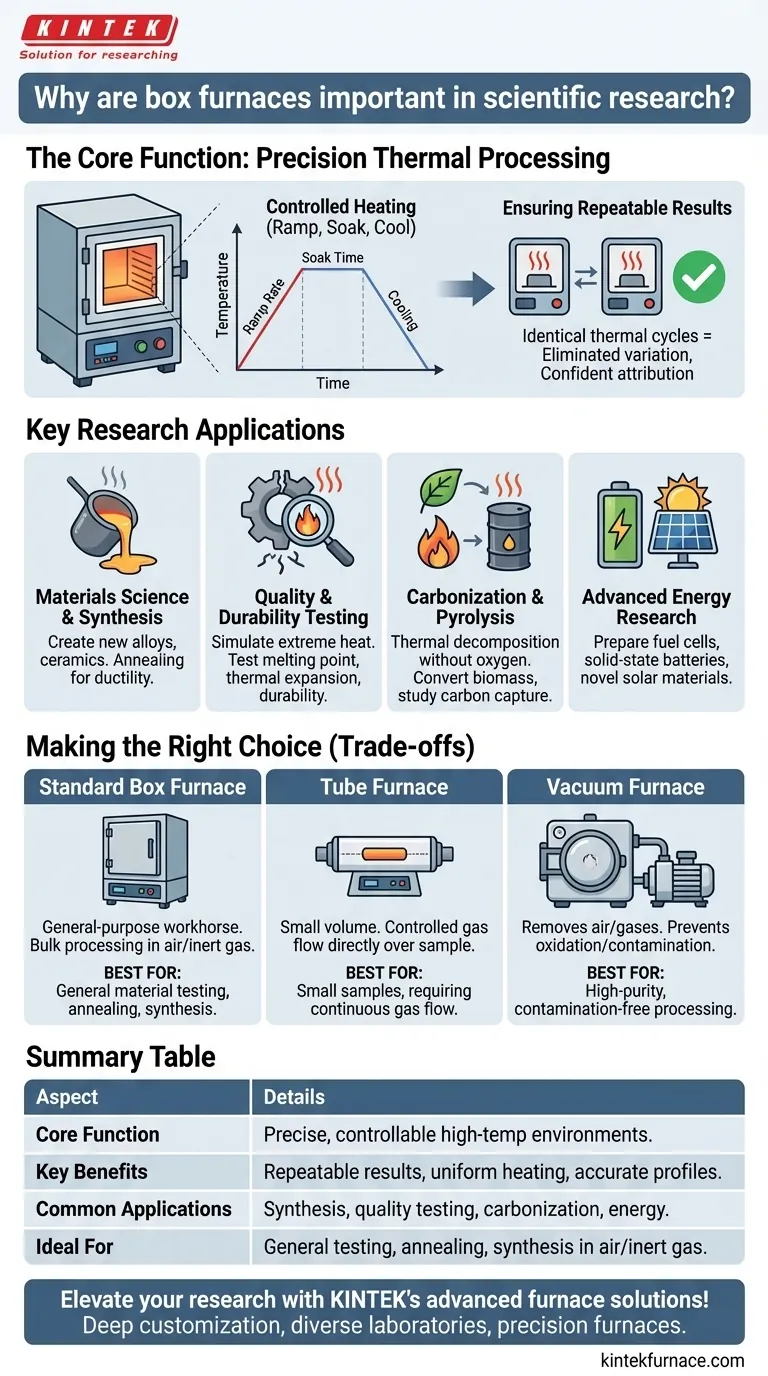

In short, box furnaces are critical to scientific research because they provide a highly precise and controllable high-temperature environment. This capability is the cornerstone for developing new materials, testing their properties under extreme conditions, and ensuring that experiments are repeatable and scientifically valid.

The true value of a box furnace in a research setting is not just its ability to get hot, but its power to execute a precise thermal profile—controlling heating rates, hold times, and cooling—with exceptional accuracy. This transforms heat from a blunt instrument into a precision tool for scientific discovery.

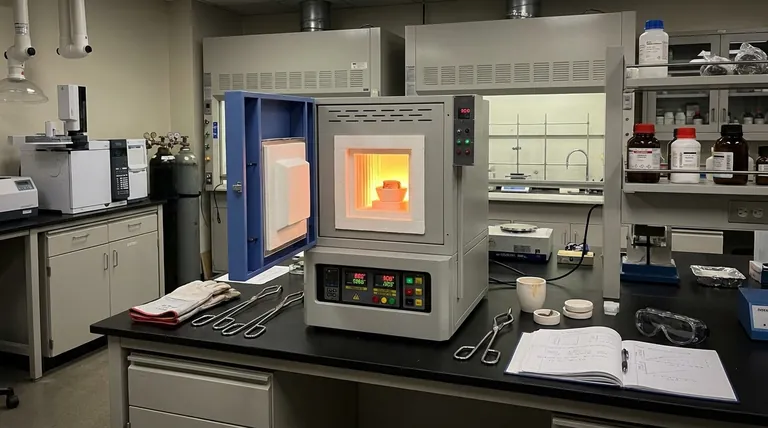

The Core Function: Precision Thermal Processing

At its heart, a box furnace is an insulated chamber designed to achieve uniform high temperatures. However, its importance in research stems from the control systems that govern its operation.

The Principle of Controlled Heating

Scientific experiments demand consistency. A box furnace allows researchers to program a precise "recipe" of heat treatment, defining how quickly the temperature rises (ramp rate), how long it stays at a specific temperature (soak or dwell time), and how it cools.

This level of control is non-negotiable for studying how thermal energy drives physical and chemical changes in a material.

Ensuring Repeatable Results

The scientific method relies on repeatability. A box furnace ensures that a sample tested today undergoes the exact same thermal cycle as a sample tested a month from now.

This consistency eliminates temperature variation as a variable, allowing scientists to confidently attribute observed changes in a material to the specific process being studied.

Key Research Applications

The ability to precisely control heat unlocks a vast range of experimental possibilities across multiple scientific domains.

Materials Science and Synthesis

This is the most common application. Researchers use box furnaces to create new alloys, ceramics, and composite materials by heating constituent elements to the point of fusion or reaction. They also use them for annealing, a process of heating and slow cooling to remove internal stresses and improve a material's ductility.

Quality and Durability Testing

Box furnaces are used to simulate the long-term effects of high-temperature environments on components. By subjecting a material to extreme heat, researchers can test its melting point, thermal expansion, and overall durability, which is crucial for engineering applications in aerospace, energy, and automotive industries.

Carbonization and Pyrolysis

In environmental and energy research, furnaces are essential for processes like pyrolysis—the thermal decomposition of organic matter in the absence of oxygen. This is used to convert biomass into biofuels and to study carbon capture technologies.

Advanced Energy Research

The development of next-generation energy solutions relies heavily on thermal processing. Box furnaces are used to prepare and test materials for fuel cells, solidify components for solid-state batteries, and synthesize novel materials for solar panels.

Understanding the Trade-offs and Alternatives

While versatile, the standard box furnace is one of several thermal processing tools. The specific experimental need dictates the right choice.

The Standard Box Furnace

This is the general-purpose workhorse. It is ideal for processing samples in an air atmosphere or with a simple inert gas purge. Its larger chamber is well-suited for bulk material processing or treating multiple samples at once.

The Tube Furnace

A tube furnace uses a narrow ceramic or quartz tube as its heating chamber. Its smaller volume and cylindrical shape make it ideal for processing small or powdered samples, especially when a controlled flow of gas must pass directly over the material.

The Vacuum Furnace

A vacuum furnace is a specialized system that removes air and other gases from the chamber before heating. This is essential for processes where atmospheric oxygen would cause unwanted oxidation or contamination. It is critical for high-purity metals, advanced electronics, and studying the intrinsic properties of a material without atmospheric interference.

Making the Right Choice for Your Research

Choosing the correct furnace is a foundational decision that impacts the validity and relevance of your experimental results.

- If your primary focus is general material testing, annealing, or synthesis in air: A standard box furnace offers the best combination of versatility and capacity.

- If your primary focus is processing small samples or requiring a continuous gas flow: A tube furnace provides a more controlled and efficient environment.

- If your primary focus is preventing any oxidation or atmospheric contamination: A vacuum furnace is the only tool that can guarantee the required high-purity conditions.

Ultimately, selecting the right thermal processing tool is about aligning the equipment's capabilities with the precise question you are trying to answer.

Summary Table:

| Aspect | Details |

|---|---|

| Core Function | Provides precise, controllable high-temperature environments for thermal processing. |

| Key Benefits | Ensures repeatable results, uniform heating, and accurate thermal profiles for experiments. |

| Common Applications | Materials synthesis, quality testing, carbonization, and advanced energy research. |

| Ideal For | General material testing, annealing, and synthesis in air or inert gas atmospheres. |

Elevate your research with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our tailored solutions can drive your scientific discoveries forward!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution