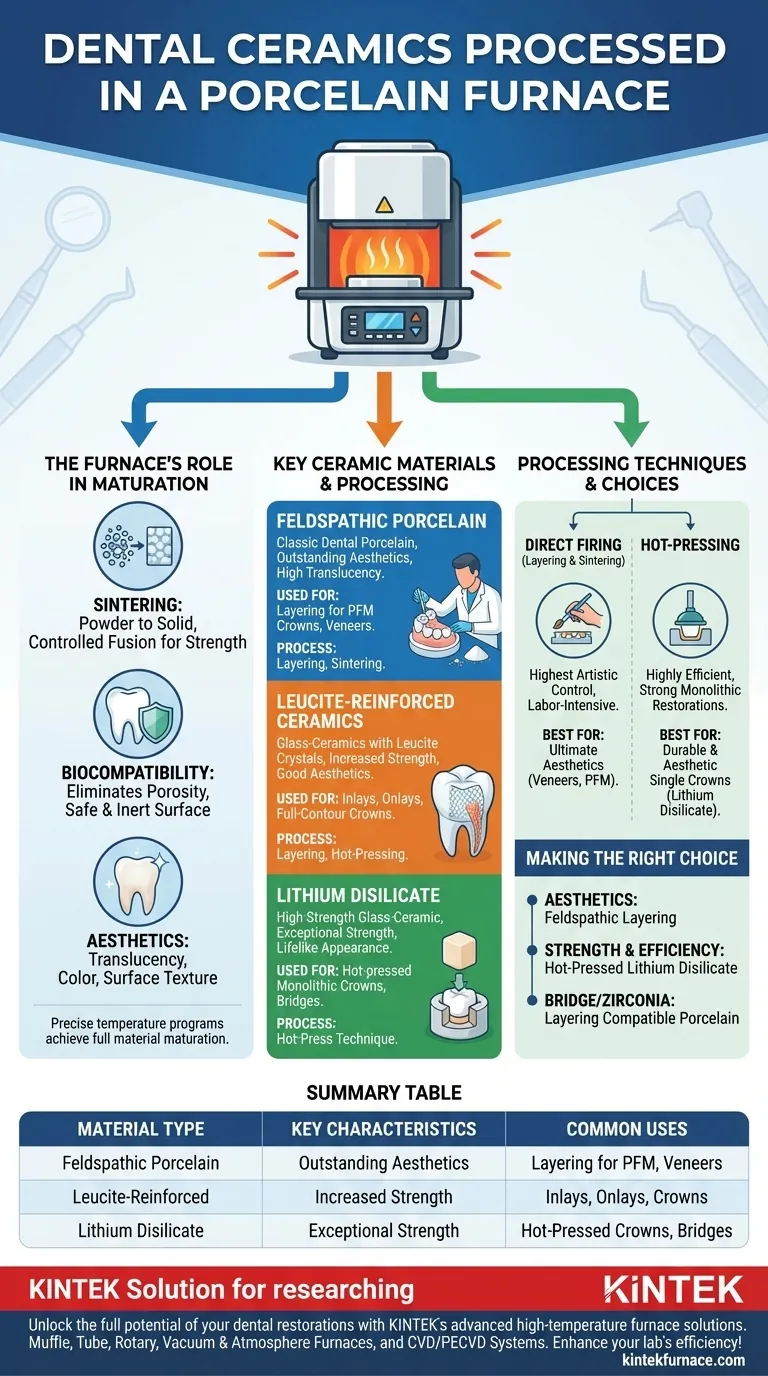

In short, a modern porcelain furnace is designed to process a range of dental ceramics, most notably feldspathic porcelains, leucite-reinforced ceramics, and lithium disilicate glass-ceramics. These materials are used to fabricate a wide variety of indirect restorations, including crowns, veneers, bridges, and inlays. The furnace's role is to apply precise heat cycles that transform the raw ceramic material into a strong, durable, and aesthetically pleasing final product.

The core function of a porcelain furnace is not simply to heat material, but to precisely control the transformation of ceramic from a raw state to a mature, biocompatible restoration. Understanding which materials are compatible is only the first step; the true challenge lies in mastering the firing process to achieve the desired clinical and aesthetic outcomes.

The Furnace's Role in Ceramic Maturation

A porcelain furnace is the central instrument for creating high-quality, indirect ceramic dental restorations. Its purpose extends far beyond simple heating; it executes highly specific temperature programs to achieve full material maturation.

Sintering: From Powder to Solid

The primary process is sintering. This involves heating powdered ceramic particles to a temperature where they fuse together, densify, and form a solid, coherent mass without fully melting.

This controlled fusion is what gives the final restoration its strength and stability. Without a precise firing cycle, the ceramic would be weak, porous, and clinically useless.

Ensuring Biocompatibility

The firing process is critical for ensuring the final restoration is biocompatible and safe for long-term use in the oral environment.

Proper sintering eliminates porosity and creates a stable, inert surface that resists plaque accumulation and will not leach materials into the patient's system.

Mastering Final Aesthetics

A technician's artistry is realized through the furnace. The final appearance of a restoration—its translucency, color (hue and chroma), and surface texture—is locked in during the final firing and glazing cycles.

Slight variations in temperature or hold times can dramatically alter a restoration's appearance, making the furnace's precision paramount for achieving a natural look.

Key Ceramic Materials and Their Processing

Different ceramics require different firing parameters, but several key types are routinely processed in dental laboratory furnaces.

Feldspathic Porcelain

This is the classic dental porcelain, known for its outstanding aesthetics and translucency. It is most often used as a layering ceramic.

Technicians apply it in powder/liquid form over a metal (PFM) or high-strength ceramic (e.g., zirconia) core. The furnace then sinters these layers to create the final tooth form and color.

Leucite-Reinforced Ceramics

These are glass-ceramics that contain leucite crystals, which increase the material's strength and resistance to fracture compared to traditional feldspathic porcelain.

They are strong enough for single-unit restorations like inlays, onlays, and full-contour crowns, offering a good balance of durability and aesthetics. They are processed through both layering and hot-pressing techniques.

Lithium Disilicate

This high-strength glass-ceramic is one of the most popular materials in modern dentistry due to its exceptional strength and lifelike appearance.

It is most commonly processed via the hot-press technique. A pre-made ingot of lithium disilicate is heated to a plastic state in a specialized press furnace and then forced into a mold to create a monolithic restoration. The furnace is then used again for stain and glaze cycles to achieve the final custom shade.

Understanding the Trade-offs: Firing vs. Pressing

While often performed in similar-looking equipment, the methods of firing and pressing serve different purposes and are suited for different materials and clinical goals.

Direct Firing (Layering and Sintering)

This technique involves building the restoration by hand, layer by layer, using porcelain powders. It offers the highest level of artistic control for custom shading and characterization.

This method is essential for porcelain-fused-to-metal (PFM) crowns and for veneering zirconia frameworks. It is more labor-intensive but allows for unparalleled aesthetic results.

Hot-Pressing

This method involves creating a wax pattern of the final restoration, investing it, and then pressing a ceramic ingot into the resulting mold under heat and pressure.

It is highly efficient and produces very strong, dense, and accurately fitting monolithic restorations. It is the dominant method for fabricating single-unit lithium disilicate crowns.

The Cost and Workflow Equation

Direct-fired systems can have a lower initial equipment cost. However, the manual layering process is skill-dependent and time-consuming.

Hot-press systems streamline the production of monolithic crowns, leading to higher efficiency and predictability, though the initial equipment investment may be greater.

Making the Right Choice for Your Goal

The material and process you choose depend entirely on the clinical requirements of the restoration.

- If your primary focus is ultimate aesthetics for veneers: Feldspathic porcelain, applied via traditional layering, remains a gold standard.

- If your primary focus is a durable and aesthetic single crown: Hot-pressed lithium disilicate offers an excellent combination of strength, efficiency, and beauty.

- If your primary focus is creating a bridge or veneering a zirconia substructure: Layering a compatible porcelain (feldspathic or otherwise) onto the high-strength core is the required technique.

Ultimately, the porcelain furnace is the tool that empowers technicians to unlock the full potential of these advanced dental materials.

Summary Table:

| Material Type | Key Characteristics | Common Uses |

|---|---|---|

| Feldspathic Porcelain | Outstanding aesthetics, high translucency | Layering for PFM crowns, veneers |

| Leucite-Reinforced Ceramics | Increased strength, good aesthetics | Inlays, onlays, full-contour crowns |

| Lithium Disilicate | Exceptional strength, lifelike appearance | Hot-pressed monolithic crowns, bridges |

Unlock the full potential of your dental restorations with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise porcelain furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for sintering, hot-pressing, and more. Contact us today to enhance your lab's efficiency and achieve superior clinical outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations