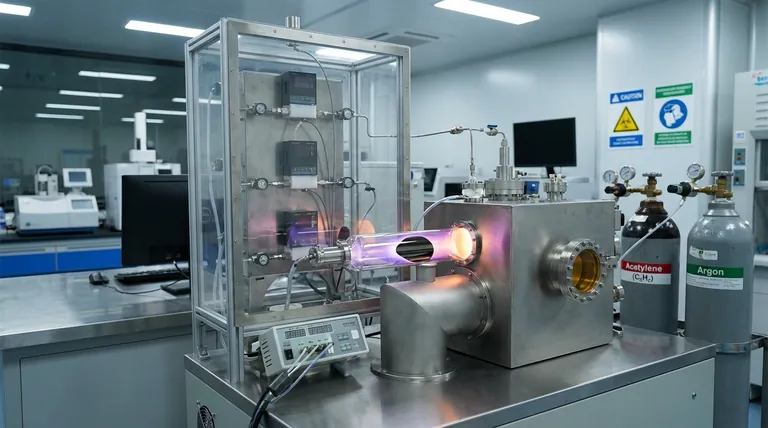

The combination of high-purity graphite targets and acetylene gas is utilized to create a hybrid deposition environment that offers superior control over the coating's atomic structure. This dual approach allows engineers to precisely adjust the ratio of sp2 to sp3 hybridized carbon atoms, which directly dictates the functional performance of the Diamond-Like Carbon (DLC) layer.

By integrating physical sputtering with chemical vapor deposition elements, this process enables the production of an amorphous carbon film that balances high hardness with low friction and excellent chemical inertness.

The Roles of the Components

Graphite: The Physical Carbon Source

High-purity graphite targets serve as the foundational material for the coating. Through a process known as sputtering, carbon atoms are physically ejected from these targets to build the bulk of the film.

Acetylene: The Chemical Regulator

Acetylene (C2H2) gas is introduced into the system via Chemical Vapor Deposition (CVD) components. While it contributes carbon, its primary function is regulatory.

The presence of acetylene helps control the internal structure of the coating. It creates a mechanism to fine-tune the film's properties beyond what simple sputtering could achieve alone.

Controlling the Microstructure

Tuning the sp2/sp3 Ratio

The defining characteristic of a DLC coating is its hybridization ratio. This is the balance between sp2 (graphite-like) and sp3 (diamond-like) carbon bonds.

Using both graphite and acetylene allows for the precise adjustment of this ratio. The operator can dial in the specific mixture to favor the desired characteristics of the final layer.

Resulting Physical Properties

When this ratio is optimized, the result is an amorphous carbon film.

This specific structure provides a low friction coefficient, essential for reducing wear in moving parts. Simultaneously, it maintains high hardness, protecting the substrate from abrasive damage.

Critical Trade-offs to Consider

Process Sensitivity

The primary challenge of this hybrid method is the requirement for precise adjustment. Because the properties rely on a specific ratio of gases and sputtered material, the process window can be narrow.

Balancing Hardness and Toughness

While high hardness is often the goal, a coating that is too hard can be brittle.

The introduction of acetylene helps regulate toughness. Deviating from the optimal gas flow could disrupt this balance, resulting in a coating that is either too soft (lacking durability) or too brittle (prone to cracking).

Making the Right Choice for Your Goal

This hybrid deposition method is best suited for applications requiring a specific "recipe" of physical properties.

- If your primary focus is Wear Resistance: Ensure the process parameters prioritize a higher sp3 ratio to maximize hardness.

- If your primary focus is Component Longevity: Focus on the acetylene regulation to optimize toughness and chemical inertness to prevent environmental degradation.

The synergy between graphite targets and acetylene gas turns a simple coating process into a tunable engineering solution for high-performance surfaces.

Summary Table:

| Component | Role in DLC Deposition | Primary Benefit |

|---|---|---|

| High-Purity Graphite | Physical Sputtering Source | Provides bulk carbon for film growth |

| Acetylene (C2H2) | Chemical Vapor Regulator | Fine-tunes sp2/sp3 ratio and toughness |

| Hybrid Process | Synergistic Deposition | Balances extreme hardness with low friction |

Elevate Your Material Performance with KINTEK Precision

Unlock the full potential of your Diamond-Like Carbon coatings with our specialized deposition technology. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique thin-film and heat-treatment requirements.

Whether you are optimizing for wear resistance or component longevity, our systems provide the precise control needed for professional-grade results. Contact our specialists today to find the perfect solution for your lab or production facility!

References

- Eneko Barba, J.A. Garcı́a. Study of the Industrial Application of Diamond-Like Carbon Coatings Deposited on Advanced Tool Steels. DOI: 10.3390/coatings14020159

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does PECVD benefit heat-sensitive substrates? Enable Low-Temperature Film Deposition

- What are the characteristics of a single wafer PECVD chamber? Optimize Thin Film Deposition for Your Lab

- What is the typical setup for PECVD in terms of chamber and electrode configuration? Optimize Thin Film Deposition

- Which industries commonly use PECVD coatings? Unlock Advanced Thin-Film Solutions for Your Sector

- What makes amorphous silicon (a-Si) suitable for thin-film applications? Economical, Flexible, and Scalable Solutions

- What are the origins of PECVD? Discover the Low-Temperature Breakthrough in Thin-Film Deposition

- Why is PECVD preferred for thermally sensitive substrates? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the key advantages of PECVD over traditional methods? Unlock Low-Temperature Thin Film Deposition