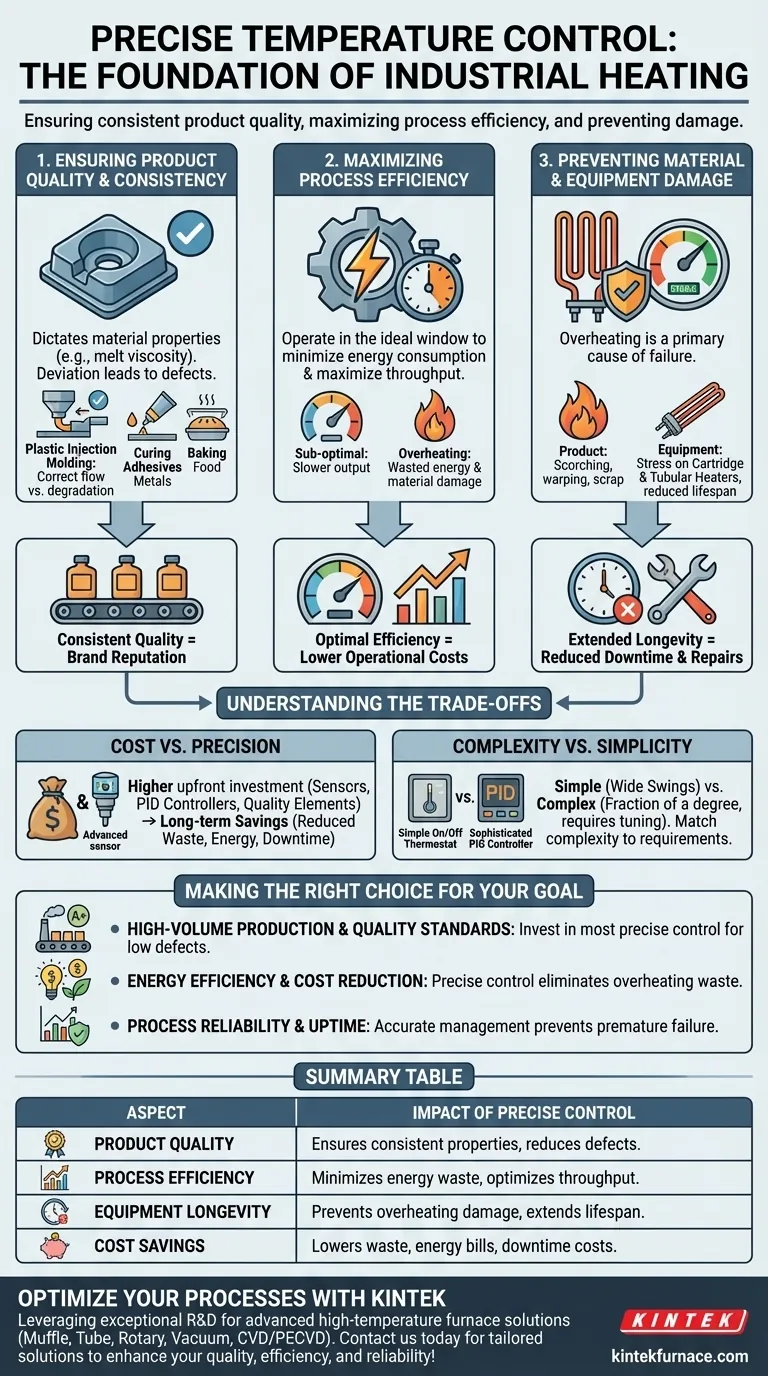

In short, precise temperature control is essential in industrial heating for three primary reasons: ensuring consistent product quality, maximizing process efficiency, and preventing damage to both materials and equipment. Inaccurate temperature leads directly to defects, wasted energy, and costly operational failures.

Temperature is not just a setting; it is a critical process variable that dictates the outcome of your entire operation. The difference between precise control and "close enough" is the difference between profitability and perpetual troubleshooting.

The Core Pillars of Temperature Control

To understand its importance, we must view temperature control not as an isolated task but as a foundational element impacting every stage of production.

Ensuring Product Quality and Consistency

For many materials, temperature dictates their physical and chemical properties. A deviation of just a few degrees can be the difference between a perfect product and a useless one.

In processes like plastic injection molding, for example, precise temperature ensures the correct melt viscosity. Too cool, and the plastic won't flow properly into the mold; too hot, and the material can degrade, compromising its structural integrity.

This principle applies across industries, from curing adhesives and annealing metals to baking food products. Consistency in temperature ensures every single unit meets the exact same quality specifications.

Maximizing Process Efficiency

Operating at the optimal temperature is key to minimizing energy consumption and maximizing throughput.

Processes run slower at sub-optimal temperatures, reducing output. Conversely, overheating a process to speed it up often wastes enormous amounts of energy and introduces the risk of material damage, creating a net loss in efficiency.

Precise control allows you to operate in the narrow, ideal temperature window, ensuring you use the minimum energy required to achieve the desired result in the shortest possible time.

Preventing Material and Equipment Damage

Overheating is a primary cause of failure for both the product and the production machinery.

For the product, excessive heat can cause scorching, warping, or chemical decomposition, rendering it scrap. For the equipment, it places extreme stress on components like cartridge heaters and tubular heating elements, drastically shortening their operational lifespan.

This leads to unplanned downtime, expensive repairs, and replacement costs—all of which are easily avoided with a well-regulated heating system.

Understanding the Trade-offs

While the benefits are clear, implementing high-precision systems involves balancing competing priorities.

Cost vs. Precision

Higher precision requires an upfront investment. This includes more accurate sensors (like RTDs or thermocouples), advanced PID (Proportional-Integral-Derivative) controllers, and higher-quality heating elements designed for uniform heat distribution.

While the initial cost is higher, it is almost always offset by long-term savings from reduced material waste, lower energy bills, and less equipment downtime.

Complexity vs. Simplicity

A simple on/off thermostat is easy to implement but creates wide temperature swings. A sophisticated PID controller, on the other hand, can hold a temperature within a fraction of a degree but requires proper tuning and sensor placement.

The key is to match the level of complexity to the process requirements. A non-critical warming application may not need PID control, but a medical device manufacturing line certainly does.

Making the Right Choice for Your Goal

Your specific objective will determine how you prioritize temperature control in your system design.

- If your primary focus is high-volume production with strict quality standards: Investing in the most precise control system available is non-negotiable to minimize defect rates and ensure brand reputation.

- If your primary focus is energy efficiency and cost reduction: Precise control allows you to eliminate energy waste from overheating and run your process at its most efficient setpoint.

- If your primary focus is process reliability and uptime: Accurate temperature management is your best defense against the premature failure of heating elements and other critical components.

Ultimately, precise temperature control transforms a heating element from a simple component into a strategic asset for process optimization.

Summary Table:

| Aspect | Impact of Precise Temperature Control |

|---|---|

| Product Quality | Ensures consistent material properties and reduces defects |

| Process Efficiency | Minimizes energy waste and optimizes throughput |

| Equipment Longevity | Prevents overheating damage and extends lifespan |

| Cost Savings | Lowers waste, energy bills, and downtime costs |

Ready to optimize your industrial processes with precise temperature control? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your quality, efficiency, and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment