In short, vacuum casting furnaces are engineered to process a specialized range of high-performance and reactive metals. This includes materials that would be compromised by exposure to air, such as titanium and its alloys, nickel-based superalloys, zirconium, hafnium, and other high-purity metals used in demanding applications like aerospace and electronics.

The critical function of a vacuum casting furnace isn't just to heat metal, but to melt and pour it in a highly controlled, oxygen-free environment. This prevents oxidation and contamination, which is the key to preserving the unique chemical and mechanical properties of advanced alloys.

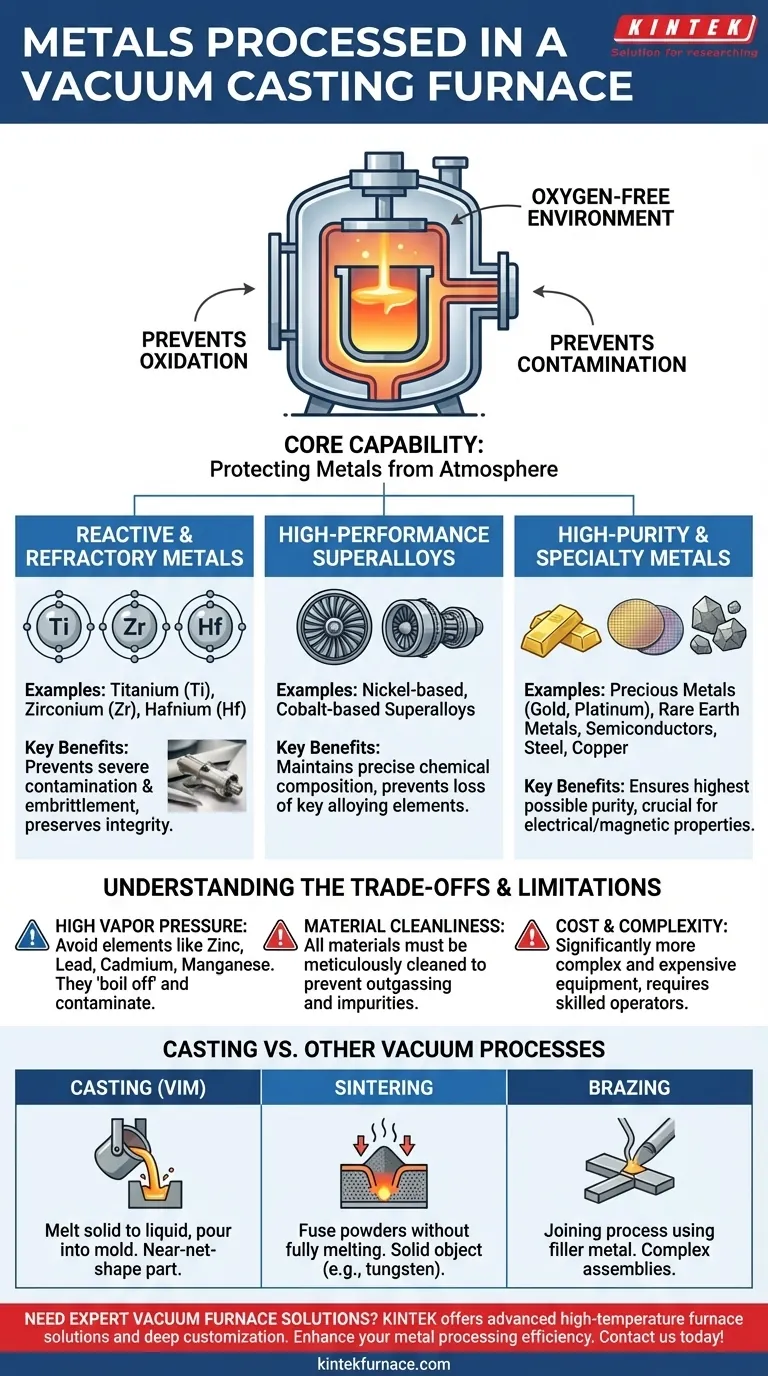

The Core Capability: Protecting Metals from Atmosphere

The primary advantage of vacuum casting is the elimination of atmospheric gases like oxygen and nitrogen. These gases can react with molten metal to form impurities (oxides and nitrides) that degrade its strength, ductility, and overall performance.

Reactive and Refractory Metals

Reactive metals like titanium (Ti), zirconium (Zr), and hafnium (Hf) have an extremely high affinity for oxygen, especially at elevated temperatures.

Melting these materials in air is impossible without causing severe contamination and embrittlement. A vacuum environment is the only way to melt and cast them while preserving their integrity.

High-Performance Superalloys

Nickel-based and cobalt-based superalloys are the backbone of the aerospace industry, used for turbine blades and other critical jet engine components.

Their performance relies on a precise and complex chemical composition. The vacuum prevents the loss of key alloying elements and ensures the final casting meets exacting metallurgical specifications.

High-Purity and Specialty Metals

This category includes precious metals (gold, platinum), rare earth metals, and metals for electronic components like semiconductors.

For these applications, even trace amounts of impurities can ruin the material's electrical or magnetic properties. Vacuum casting ensures the highest possible purity in the final product. Other common metals like steel alloys, stainless steel, and copper alloys can also be processed for high-purity applications.

Casting vs. Other Vacuum Furnace Processes

The term "vacuum furnace" describes a family of equipment, and casting is just one specific application. Understanding the distinctions is crucial for selecting the right technology.

Casting: Melting and Pouring

In vacuum casting, the primary goal is to melt a solid charge into a liquid state and pour it into a mold to create a near-net-shape part. This process is dominated by Vacuum Induction Melting (VIM) furnaces.

Sintering: Fusing Powders

Vacuum sintering does not fully melt the material. Instead, it heats compacted metal or ceramic powders to a temperature where the particles fuse together, forming a solid object. This is used for materials like tungsten, cemented carbides, and certain ceramics.

Brazing: Joining Components

Vacuum brazing is a joining process. It uses a filler metal with a lower melting point to bond two or more components together. The vacuum ensures a clean, strong, and flux-free joint, ideal for complex assemblies.

Understanding the Trade-offs and Limitations

While powerful, vacuum processing has specific constraints that dictate which materials are suitable and how they must be handled.

The Problem of High Vapor Pressure

Elements with high vapor pressure, such as zinc, lead, cadmium, and manganese, are generally avoided in high-vacuum processes.

Under vacuum, these elements can "boil off" from the molten alloy. This not only contaminates the furnace interior but also fundamentally changes the chemical composition and properties of your final casting.

The Mandate for Material Cleanliness

All materials, including the raw metal charge and the crucible, must be meticulously cleaned before being placed in the furnace.

Any surface contaminants like oils, greases, or residual oxides will outgas under vacuum. This releases impurities back into the controlled environment, defeating the purpose of the process and potentially ruining the melt.

Cost and System Complexity

Vacuum casting furnaces are significantly more complex and expensive to purchase, operate, and maintain than their air-melting counterparts. They require skilled operators and rigorous maintenance schedules to manage the vacuum pumps, seals, and control systems.

Making the Right Choice for Your Goal

Your choice of thermal processing technology depends entirely on your starting material and your desired final product.

- If your primary focus is casting reactive or high-purity metals (like titanium or superalloys): A vacuum induction melting (VIM) casting furnace is the industry standard for preventing contamination and achieving precise chemical control.

- If your primary focus is creating solid parts from metal or ceramic powders: You should investigate vacuum sintering, a different process that fuses particles without fully melting the material.

- If your primary focus is joining complex components with high-strength bonds: Vacuum brazing is the appropriate technique, using filler metals like nickel or gold in a controlled atmosphere.

Ultimately, understanding these distinctions ensures you select the precise technology required to achieve optimal material integrity and performance.

Summary Table:

| Metal Type | Examples | Key Benefits |

|---|---|---|

| Reactive Metals | Titanium, Zirconium, Hafnium | Prevents oxidation and contamination |

| Superalloys | Nickel-based, Cobalt-based | Maintains precise chemical composition |

| High-Purity Metals | Gold, Platinum, Semiconductors | Ensures electrical and magnetic purity |

| Other Alloys | Steel, Stainless Steel, Copper | Suitable for high-purity applications |

Need expert vacuum furnace solutions for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your metal processing efficiency and achieve superior results—Get in touch now!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity