At its core, the durability and build quality of a porcelain furnace are paramount because they directly determine the consistency of your restorations, the safety of your lab, and the long-term return on your investment. A well-built furnace is not a luxury; it is the foundation for predictable clinical outcomes, designed to repeatedly withstand extreme temperatures and pressures without failure.

A porcelain furnace is more than just a heating appliance—it is a precision instrument. Investing in superior build quality is an investment in the foundational pillars of any successful dental lab: the consistency of the final product, the safety of the operator, and the profitability of the operation.

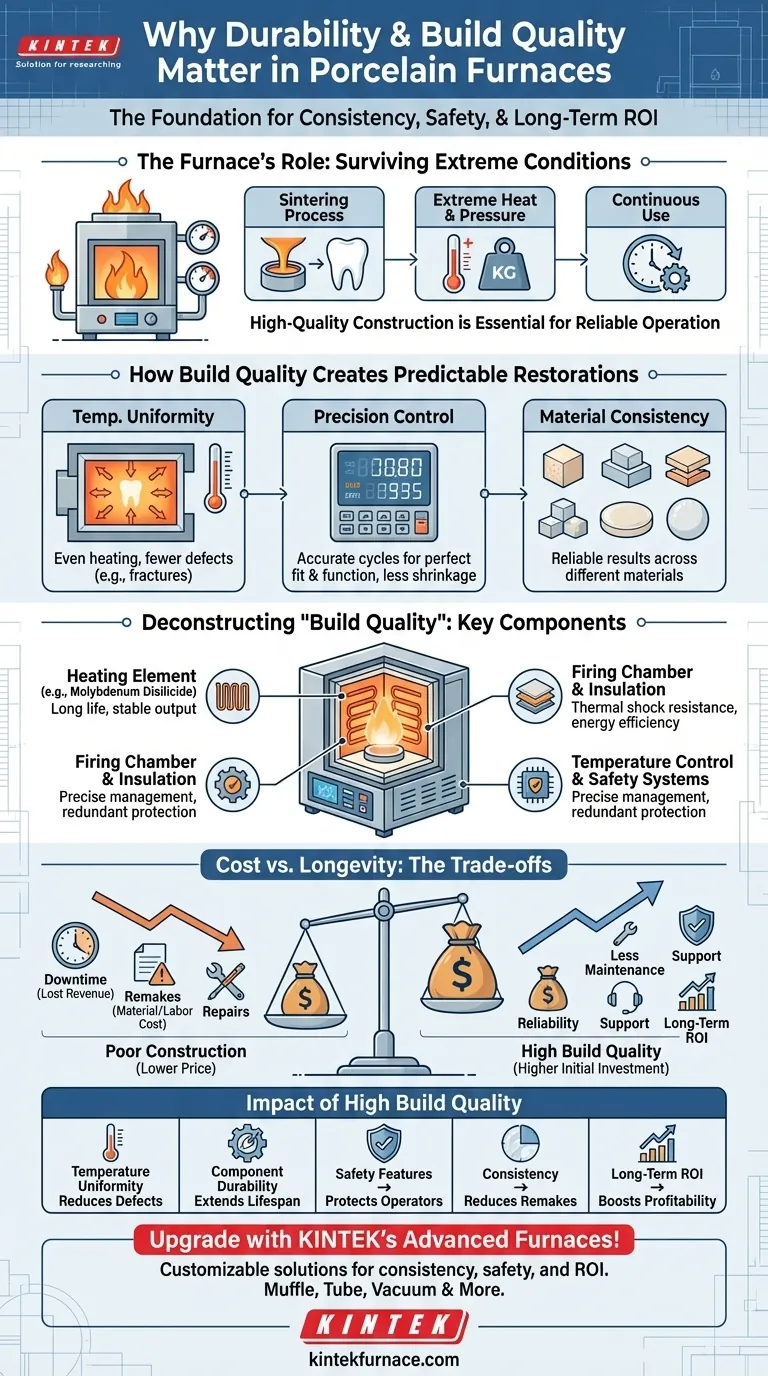

The Furnace's Role: Surviving Extreme Conditions

A porcelain furnace's primary job is to execute a controlled process of extreme heating and cooling. This process, known as sintering, transforms shaped ceramic particles into a hard, dense, and precisely dimensioned final restoration.

Withstanding Immense Heat and Pressure

The furnace must reliably reach and maintain very high temperatures, often under vacuum, to fuse ceramic materials correctly. Inferior materials in the furnace's construction can degrade, warp, or fail under this thermal stress, leading to immediate operational failure.

The Demands of Continuous Use

In a productive lab, a furnace runs continuously throughout the day. High-quality construction, from the casing to the internal wiring, ensures the unit can handle this demanding duty cycle without frequent breakdowns, which cause costly downtime and disrupt workflow.

How Build Quality Creates Predictable Restorations

The ultimate goal of any firing cycle is a perfectly fitted, aesthetically pleasing restoration. The physical construction of the furnace is what makes this achievable time after time.

The Critical Role of Temperature Uniformity

A well-built furnace with high-quality insulation and premium heating elements ensures even temperature distribution throughout the firing chamber. Poor uniformity, a common flaw in lower-quality units, creates hot and cold spots, leading to uneven sintering, stress fractures, and defects in the final restoration.

Precision Control for Dimensional Accuracy

The final fit and function of a crown or bridge depend on achieving precise dimensions during sintering. A durable furnace with a high-quality temperature controller and thermocouple (measuring element) can execute programmed firing cycles with extreme accuracy. This precision prevents shrinkage or expansion issues, minimizing the need for remakes.

Consistency Across Materials

Modern dental labs use a wide array of ceramic materials, each with a unique and specific firing protocol. A robust, well-constructed furnace provides a stable platform that can be programmed to handle these different requirements reliably, ensuring consistent results no matter the material.

Deconstructing "Build Quality": Key Components to Scrutinize

"Build quality" is not an abstract concept. It can be observed in the specific components that make up the furnace.

The Heating Element

This is the heart of the furnace. High-grade elements, often made of molybdenum disilicide, are designed for a long service life and stable temperature output. Cheaper elements are prone to faster degradation and can cause temperature fluctuations that ruin restorations.

The Firing Chamber and Insulation

The chamber must be made of a durable refractory material that resists thermal shock. The quality of the surrounding insulation directly impacts temperature uniformity and energy efficiency. Poor insulation leads to heat loss, inconsistent firing, and higher energy bills.

Temperature Control and Safety Systems

The electronic controller and its associated sensors are the brains of the operation. A quality system provides precise temperature management and includes redundant safety features to protect against overheating. This is not only for protecting the restoration but also for ensuring the safety of the lab environment.

Understanding the Trade-offs: Cost vs. Longevity

While a well-built furnace carries a higher initial price, a cheaper alternative often introduces significant hidden costs.

The Hidden Costs of Poor Construction

A furnace built with inferior components is more likely to fail. These failures result in lost revenue from downtime, the material and labor costs of remaking cases, and damage to your lab's reputation for quality and reliability.

Maintenance and Support

Manufacturers of high-quality equipment typically provide better technical support and easier access to replacement parts. Investing in a durable unit from a reputable brand ensures you have a partner in maintaining your equipment for the long term.

Making the Right Choice for Your Goal

When evaluating a porcelain furnace, your decision should align with your lab's primary objectives.

- If your primary focus is clinical quality: Prioritize a furnace with documented temperature uniformity and a high-precision digital control system.

- If your primary focus is long-term ROI: Invest in a unit with robust chamber construction, premium heating elements, and a strong manufacturer warranty.

- If your primary focus is operational safety: Ensure the furnace has certified safety features, high-quality insulation, and a reliable temperature protection system.

Ultimately, choosing a furnace based on its durability and build quality is an investment in predictable outcomes and the long-term success of your practice.

Summary Table:

| Aspect | Impact of High Build Quality |

|---|---|

| Temperature Uniformity | Ensures even heating, reduces defects like stress fractures |

| Component Durability | Extends lifespan, minimizes breakdowns and maintenance costs |

| Safety Features | Protects operators and prevents overheating incidents |

| Consistency Across Materials | Reliable results with various ceramics, reducing remakes |

| Long-Term ROI | Lowers hidden costs from downtime and remakes, boosts profitability |

Upgrade your dental lab with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your unique experimental needs are met, enhancing restoration consistency, safety, and ROI. Contact us today to discuss how our durable, high-quality furnaces can transform your operations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations