In modern dental ceramics, the vacuum pump is not an optional accessory; it is a core component for achieving clinical and aesthetic success. Its primary function is to evacuate air from the firing chamber at a critical stage in the heating process. This single action is directly responsible for preventing the formation of bubbles and voids within the porcelain, which would otherwise result in a weak, porous, and unacceptably opaque final restoration.

The fundamental challenge in firing porcelain is fusing countless tiny particles into a single, dense, and translucent solid. A vacuum pump makes this possible by removing the atmospheric gases that would otherwise become trapped during fusion, ensuring the final material possesses the strength and light-handling properties of a natural tooth.

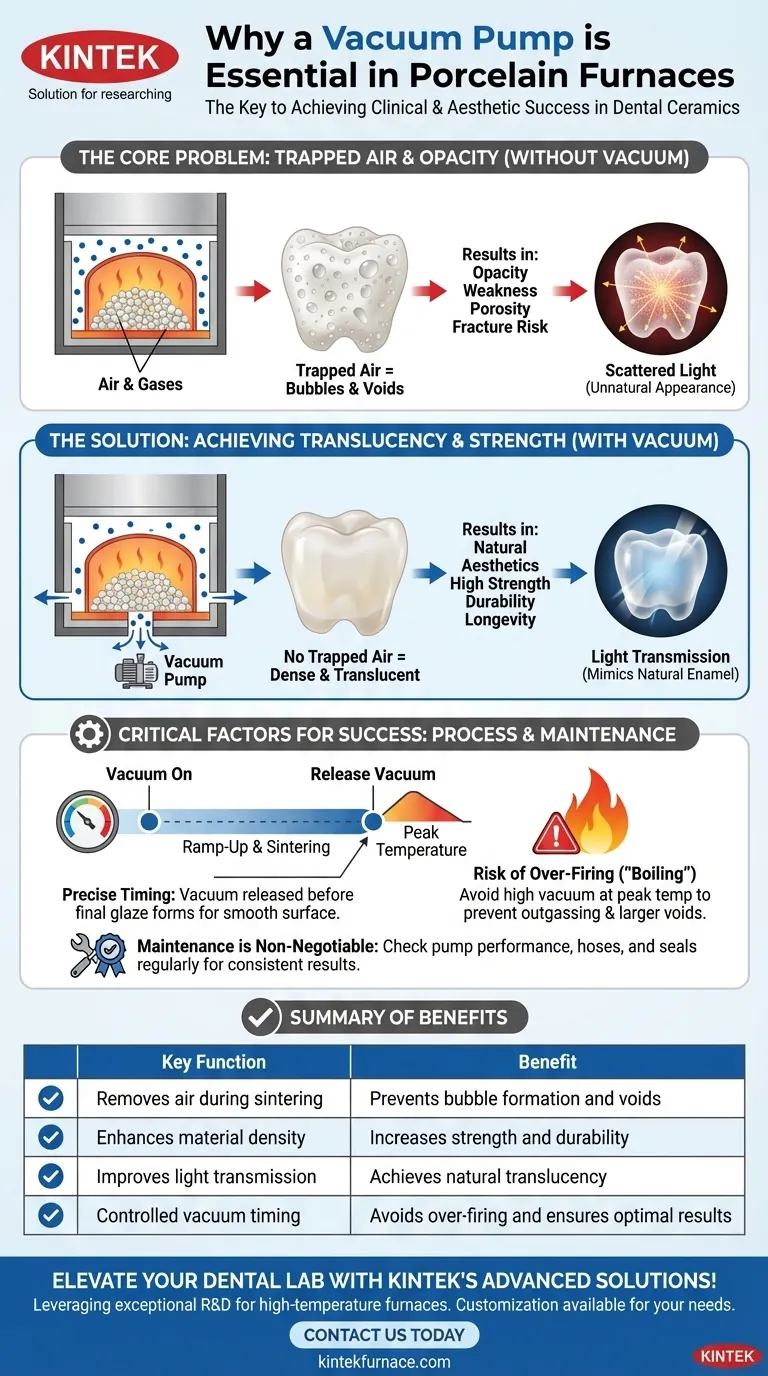

The Core Problem: Trapped Air During Sintering

To understand the role of the vacuum, you must first understand the physics of what happens inside the furnace when you are not using one. The goal of firing is to transform loose powder into a solid, vitrified mass.

What Happens When Porcelain is Fired?

The process of firing porcelain is called sintering. During sintering, individual porcelain particles are heated until their surfaces begin to soften and fuse together.

As the temperature rises, these particles bond, eliminating the spaces between them and densifying the material into a strong, glass-like structure.

The Undesirable Role of Air

A furnace chamber is initially filled with ambient air, which is composed primarily of nitrogen and oxygen. As the porcelain particles begin to fuse, this air becomes trapped in the microscopic pockets between them.

Because the outer surface of the porcelain fuses and seals first, these trapped gases have no path to escape.

The Formation of Voids and Opacity

These pockets of trapped gas become permanent voids or bubbles within the fired porcelain. Each tiny bubble acts as a disruption, scattering light that enters the material instead of allowing it to pass through.

The cumulative effect of millions of these micro-bubbles is opacity—the milky, chalky appearance that signifies a low-quality restoration. Furthermore, these voids are points of weakness, creating a porous structure that is much more susceptible to fracture.

How the Vacuum Pump Provides the Solution

The vacuum pump directly counteracts the problem of trapped air by creating a controlled, low-pressure environment at the most critical moment.

Removing Air Before It Becomes Trapped

The furnace program engages the vacuum pump during the temperature ramp-up, well before the porcelain reaches its vitrification (glossing) point.

By evacuating the vast majority of air molecules from the chamber, there is simply no gas left to become entrapped as the porcelain particles begin to fuse.

Ensuring Translucency and Natural Aesthetics

The primary and most visible benefit is a dramatic increase in translucency. Without bubbles to scatter light, the fired porcelain allows light to penetrate and reflect in a manner that closely mimics natural tooth enamel.

This is the key to creating restorations that blend seamlessly and avoid a "fake" or lifeless appearance.

Enhancing Structural Integrity and Density

Beyond aesthetics, removing voids creates a significantly denser and more robust material. Voids act as stress concentrators, where cracks are likely to initiate under chewing forces.

Vacuum-fired porcelain is less porous, stronger, and far more durable over the long term, reducing the risk of clinical failure.

Understanding the Process and Its Trade-offs

Simply having a vacuum pump is not enough; its use must be precisely controlled to achieve the desired outcome. Incorrect application can create its own set of problems.

The Importance of Vacuum Timing

A typical firing program does not hold a vacuum for the entire cycle. The vacuum is applied during the heat-up and sintering phase but is often released before the peak temperature is reached.

Breaking the vacuum allows the final glaze to form under normal atmospheric pressure, which helps create a smooth, non-porous surface texture.

The Risk of Over-Firing or "Boiling"

If a very high vacuum is held at the peak temperature for too long, it can cause certain volatile elements within the porcelain itself to outgas, or "boil." This can paradoxically create larger, more destructive voids.

This is why following the porcelain manufacturer's recommended firing schedules is critical. These programs are designed to balance vacuum application with temperature for optimal results.

Maintenance is Non-Negotiable

A weak or failing vacuum pump is a common source of frustrating and inconsistent results. If the pump cannot achieve the required vacuum level (typically measured in inches of mercury or millibars), a small amount of air will remain, leading to milky or opaque restorations.

Regular maintenance of the pump, hoses, and furnace door seals is essential for predictable, high-quality work.

Applying This Knowledge for Consistent Results

Understanding the "why" behind vacuum firing empowers you to troubleshoot issues and achieve predictable excellence with your ceramic restorations.

- If your primary focus is aesthetics and translucency: A properly functioning vacuum system is your most important tool for preventing the micro-bubbles that cause opacity and cloudiness.

- If your primary focus is strength and longevity: Eliminating voids through vacuum firing is essential for creating a dense, non-porous restoration that resists fracture under load.

- If you are experiencing inconsistent results (e.g., milky porcelain): Your first diagnostic step should be to verify the performance of your vacuum pump and check the integrity of the furnace's seals.

Ultimately, the vacuum pump transforms the firing process from simple heating into a controlled atmospheric event, which is the key to producing professional-grade porcelain restorations.

Summary Table:

| Key Function | Benefit |

|---|---|

| Removes air during sintering | Prevents bubble formation and voids |

| Enhances material density | Increases strength and durability |

| Improves light transmission | Achieves natural translucency |

| Controlled vacuum timing | Avoids over-firing and ensures optimal results |

Elevate your dental lab's ceramic restorations with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering reliable performance and superior results. Contact us today to discuss how we can enhance your workflow and product quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations