At its core, a zirconia sintering furnace is the essential final step in the digital dental workflow, transforming a soft, milled zirconia blank into a final restoration with the strength and durability required for clinical success. Without this controlled heating process, modern zirconia crowns, bridges, and implants would simply not be possible.

The furnace is not merely a heater; it is a precision instrument that guarantees the final physical properties of a dental restoration. It ensures the bridge between a digital design and a clinically reliable, high-strength ceramic prosthetic is successfully crossed.

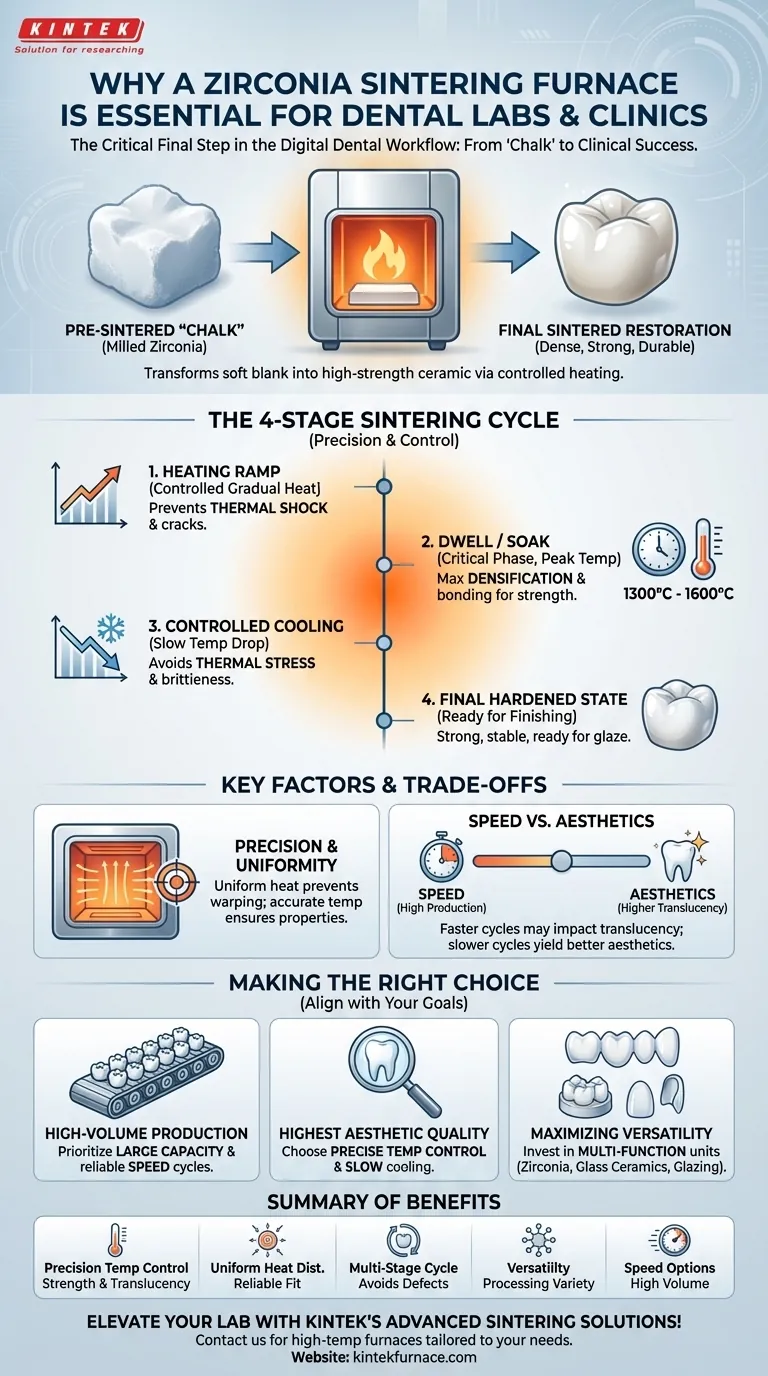

The Critical Transformation: From "Chalk" to Ceramic

A zirconia sintering furnace executes a highly controlled process of densification. It takes a pre-sintered, chalk-like zirconia structure and transforms it into a dense, non-porous, and incredibly strong final restoration.

What is Zirconia Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction.

In dentistry, this means heating the milled zirconia until its individual ceramic particles bond together, eliminating the voids between them and shrinking the restoration to its final, dense size.

The Role of Precision Heating

The furnace's primary job is to heat the zirconia to a specific, high temperature, typically between 1300°C and 1600°C.

This temperature must be reached and held with extreme accuracy. Different types of zirconia require different temperature profiles to achieve their optimal translucency and strength.

Why Uniform Heat is Non-Negotiable

The computerized furnace ensures heat is distributed uniformly throughout the chamber.

Uneven heating can cause internal stresses, warping, or incomplete sintering in parts of the restoration, compromising its structural integrity and clinical fit.

The Four Stages of a Successful Sintering Cycle

The value of a sintering furnace lies in its ability to manage a precise, multi-stage thermal cycle automatically, ensuring predictable results with minimal operator intervention.

Stage 1: The Heating Ramp

The furnace does not instantly jump to its peak temperature. It follows a controlled, gradual heating ramp.

This slow increase prevents thermal shock, which could cause cracks or fractures in the delicate pre-sintered material.

Stage 2: The Dwell or "Soak"

Once at peak temperature, the furnace "dwells" or "soaks" for a prescribed period. This is the most critical phase.

During the dwell, the ceramic particles fully bond and the material achieves maximum densification, which is directly responsible for its final strength.

Stage 3: Controlled Cooling

Just as important as the heating ramp is the controlled cooling phase.

Rapid cooling would again introduce thermal stress, making the final restoration brittle. The furnace slowly lowers the temperature to ensure a stress-free, stable final product.

Stage 4: The Final Hardened State

After the cycle is complete and the restoration has cooled, it is removed from the furnace.

The result is a restoration that is incredibly strong, durable, and ready for final staining, glazing, and polishing before delivery to the patient.

Understanding the Trade-offs and Common Pitfalls

While essential, the choice of furnace and sintering cycle involves balancing competing priorities. Understanding these trade-offs is key to mastering the technology.

Speed vs. Aesthetics

Many modern furnaces offer "speed" sintering cycles that can be completed in a fraction of the time of a conventional cycle.

While highly efficient for production, these faster cycles can sometimes impact the final translucency and aesthetic properties of the zirconia. Slower, longer cycles generally yield the most aesthetically pleasing results.

The Need for Versatility

A furnace is a significant investment. Many modern units are designed for more than just zirconia.

The ability to also process glass ceramics or perform glazing cycles adds significant value and versatility to a dental lab, maximizing the return on investment.

The Risk of Contamination

A clean furnace environment is critical for predictable results. Contamination from other materials or improper cleaning can discolor zirconia restorations or interfere with the sintering process.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the primary goals of your laboratory or clinic. The technology empowers you to deliver high-quality restorations, but the specific model should align with your business needs.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber capacity and proven, reliable speed sintering cycles.

- If your primary focus is the highest aesthetic quality: Choose a furnace known for its precise temperature control and programmable, slow-cooling options.

- If your primary focus is maximizing versatility: Invest in a multi-function furnace certified for sintering zirconia, firing glass ceramics, and glazing.

Ultimately, integrating a quality zirconia sintering furnace is a foundational step for any practice committed to providing modern, durable, and reliable ceramic restorations.

Summary Table:

| Feature | Benefit |

|---|---|

| Precision Temperature Control | Ensures optimal strength and translucency of zirconia restorations |

| Uniform Heat Distribution | Prevents warping and internal stresses for reliable clinical fit |

| Multi-Stage Sintering Cycle | Manages heating, dwell, and cooling to avoid thermal shock and brittleness |

| Versatility for Multiple Materials | Allows processing of zirconia, glass ceramics, and glazing for ROI |

| Speed and Efficiency Options | Supports high-volume production with customizable sintering cycles |

Elevate your dental laboratory with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide dental labs and clinics with high-temperature furnaces tailored for zirconia sintering, glass ceramics, and more. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how our furnaces can enhance your workflow, improve restoration quality, and boost efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations