In short, regular maintenance is essential for a dental sintering furnace to ensure the consistent quality of dental restorations, maximize the lifespan of your investment, and guarantee operational reliability. Because these furnaces are precision instruments central to a lab's output, their upkeep directly impacts clinical outcomes, financial stability, and overall efficiency.

A sintering furnace is not just another piece of lab equipment; it is the final gatekeeper of quality for your most advanced restorations. Viewing maintenance as an operational cost is a mistake—it is a direct investment in product consistency, risk mitigation, and the long-term profitability of your lab.

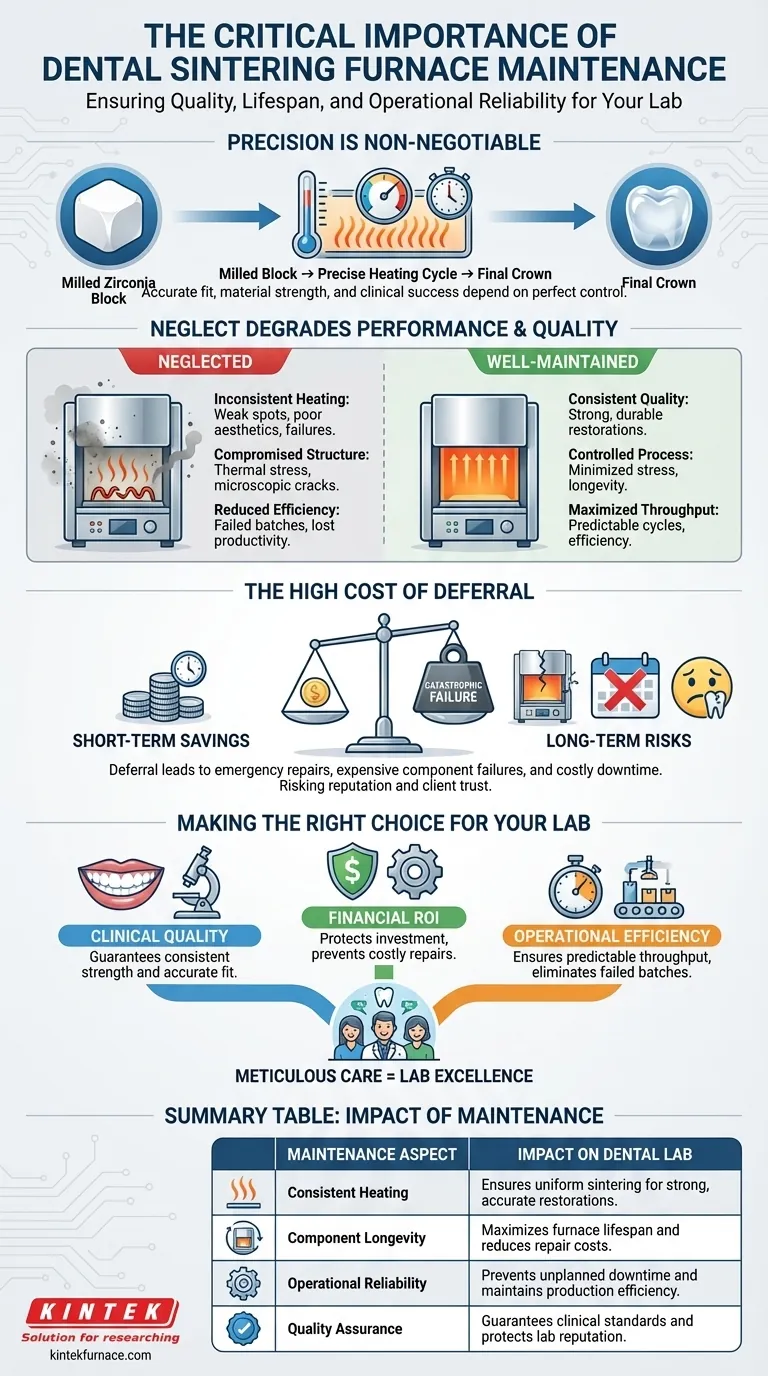

The Role of Precision in Sintering

A sintering furnace's job is to transform a chalky, milled zirconia framework into a dense, biocompatible, and durable final restoration. This transformation relies on absolute precision.

From Milled Block to Final Crown

The sintering process fires the restoration at exact temperatures for specific durations. This carefully controlled heat cycle is what gives the final product its required strength, translucency, and structural integrity.

Why Perfect Control is Non-Negotiable

Even minor deviations in the heating process can compromise the final product. The furnace directly impacts the restoration's accuracy of fit, material strength, and long-term clinical success. An improperly sintered crown can fail in the patient's mouth, damaging your lab's reputation.

How Neglected Maintenance Degrades Performance

Deferring maintenance introduces variables into a process that demands consistency. Each shortcut has a direct, negative consequence on the furnace's output.

Inconsistent Heating and Poor Outcomes

Dust accumulation or aging heating elements can create hot and cold spots within the firing chamber. This lack of temperature uniformity leads to incomplete or uneven sintering, resulting in weak spots, poor aesthetics, and restorations that do not meet clinical standards.

Compromised Structural Integrity

A well-maintained furnace manages gradual heating and cooling rates, which is critical for minimizing thermal stress on the zirconia. A malfunctioning system with faulty sensors or controls can heat or cool too quickly, causing microscopic cracks that lead to premature restoration failure.

Reduced Efficiency and Throughput

Features like multi-level stacking and fast-sintering programs rely on a perfectly functioning machine. A poorly maintained furnace is prone to errors, program failures, and inconsistent cycles, forcing technicians to run smaller batches or repeat work. This directly translates to lost productivity and revenue.

Understanding the Trade-offs: The Cost of Deferral

Skipping maintenance might seem like a way to save time and money in the short term, but it is one of the costliest financial and operational mistakes a lab can make.

Short-Term Savings vs. Catastrophic Failure

The cost of a preventative maintenance check is negligible compared to the cost of an emergency repair or, worse, a full furnace replacement. Deferring basic cleaning can lead to the failure of expensive components like heating elements or control boards.

The Hidden Cost of Downtime

When a furnace goes down, production stops. This means missed deadlines with your dental clients, delayed patient care, and a complete halt in a significant revenue stream. Unplanned downtime is exponentially more expensive than scheduled maintenance.

The Risk to Your Reputation

Delivering a single sub-par restoration that fails due to improper sintering can permanently damage a lab's relationship with a dental practice. The trust lost is far more valuable than any money saved by skipping maintenance.

Making the Right Choice for Your Lab

An effective maintenance routine is not a burden; it is a system for protecting your lab's core function. By focusing on your primary goal, the value becomes clear.

- If your primary focus is clinical quality: Regular maintenance is the only way to guarantee the consistent material strength, accurate fit, and reliable longevity your clients expect.

- If your primary focus is financial ROI: Proactive upkeep is the single best strategy to protect your furnace investment, prevent costly emergency repairs, and eliminate unplanned downtime.

- If your primary focus is operational efficiency: A well-maintained furnace ensures predictable cycle times, prevents failed batches, and maximizes your lab's daily throughput.

Ultimately, treating your sintering furnace with meticulous care is a direct investment in your lab's reputation for excellence.

Summary Table:

| Maintenance Aspect | Impact on Dental Lab |

|---|---|

| Consistent Heating | Ensures uniform sintering for strong, accurate restorations |

| Component Longevity | Maximizes furnace lifespan and reduces repair costs |

| Operational Reliability | Prevents unplanned downtime and maintains production efficiency |

| Quality Assurance | Guarantees clinical standards and protects lab reputation |

Ensure your dental lab's success with KINTEK's advanced sintering solutions. Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, with deep customization to meet your unique needs. Contact us today to enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab