In a dental laboratory, a porcelain furnace is the critical tool used to fabricate a range of highly precise ceramic and metal-ceramic restorations. These primarily include crowns, bridges, veneers, inlays, and onlays, which are essential for both restorative and cosmetic dentistry. The furnace executes controlled heating processes that transform raw dental porcelain into a strong, functional, and lifelike final product.

A porcelain furnace is not merely an oven; it is a precision instrument for transforming dental ceramics. Its core function is to execute controlled heating cycles for sintering, pressing, and glazing—processes that are fundamental to achieving the strength, fit, and lifelike aesthetics required of modern dental restorations.

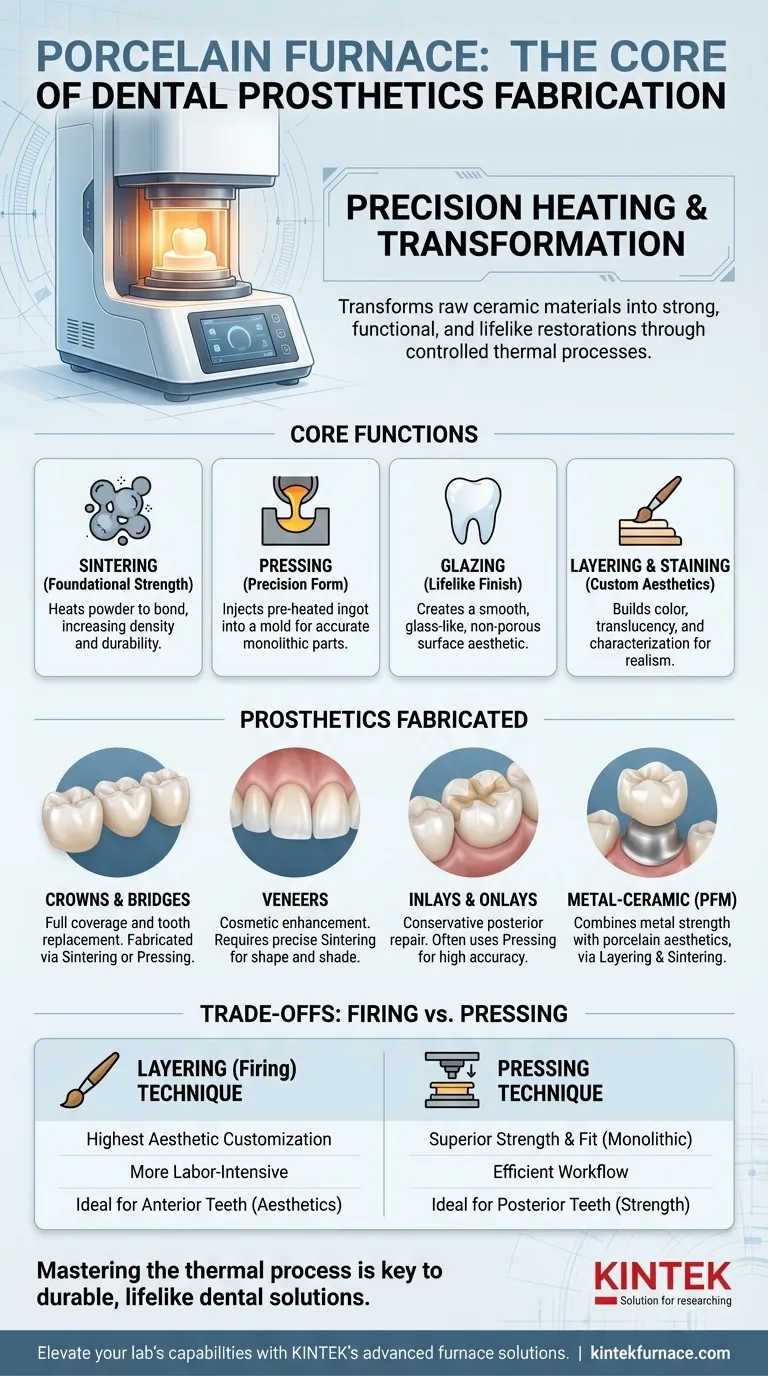

The Core Functions of a Porcelain Furnace

To understand what a porcelain furnace produces, you must first understand the key processes it performs. The furnace's ability to manipulate temperature with extreme precision is what enables the creation of high-quality prosthetics.

Sintering: Building Foundational Strength

Sintering is the process of heating porcelain powder to a specific temperature, just below its melting point. This causes the individual particles to bond and fuse together.

This densification process is what gives the ceramic its fundamental strength and hardness, shrinking the material into a solid, durable mass.

Pressing: Achieving Precision Form

Many modern furnaces also have a pressing function. In this technique, a pre-heated ceramic ingot is pressed in its molten state into a mold created using a lost-wax technique.

This method is used to fabricate monolithic (single-piece) restorations with exceptional accuracy and marginal fit, such as full-contour crowns and inlays.

Glazing: Creating a Lifelike Finish

Glazing is a final, lower-temperature firing cycle that creates a smooth, glass-like, non-porous surface on the restoration.

This "glaze" layer improves aesthetics, prevents staining, and creates a surface that is smooth against opposing teeth and easy for the patient to clean.

Layering and Staining: Customizing Aesthetics

For highly aesthetic restorations, technicians build up porcelain in multiple layers, with each layer representing a different aspect of the natural tooth (e.g., dentin and enamel). The furnace is used to fire each layer separately.

The furnace is also used for a final firing to set custom stains and characterizations on the surface, allowing the technician to perfectly match the restoration to the patient's adjacent teeth.

Prosthetics Fabricated with a Porcelain Furnace

The combination of sintering, pressing, and glazing allows dental technicians to create a wide variety of restorations.

Crowns and Bridges

A crown is a full-coverage restoration that caps an entire tooth. A bridge replaces one or more missing teeth by anchoring to adjacent teeth.

These can be made by layering porcelain over a metal or zirconia substructure (requiring multiple firings) or by pressing a full-contour ceramic material for maximum strength.

Veneers

Veneers are very thin shells of porcelain bonded to the front surface of teeth to improve their appearance.

Their fabrication requires incredibly precise firing cycles to achieve the desired shape, translucency, and shade without warping the delicate structure.

Inlays and Onlays

Inlays and onlays are more conservative restorations used to repair damage within the cusps (inlay) or over the cusps (onlay) of a posterior tooth.

These are frequently fabricated using the pressing technique to ensure a highly accurate fit within the prepared tooth structure.

Metal-Ceramic Restorations (PFM)

Porcelain-Fused-to-Metal (PFM) restorations have been a dental standard for decades.

The furnace is used to fire and fuse layers of opaque and body porcelain directly onto a precision-milled or cast metal framework, combining the strength of metal with the aesthetics of porcelain.

Understanding the Trade-offs: Firing vs. Pressing

The two dominant fabrication methods enabled by a porcelain furnace involve key trade-offs in aesthetics, strength, and workflow.

The Layering (Firing) Technique

This technique offers the highest potential for aesthetic customization. By building the restoration in layers, a skilled technician can perfectly mimic the depth, translucency, and subtle color variations of a natural tooth.

However, it is more labor-intensive, technique-sensitive, and can be less strong than a monolithic pressed ceramic, making it ideal for anterior teeth where aesthetics are paramount.

The Pressing Technique

Pressing creates a monolithic restoration that is extremely strong, dense, and durable. The fit is exceptionally precise due to the nature of the process.

While very aesthetic, achieving the highest level of nuanced characterization can be more challenging than with layering. It is often the preferred method for high-load posterior crowns and onlays where strength is the top priority.

Making the Right Choice for Your Goal

The decision to use a specific furnace function depends entirely on the clinical and aesthetic requirements of the final restoration.

- If your primary focus is maximum aesthetic customization: The traditional layering technique, with its multiple firing cycles, offers the greatest control over shade, translucency, and characterization.

- If your primary focus is strength and marginal fit for posterior teeth: The pressing technique is often superior, creating durable, monolithic restorations like full-contour crowns and onlays with high precision.

- If your primary focus is efficiency and a predictable workflow: Pressing ceramics often provides a more streamlined and reproducible process for common single-unit restorations.

Ultimately, mastering the porcelain furnace is about applying the right thermal process to transform ceramic materials into durable and lifelike dental solutions.

Summary Table:

| Prosthetic Type | Key Fabrication Process | Primary Use |

|---|---|---|

| Crowns and Bridges | Sintering, Pressing | Restore and replace teeth |

| Veneers | Sintering, Glazing | Cosmetic enhancement |

| Inlays and Onlays | Pressing | Conservative tooth repair |

| Metal-Ceramic (PFM) | Sintering, Layering | Combine strength and aesthetics |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs for precise sintering, pressing, and glazing processes. Contact us today to discuss how our tailored solutions can enhance the quality and efficiency of your prosthetic fabrication!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations