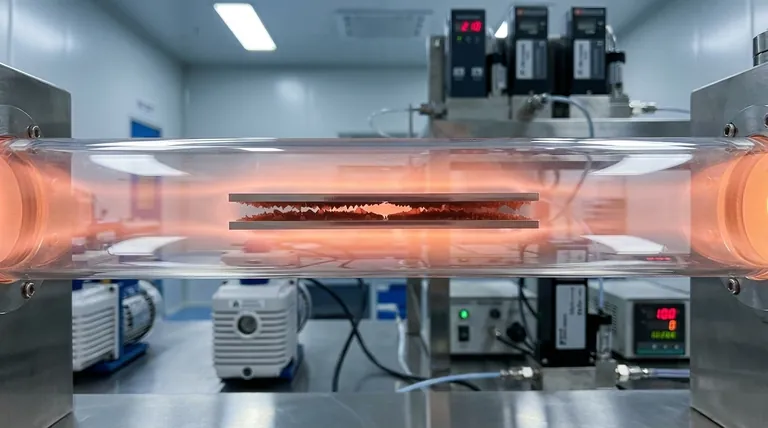

Space-confined growth is utilized in the Chemical Vapor Deposition (CVD) of epsilon-Fe2O3 to mechanically and chemically force the material into a specific geometric configuration. By creating a quasi-static local chemical environment within a micro-sized space, this arrangement drives the material to grow outward rather than upward, resulting in superior thin-film uniformity.

Core Insight: By stacking substrates face-to-face, the process equalizes reactant partial pressure and suppresses rapid vertical growth. This mechanism is the key to transforming non-layered epsilon-Fe2O3 into large-dimension, ultra-thin nanosheets with precise thickness control.

The Mechanics of the Micro-Environment

Creating a Quasi-Static Zone

The space-confined arrangement is typically achieved by stacking two substrates face-to-face.

This configuration creates a restricted micro-sized gap between the surfaces. Within this gap, the gas flow dynamics shift from turbulent or fast-flowing to a quasi-static state, stabilizing the local chemical atmosphere.

Uniformity of Partial Pressure

In a standard open-flow CVD setup, reactant concentration can vary significantly across the substrate.

The confined space ensures a highly uniform reactant partial pressure. This uniformity guarantees that the chemical potential driving the growth is consistent across the entire deposition area, reducing defects caused by concentration gradients.

Controlling Grain Geometry

Promoting Lateral Expansion

The primary goal of this arrangement is to influence the direction of crystal growth.

The specific partial pressure conditions within the confined space promote the lateral expansion of the epsilon-Fe2O3 grains. This encourages the material to spread out horizontally, effectively creating a 2D structure out of a material that is naturally non-layered.

Inhibiting 3D Stacking

Without space confinement, crystals tend to pile up on top of one another.

This arrangement specifically inhibits rapid three-dimensional stacking. By suppressing vertical growth, the method prevents the formation of thick, irregular clusters and instead favors the formation of smooth, continuous nanosheets.

Understanding the Trade-offs

Diffusion Limitations

While creating a quasi-static environment improves uniformity, it changes the mass transport mechanism.

Reactants must diffuse into the confined space, which can potentially limit the deposition rate compared to direct-flow methods. The process prioritizes crystallographic quality and geometry over raw deposition speed.

Complexity of Setup

Implementing a face-to-face stacking arrangement adds a mechanical variable to the CVD process.

Ensuring the gap remains consistent and the substrates are perfectly aligned is critical. Any variation in the spacing could lead to gradients in film thickness, negating the benefits of the confinement.

Making the Right Choice for Your Goal

To determine if this growth arrangement suits your specific fabrication needs, consider the following:

- If your primary focus is high-aspect-ratio nanosheets: This method is essential, as it forces lateral growth and inhibits vertical accumulation.

- If your primary focus is precise thickness control: The quasi-static environment offers a more stable kinetic regime for tuning ultra-thin dimensions.

The geometry of the reaction space is just as critical as temperature and gas flow in defining the final morphology of your thin film.

Summary Table:

| Feature | Standard CVD Arrangement | Space-Confined CVD Arrangement |

|---|---|---|

| Growth Direction | Rapid 3D / Vertical Stacking | Lateral / Horizontal Expansion |

| Gas Dynamics | Turbulent / Fast-Flowing | Quasi-Static Micro-Environment |

| Partial Pressure | Variable Gradient | Uniform Distribution |

| Morphology | Irregular Clusters / Thick Films | Ultra-Thin, Smooth Nanosheets |

| Primary Priority | Deposition Speed | Crystallographic Quality & Geometry |

Elevate Your Thin-Film Research with KINTEK

Precision in epsilon-Fe2O3 synthesis requires more than just chemistry; it requires the right thermal and atmospheric control. At KINTEK, we specialize in the engineering of high-performance CVD systems designed to meet the rigorous demands of space-confined growth.

Our value to you:

- Customizable Solutions: From Muffle and Tube furnaces to specialized Vacuum and CVD systems, our equipment is tailored to your specific research needs.

- Expert R&D Support: Leverage our manufacturing expertise to achieve perfect reactant partial pressure and thermal uniformity.

- Precision Control: Our systems empower you to master lateral grain expansion and inhibit 3D stacking for superior nanosheet quality.

Ready to transform your material fabrication? Contact KINTEK today to discuss how our lab high-temperature furnaces can optimize your next breakthrough.

Visual Guide

References

- Wuhong Xue, Xiaohong Xu. Stable antivortices in multiferroic ε-Fe2O3 with the coalescence of misaligned grains. DOI: 10.1038/s41467-025-55841-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does precise gas flow control affect Cr2O3 thin films? Mastering Stoichiometry and Crystal Structure

- How does a Mass Flow Controller influence 2D superlattices? Precision CVD Control for Sub-10nm Patterning

- Why is gas flow distribution critical in LPCVD alpha-MnSe synthesis? Master Precise Nanosheet Morphology

- What types of surface coatings can be applied using CVD furnaces? Discover Versatile Solutions for Your Needs

- How does the CVD process work in depositing materials onto substrates? Master Thin-Film Deposition for Superior Materials

- Why is a high-precision gas mass flow control system necessary for Ga2O3 growth? Achieve Defect-Free Thin Films

- What is a CVD used for? Engineer High-Performance Thin Films for Advanced Applications

- What advanced control features are available in CVD furnaces? Unlock Precision and Reproducibility