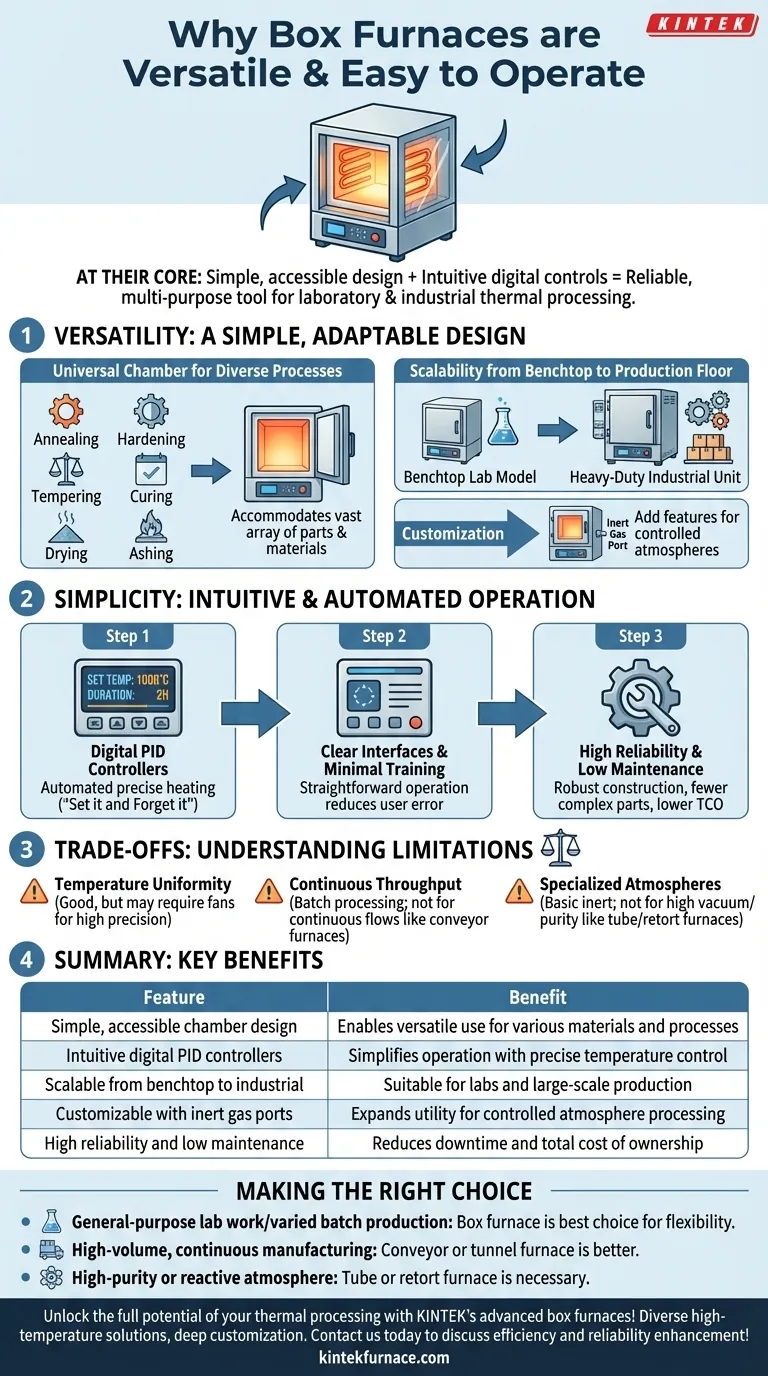

At their core, box furnaces are considered versatile and easy to operate because of their fundamental design: a simple, accessible chamber that can be built in various sizes and is managed by intuitive digital controls. This combination of a straightforward structure and modern automation makes them a reliable, multi-purpose tool for countless thermal processing applications in both laboratory and industrial settings.

The true value of a box furnace lies not in performing one specialized task perfectly, but in performing a wide range of essential tasks reliably and simply. They are the workhorses of thermal processing precisely because their design prioritizes adaptability and user-friendliness over niche specialization.

The Foundation of Versatility: A Simple, Adaptable Design

A box furnace’s versatility doesn't come from complex features, but from its elemental simplicity. The basic cubic or rectangular chamber is a blank canvas for thermal processing.

A Universal Chamber for Diverse Processes

The unobstructed, open design of the chamber allows it to accommodate a vast array of parts, materials, and sample sizes.

This makes it suitable for a wide range of applications, including annealing, hardening, tempering, curing, drying, and ashing.

Scalability from Benchtop to Production Floor

Box furnaces are not a one-size-fits-all solution; they are a single design principle applied across multiple scales.

They are available as compact tabletop models for research labs and as massive, heavy-duty industrial units for large-scale batch production, making the design relevant for nearly any operational size.

Customization for Broader Applications

The simple design is easily modified. Manufacturers can add features like inert gas ports to allow for processing in controlled atmospheres, significantly expanding the furnace's utility beyond heating in ambient air.

The Core of Simplicity: Intuitive and Automated Operation

Ease of use is a primary engineering goal for modern box furnaces. The focus is on achieving precise, repeatable results with minimal operator intervention or training.

The Role of Digital PID Controllers

Most modern box furnaces feature digital controllers (often PID, for Proportional-Integral-Derivative) that automate the heating process.

Users simply input the target temperature and duration, and the controller manages the power to the heating elements with high precision. This "set it and forget it" functionality drastically simplifies operation.

Clear Interfaces and Minimal Training

The operational interface, whether a simple control panel or a software GUI, is designed for clarity. Starting, stopping, and monitoring the process requires little specialized knowledge.

This straightforward operation reduces the potential for user error and minimizes the need for extensive training.

High Reliability and Low Maintenance

The simple, robust construction of box furnaces, often refined over decades of manufacturing, results in exceptional reliability and longevity.

With fewer complex mechanical parts to fail, they require minimal maintenance, ensuring more uptime and a lower total cost of ownership.

Understanding the Trade-offs

While highly versatile, the box furnace is a generalist. Its primary strengths can become limitations when a highly specialized process is required.

Temperature Uniformity

While good, the temperature uniformity in a standard box furnace may not match that of furnaces designed specifically for high-precision applications. Convection fans can be added to improve it, but it's an inherent trade-off of the simple box design.

Continuous Throughput

Box furnaces are designed for batch processing. For continuous manufacturing workflows where parts move constantly through a heat cycle, a conveyor or tunnel furnace is a far more efficient solution.

Specialized Atmospheres

While a box furnace can be adapted for a basic inert atmosphere, it cannot compete with a dedicated retort or tube furnace for processes requiring high vacuum, high purity, or reactive gases. These specialized furnaces provide a much better seal and atmospheric integrity.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its core strengths to your primary goal.

- If your primary focus is general-purpose lab work or varied batch production: The box furnace is almost certainly your best choice for its unparalleled flexibility and ease of use.

- If your primary focus is high-volume, continuous manufacturing: A conveyor or tunnel furnace is engineered specifically for this workflow and will be a better investment.

- If your primary focus is processing in a high-purity or reactive atmosphere: A purpose-built tube or retort furnace is necessary to achieve the required process control and safety.

Ultimately, the enduring popularity of the box furnace is a testament to a design that effectively solves the most common thermal processing needs with simplicity and reliability.

Summary Table:

| Feature | Benefit |

|---|---|

| Simple, accessible chamber design | Enables versatile use for various materials and processes |

| Intuitive digital PID controllers | Simplifies operation with precise temperature control |

| Scalable from benchtop to industrial | Suitable for labs and large-scale production |

| Customizable with inert gas ports | Expands utility for controlled atmosphere processing |

| High reliability and low maintenance | Reduces downtime and total cost of ownership |

Unlock the full potential of your thermal processing with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and reliability!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What is the function of laboratory high-temperature box furnaces in T6 aluminum treatment? Key to Material Strength