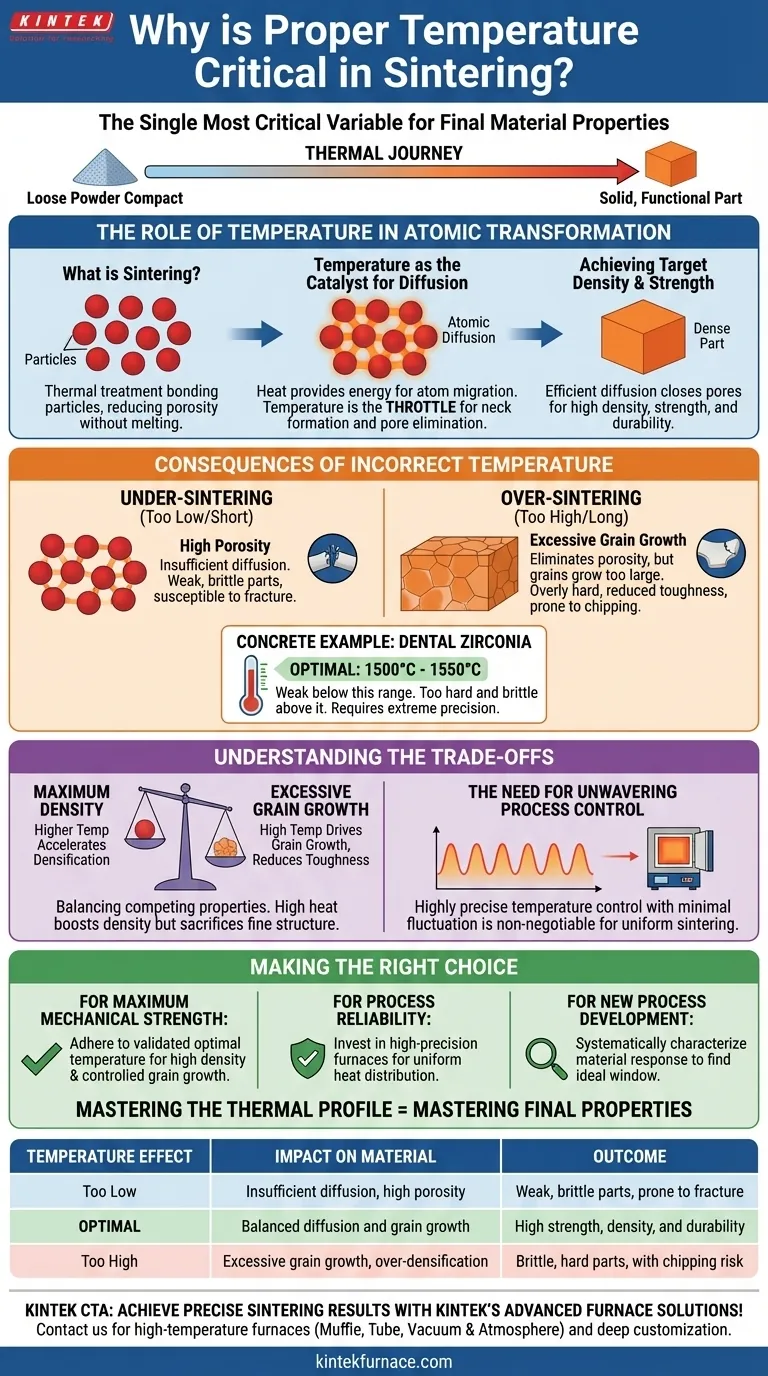

At its core, proper temperature in the sintering process is the single most critical variable that dictates the final material properties of a component. It directly controls the atomic-level bonding and densification that transforms a loose powder compact into a solid, functional part. An incorrect temperature, even by a small margin, can mean the difference between a high-performance component and a catastrophic failure.

Sintering is not simply a heating process; it is a precisely controlled thermal journey. The temperature determines the rate of atomic diffusion, which in turn defines the final microstructure—grain size and porosity—and therefore the ultimate strength, hardness, and durability of the finished product.

The Role of Temperature in Atomic Transformation

To understand why temperature is so crucial, you must first understand what is happening at a microscopic level during sintering.

What is Sintering?

Sintering is a thermal treatment that bonds individual particles of a powder together, reducing the empty space (porosity) between them. This is achieved without melting the material into a liquid state.

The goal is to create a dense, coherent solid with specific, desired mechanical and physical properties.

Temperature as the Catalyst for Diffusion

Heat provides the energy needed for atoms to move. As temperature rises, atoms at the contact points between particles begin to diffuse, or migrate, creating "necks" that bridge the gaps.

As the temperature is held, these necks grow wider, pulling the particles closer together and systematically eliminating the pores. Temperature is the throttle for this entire process.

Achieving Target Density and Strength

The primary objective of sintering is often to achieve maximum density. A higher density directly correlates with higher mechanical strength and durability.

Proper temperature ensures this diffusion process is efficient enough to close the vast majority of pores, resulting in a strong, solid part that performs as designed.

The Consequences of Incorrect Temperature

The window for the ideal sintering temperature is often narrow. Deviating from it introduces significant and predictable flaws.

Under-sintering: The Risk of Weakness

If the temperature is too low or the time at temperature is too short, atomic diffusion will be insufficient.

The result is a part with high residual porosity. These pores act as stress concentration points, making the final component weak, brittle, and highly susceptible to fracture under load.

Over-sintering: The Problem of Brittleness

Conversely, if the temperature is too high or the hold time is too long, the material can be over-sintered.

While this may eliminate porosity, it promotes excessive grain growth. Abnormally large grains can make the material overly hard and reduce its toughness, leading to chipping and cracking. This is a common failure mode in over-sintered ceramics.

A Concrete Example: Dental Zirconia

In the manufacturing of dental restorations, studies show that zirconia achieves its maximum strength when fired in a narrow range of 1500°C to 1550°C.

Below this range, the restoration is weak. Above it, it becomes too hard and prone to chipping, compromising its clinical performance. This highlights the need for extreme precision.

Understanding the Trade-offs

Achieving the "perfect" sintered part involves balancing competing properties, and temperature is the key to managing these trade-offs.

The Pursuit of Maximum Density

The primary goal is almost always to minimize porosity. Higher temperatures accelerate densification, which seems beneficial.

However, aggressively pursuing density with high heat can trigger other undesirable changes in the material's microstructure.

The Pitfall of Excessive Grain Growth

The most significant trade-off is between density and grain size. While high temperatures are good for density, they are also the primary driver of grain growth.

A material with a fine, uniform grain structure is typically tougher and more resistant to fracture than a material with large, coarse grains. Over-sintering sacrifices this fine structure, creating a dense but brittle part.

The Need for Unwavering Process Control

Because of this delicate balance, process control is non-negotiable. The sintering furnace must have a highly precise temperature control system with minimal fluctuation.

Even, stable heat is required to ensure that the entire part sinters uniformly, hitting the sweet spot that maximizes density while controlling grain growth.

Making the Right Choice for Your Goal

Your approach to temperature control should be dictated by your end goal. Use these principles as your guide.

- If your primary focus is maximum mechanical strength: Identify and adhere to the validated optimal temperature for your specific material, which balances high density with controlled, uniform grain growth.

- If your primary focus is process reliability and consistency: Invest in high-precision furnaces that guarantee minimal temperature fluctuations and uniform heat distribution across the entire part.

- If you are developing a new process: Systematically characterize your material's response to a range of temperatures to empirically discover its ideal sintering window, rather than relying on generic guidelines.

Ultimately, mastering the thermal profile is equivalent to mastering the final properties of your material.

Summary Table:

| Temperature Effect | Impact on Material | Outcome |

|---|---|---|

| Too Low | Insufficient diffusion, high porosity | Weak, brittle parts prone to fracture |

| Optimal | Balanced diffusion and grain growth | High strength, density, and durability |

| Too High | Excessive grain growth, over-densification | Brittle, hard parts with chipping risk |

Achieve precise sintering results with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met for superior material properties. Contact us today to discuss how we can enhance your sintering process and deliver reliable, high-performance outcomes!

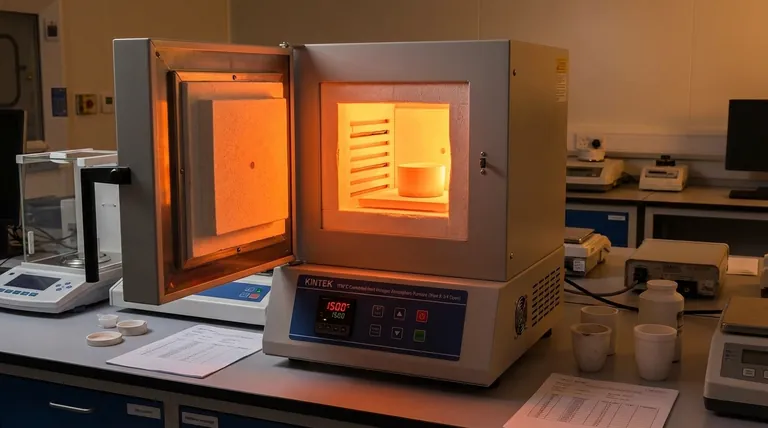

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials