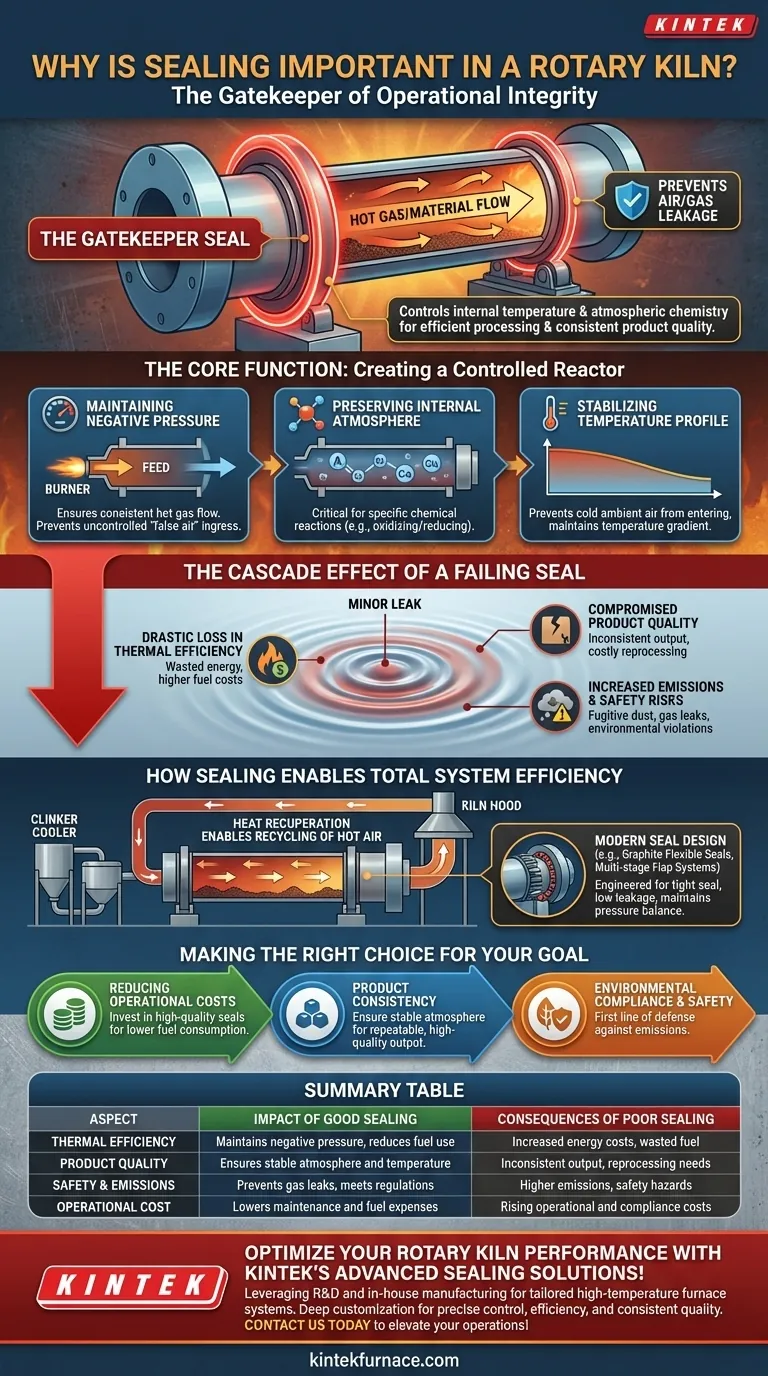

In a rotary kiln, proper sealing is the gatekeeper of operational integrity. It is a system designed to prevent air from leaking into the kiln and hot gases or material from leaking out. This control is absolutely critical for maintaining the stable internal temperature and specific atmospheric chemistry required for efficient processing and consistent product quality.

A rotary kiln seal is not merely a physical barrier. It is a critical control mechanism that directly governs thermal efficiency, product quality, and operational cost. Treating a failing seal as a simple leak misses its profound, systemic impact on the entire process.

The Core Function: Creating a Controlled Reactor

A rotary kiln is not just a heated, rotating tube; it is a highly controlled chemical reactor. Effective sealing is what makes this control possible.

Maintaining Negative Pressure

Most rotary kilns operate under a slight negative pressure to ensure a consistent flow of hot gas from the burner towards the material feed end.

A poor seal breaks this pressure differential. It allows uncontrolled "false air" from the outside to be sucked into the kiln, disrupting the carefully managed process flow.

Preserving the Internal Atmosphere

Many processes require a specific chemical atmosphere, such as an oxidizing or reducing environment, to achieve the desired reactions.

Uncontrolled air ingress from a failing seal completely compromises this atmospheric chemistry. This can lead to incomplete reactions, unwanted byproducts, and a final product that fails to meet specifications.

Stabilizing the Temperature Profile

A kiln is designed with a specific temperature gradient along its length. A failing seal allows cold ambient air to enter the system.

This incoming cold air must be heated to the process temperature, which consumes a massive amount of extra fuel. It also creates cold spots that disrupt the temperature profile, harming the efficiency of the heat transfer to the material.

The Cascade Effect of a Failing Seal

A minor leak is rarely a minor problem. Its consequences ripple through the entire operation, creating significant financial and operational burdens.

Drastic Loss in Thermal Efficiency

The single biggest impact of a poor seal is a sharp decline in thermal efficiency. Every cubic meter of false air that enters the kiln is wasted energy, driving up fuel consumption and operational costs.

As noted in lime kiln operations, persistent air leakage directly leads to higher energy bills and forces expensive equipment upgrades just to maintain baseline performance.

Compromised Product Quality

When the internal atmosphere and temperature are unstable, the final product becomes inconsistent. This results in wasted material, costly reprocessing, and an inability to guarantee product homogeneity.

The kiln's primary advantage of producing a uniform product is entirely dependent on the stability that good sealing provides.

Increased Emissions and Safety Risks

A failing seal works both ways. It not only lets cold air in but also allows hot, dust-laden process gas to escape into the plant.

This creates a significant safety hazard for personnel and can lead to violations of environmental emissions regulations. Effective sealing is a prerequisite for any modern emission control system to function properly.

How Sealing Enables Total System Efficiency

Modern kilns are designed as integrated systems where every component contributes to efficiency. The seal is a linchpin that enables other components to function.

Enabling Heat Recuperation

High-efficiency systems often use a kiln hood to capture extremely hot air from the clinker cooler and recycle it back into the kiln as combustion air.

This process of heat recuperation can only work in a well-sealed system. If the kiln has significant leaks, the pressure balance is thrown off, and the ability to efficiently recycle this valuable heat is lost, wasting fuel.

The Role of Modern Seal Design

To combat these issues, modern kilns employ advanced designs like graphite flexible seals or multi-stage flap systems.

These technologies are specifically engineered to maintain a tight seal despite the thermal expansion and rotation of the kiln shell, ensuring a low air leakage rate and maximizing the benefits of a controlled environment.

Making the Right Choice for Your Goal

Evaluating your kiln's sealing should be a top priority. Your specific goal will determine your focus.

- If your primary focus is reducing operational costs: Investing in high-quality, low-leakage seals provides a direct and measurable return through lower fuel consumption.

- If your primary focus is product consistency: Recognize that a stable internal atmosphere, guaranteed only by effective seals, is non-negotiable for repeatable, high-quality output.

- If your primary focus is environmental compliance and safety: View the kiln seal as your first and most important line of defense against fugitive dust and gas emissions.

Ultimately, mastering the seal is mastering the efficiency, reliability, and profitability of your entire rotary kiln operation.

Summary Table:

| Aspect | Impact of Good Sealing | Consequences of Poor Sealing |

|---|---|---|

| Thermal Efficiency | Maintains negative pressure, reduces fuel use | Increased energy costs, wasted fuel |

| Product Quality | Ensures stable atmosphere and temperature | Inconsistent output, reprocessing needs |

| Safety & Emissions | Prevents gas leaks, meets regulations | Higher emissions, safety hazards |

| Operational Cost | Lowers maintenance and fuel expenses | Rising operational and compliance costs |

Optimize your rotary kiln performance with KINTEK's advanced sealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Rotary Furnaces, to ensure precise control, enhanced efficiency, and consistent product quality. Our deep customization capabilities address your unique process requirements, reducing costs and boosting reliability. Contact us today to discuss how we can elevate your operations!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results