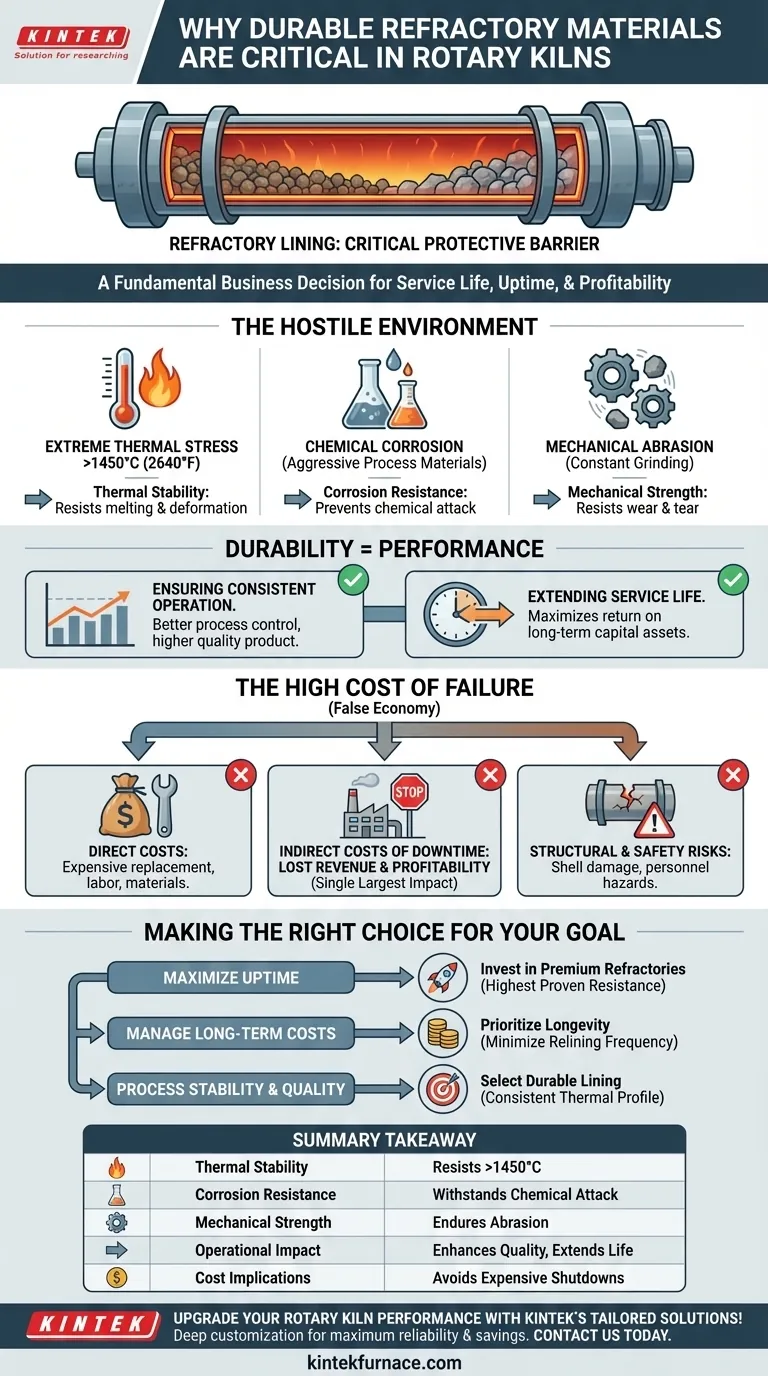

At their core, durable refractory materials are the critical protective lining that allows a rotary kiln to function. They are specifically engineered to withstand the kiln's punishing internal environment of extreme heat, chemical attack, and mechanical abrasion, ensuring the steel shell remains intact and the operation can continue without catastrophic failure.

The selection of refractory material is not merely a technical detail; it is a fundamental business decision that directly dictates the kiln's service life, operational uptime, and overall profitability.

The Hostile Environment Inside a Rotary Kiln

To understand the importance of durability, you must first appreciate the conditions the refractory lining must endure. It forms the barrier between the superheated process and the structural steel shell of the kiln.

Extreme Thermal Stress

Rotary kilns operate at incredibly high temperatures, often exceeding 1450°C (2640°F). The refractory must have high thermal stability to resist this heat without melting, deforming, or breaking down.

Chemical Corrosion

The raw materials and fuels used in processes like cement or lime production are often chemically aggressive. The refractory lining must have high corrosion resistance to prevent being eaten away by the alkaline or acidic compounds within the kiln.

Mechanical Abrasion

As the kiln rotates, the solid charge of material constantly tumbles and grinds against the lining. This creates significant physical stress, requiring the refractory to have high mechanical strength to resist wear and tear.

Why Durability Translates to Performance

A refractory's ability to withstand the kiln's environment over long periods is what defines its durability. This characteristic is the foundation for operational efficiency and reliability.

Ensuring Consistent Operation

A stable and intact refractory lining provides a consistent and predictable thermal environment inside the kiln. This allows for better process control and a higher quality final product.

Extending Service Life

Rotary kilns are designed as long-term capital assets. Durable, high-quality refractories are essential to achieving that extended service life, maximizing the return on a very significant investment.

Understanding the Trade-offs: The High Cost of Failure

Choosing a less-durable refractory to save on initial material costs is a false economy. The consequences of premature refractory failure are severe and far outweigh any upfront savings.

Direct Costs of Replacement

When a refractory lining fails, the kiln must be shut down. The process of cooling the kiln, tearing out the old lining, and installing a new one is an expensive, labor-intensive, and time-consuming task.

Indirect Costs of Downtime

For most industrial plants, the cost of lost production during a kiln shutdown is the single largest financial impact. Every hour the kiln is offline represents lost revenue and profitability.

Structural and Safety Risks

A catastrophic refractory failure can allow extreme heat to reach the kiln's steel shell. This can cause warping, permanent damage to the kiln itself, and create significant safety hazards for personnel.

Making the Right Choice for Your Goal

Selecting the correct refractory is about aligning the material's properties with your primary operational and financial objectives.

- If your primary focus is maximizing production uptime: Invest in premium refractories with the highest proven thermal, chemical, and mechanical resistance for your specific process.

- If your primary focus is managing long-term operational costs: Prioritize refractory longevity to minimize the frequency of costly relining projects and associated production losses.

- If your primary focus is process stability and product quality: Select a durable lining that maintains its integrity, ensuring a consistent thermal profile for reliable production outcomes.

Ultimately, choosing a durable refractory is an investment in the operational continuity and economic viability of your entire facility.

Summary Table:

| Key Aspect | Importance in Rotary Kilns |

|---|---|

| Thermal Stability | Resists temperatures over 1450°C, preventing melting and deformation. |

| Corrosion Resistance | Withstands chemical attacks from alkaline or acidic compounds. |

| Mechanical Strength | Endures abrasion from tumbling materials, reducing wear and tear. |

| Operational Impact | Enhances process control, product quality, and extends kiln service life. |

| Cost Implications | Avoids expensive shutdowns and replacements, improving profitability. |

Upgrade your rotary kiln performance with KINTEK's tailored solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique process needs, enhancing durability, uptime, and cost-efficiency. Contact us today to discuss how we can optimize your kiln's refractory lining for maximum reliability and savings!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control