At its core, a ceramic infrared heater's environmental advantage comes from two primary factors: its clean operation, which produces no on-site toxic emissions, and its material composition, which supports a more sustainable lifecycle from manufacturing to disposal. Unlike heaters that burn fuel, ceramic heaters do not release pollutants like carbon monoxide into your immediate environment.

The "environmentally friendly" label for ceramic infrared heaters is not just about avoiding smoke or fumes. It reflects a combination of zero operational emissions, the use of sustainable and recyclable materials, and a highly efficient method of delivering heat that can significantly reduce overall energy consumption.

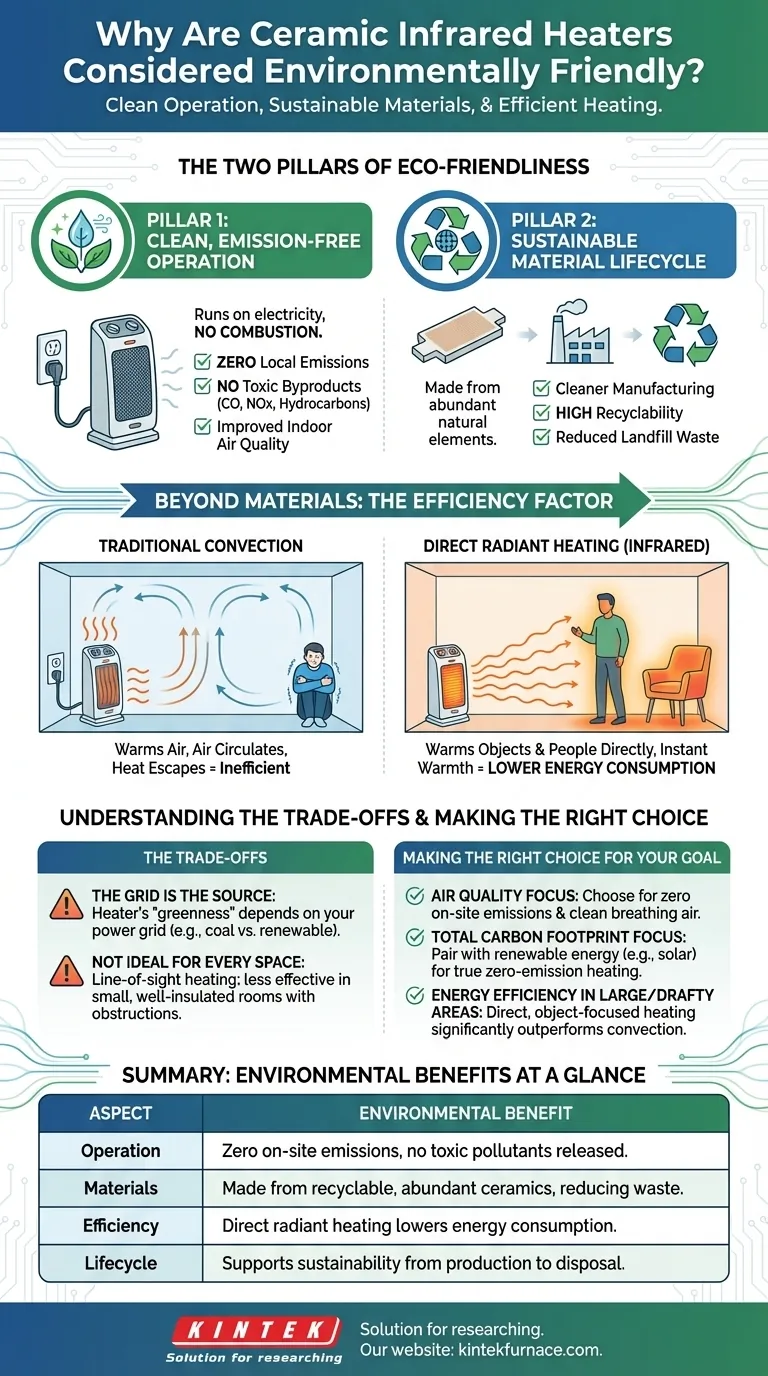

The Two Pillars of Eco-Friendliness

To properly assess the environmental claims, we must look at both how the heater operates and what it's made of. Both aspects contribute to its smaller environmental footprint compared to traditional alternatives.

Pillar 1: Clean, Emission-Free Operation

The most immediate environmental benefit is air quality. Ceramic infrared heaters run on electricity and do not involve any form of combustion.

This means they produce zero local emissions. There are no toxic byproducts like carbon monoxide, nitrogen oxides, or unburned hydrocarbons released into the space being heated. This stands in stark contrast to gas, propane, or kerosene heaters, which must be properly vented to be used safely indoors.

Pillar 2: Sustainable Material Lifecycle

The environmental impact of a product begins long before it's turned on. The materials and manufacturing processes for ceramic elements are a key part of their eco-friendly profile.

Ceramic is a stable, inert material made from abundant natural elements. The manufacturing process is often cleaner than that for complex metal alloys. Furthermore, these elements have high recyclability, reducing landfill waste and the need for virgin materials at the end of the product's life.

Beyond Materials: The Efficiency Factor

A heater's true environmental impact is also tied to its energy efficiency. Wasting energy places an unnecessary burden on the power grid, which may itself rely on fossil fuels. This is where the "infrared" aspect becomes critical.

Direct Radiant Heating vs. Convection

Traditional convection heaters work by warming the air, which then circulates to warm the people and objects in a room. This is inefficient in large or poorly insulated spaces, as heated air can easily escape.

Infrared heaters work like the sun. They emit infrared waves that travel through the air until they are absorbed by a solid object—a person, a piece of furniture, or the floor. This directly warms the objects in the room, not the air in between.

The Impact on Overall Energy Consumption

By heating objects and people directly, you feel warm faster and more effectively. This allows you to achieve the same level of comfort with a lower overall energy input, especially in targeted applications like a workshop, garage, or patio. This fundamental efficiency is a powerful, though indirect, environmental benefit.

Understanding the Trade-offs

No technology is a perfect solution. An objective analysis requires acknowledging the limitations and context of a heater's environmental impact.

The Grid is the True Source

A ceramic infrared heater is only as "green" as the electricity that powers it. If your electrical grid is heavily reliant on coal or natural gas, then your heater is indirectly responsible for emissions at the power plant. Its benefit remains zero local emissions, but its overall carbon footprint is tied to your energy provider.

Not Ideal for Every Space

Radiant heat is line-of-sight. It is excellent for spot-heating or in open areas but can create uneven heating in a small, well-insulated room where objects might block the heat from reaching other parts of the space. In such a scenario, a simple convection heater might provide more even comfort.

Making the Right Choice for Your Goal

Your specific goal will determine if a ceramic infrared heater is the most environmentally sound choice for you.

- If your primary focus is indoor air quality and safety: Ceramic infrared is an exceptional choice, as its zero on-site emissions keep your breathing air clean and safe.

- If your primary focus is minimizing your total carbon footprint: Pair a ceramic infrared heater with a renewable energy source, such as solar panels, to create a truly zero-emission heating system.

- If your primary focus is energy efficiency in a large or drafty area: The direct, object-focused heating of an infrared unit will significantly outperform a convection heater that wastes energy heating air that is quickly lost.

By understanding these principles, you can leverage ceramic infrared technology as a strategic tool for efficient and clean thermal management.

Summary Table:

| Aspect | Environmental Benefit |

|---|---|

| Operation | Zero on-site emissions, no toxic pollutants released |

| Materials | Made from recyclable, abundant ceramics, reducing waste |

| Efficiency | Direct radiant heating lowers energy consumption |

| Lifecycle | Supports sustainability from production to disposal |

Upgrade to Eco-Friendly Heating with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Experience reduced emissions and enhanced efficiency—contact us today to discuss how our solutions can benefit your lab!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Spark Plasma Sintering SPS Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs