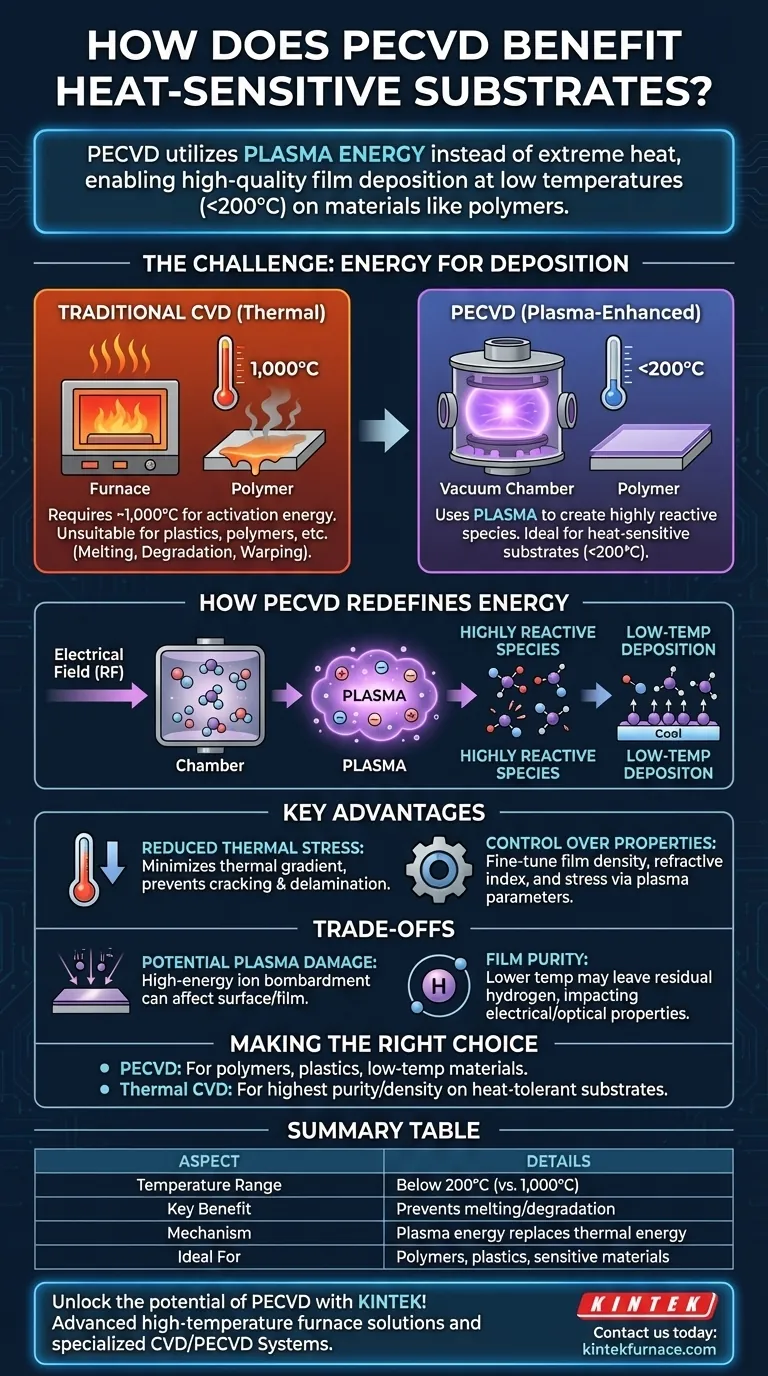

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) benefits heat-sensitive substrates by fundamentally changing how deposition energy is supplied. Instead of relying on extreme heat like traditional Chemical Vapor Deposition (CVD), which operates around 1,000°C, PECVD uses plasma to drive chemical reactions at much lower temperatures, often below 200°C. This allows for high-quality film deposition on materials like polymers that would otherwise melt, degrade, or warp.

The critical advantage of PECVD is not just its lower operating temperature, but its ability to substitute raw thermal energy with plasma energy. This creates the necessary chemical reactivity for film deposition without subjecting the substrate to destructive levels of heat.

The Challenge: Energy for Deposition

Why Traditional CVD Requires High Heat

Chemical Vapor Deposition is a process where volatile precursor gases react or decompose on a substrate surface to produce a solid thin film.

For these chemical reactions to occur, a significant amount of activation energy is required. In traditional thermal CVD, this energy is supplied entirely by heating the substrate to very high temperatures, often approaching 1,000°C.

The Problem for Sensitive Substrates

This extreme heat makes thermal CVD completely unsuitable for a wide range of materials. Substrates like plastics, polymers, and certain metals or glasses cannot withstand such temperatures without being physically damaged or destroyed.

How PECVD Redefines the Energy Source

Substituting Heat with Plasma

PECVD technology circumvents the need for high heat by introducing a different form of energy. Inside the PECVD chamber, an electrical field (typically a radio-frequency glow discharge) is applied to the precursor gases.

This electrical energy ionizes the gas, transforming it into plasma—a highly energetic state of matter containing ions, electrons, and reactive neutral species.

Creating Highly Reactive Species

The key to the process is that the energy within the plasma is sufficient to break down the precursor gas molecules into highly reactive ions and radicals.

These reactive species are chemically "primed" to form a film. They require far less thermal energy to react and bond on the substrate surface compared to their stable gas-phase counterparts.

The Result: Low-Temperature Deposition

Because the plasma provides the necessary activation energy, the substrate itself does not need to be heated intensely. The process can run effectively at temperatures below 200°C.

This low-temperature environment is what makes PECVD ideal for depositing films of materials like silicon nitride or amorphous silicon onto heat-sensitive substrates without causing thermal damage.

Understanding the Key Advantages and Trade-offs

Advantage: Reduced Thermal Stress

Even for substrates that can tolerate some heat, a large temperature difference between the hot deposition process and the cooler substrate creates thermal stress. This can cause the deposited film to crack or delaminate.

PECVD’s low operating temperature minimizes this thermal gradient, leading to more stable and adherent films.

Advantage: Control Over Film Properties

In PECVD, process parameters like plasma power and gas flow can be adjusted independently of temperature. This gives engineers precise control over the plasma density and energy.

This control allows for fine-tuning of the film’s final properties, such as its density, refractive index, and internal stress, which is more difficult in a purely thermal system.

Trade-off: Potential for Plasma Damage

While plasma is the key enabler, it is also a source of high-energy ion bombardment. If not properly controlled, this bombardment can cause microscopic damage to the substrate surface or the growing film, affecting its performance.

Trade-off: Film Purity

PECVD precursor gases (like silane, SiH₄) often contain hydrogen. Because of the lower process temperature, not all of this hydrogen is driven out of the film during deposition. This residual hydrogen can impact the film's electrical and optical properties, a factor that must be considered for certain applications.

Making the Right Choice for Your Project

Choosing a deposition method requires understanding your primary goal.

- If your primary focus is depositing on polymers, plastics, or other low-temperature materials: PECVD is the clear and often only viable choice.

- If your primary focus is achieving the highest possible film purity and density for a heat-tolerant substrate: Thermal CVD may offer benefits, as the high heat can produce denser films with fewer impurities like hydrogen.

- If your primary focus is tuning specific film properties like stress or microstructure: PECVD provides a wider process window and more independent control variables than thermal alternatives.

Ultimately, understanding that PECVD replaces heat energy with plasma energy is the key to leveraging it effectively for your specific material and application.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | Below 200°C, vs. 1,000°C for traditional CVD |

| Key Benefit | Prevents melting, degradation, or warping of heat-sensitive substrates |

| Mechanism | Uses plasma energy instead of thermal energy for chemical reactions |

| Advantages | Reduced thermal stress, better film adhesion, control over film properties |

| Trade-offs | Potential plasma damage, residual hydrogen affecting film purity |

| Ideal For | Polymers, plastics, and other low-temperature materials |

Unlock the potential of PECVD for your heat-sensitive substrates with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions, including our specialized CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're working with polymers, plastics, or other sensitive materials. Contact us today to discuss how our tailored PECVD solutions can enhance your deposition processes and drive innovation in your lab!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the role of temperature in PECVD? Optimize Film Quality and Substrate Protection

- What are gas barrier films, and how is PECVD involved in their creation? Discover Advanced Packaging Solutions

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What is the difference between PVD and PECVD? Choose the Right Thin-Film Coating Technology

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab