In short, a modern dental sintering furnace is a highly versatile tool capable of processing the three primary categories of high-performance dental ceramics: zirconia, glass-ceramics like lithium disilicate, and traditional feldspathic porcelains. Its core function is to execute precise, programmable heating and cooling cycles tailored to the unique requirements of each material.

The true value of a dental furnace isn't just its ability to reach high temperatures, but its precision in controlling the entire thermal cycle. This programmability is what allows a single machine to produce everything from incredibly strong zirconia bridges to highly aesthetic lithium disilicate veneers.

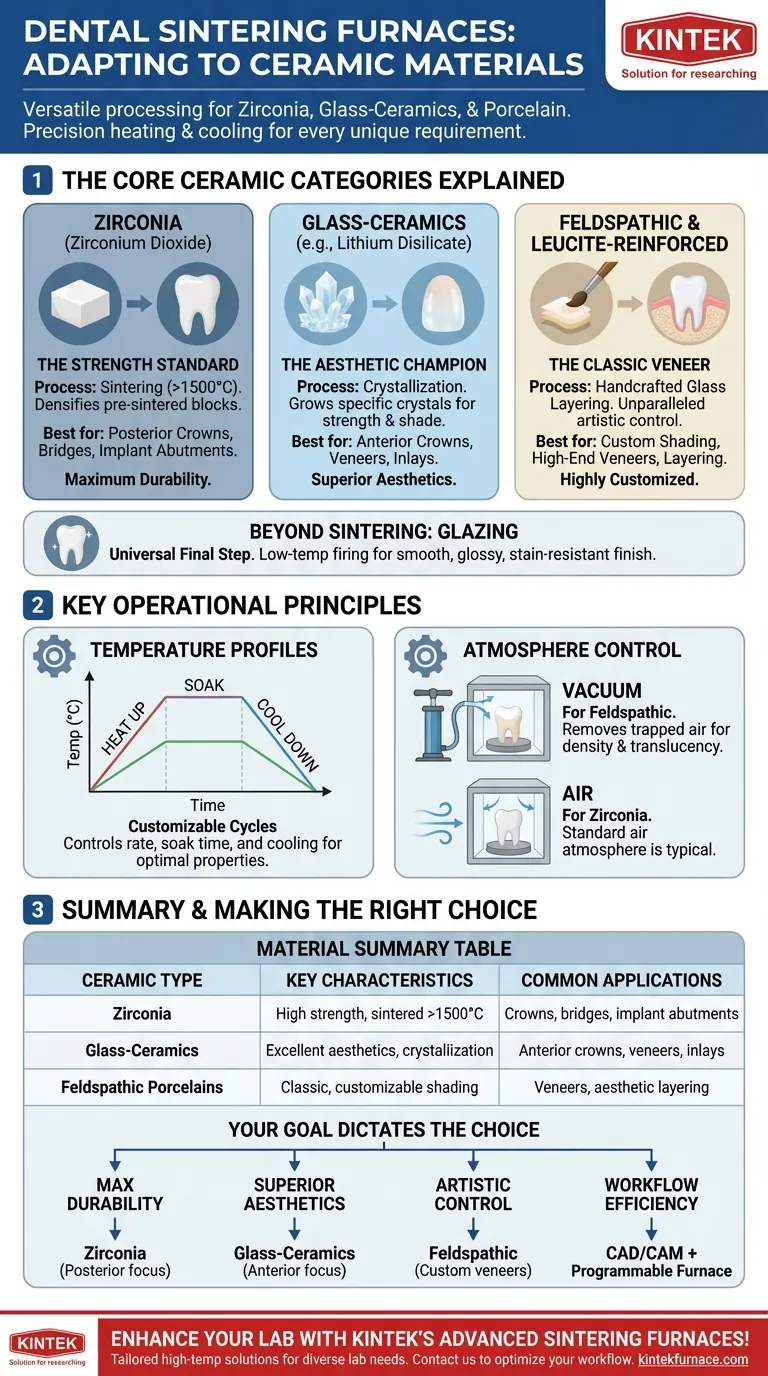

The Core Ceramic Categories Explained

Understanding the capabilities of a sintering furnace begins with understanding the materials it is designed to fire. Each category offers a different balance of strength, aesthetics, and clinical application.

Zirconia (Zirconium Dioxide): The Strength Standard

Zirconia is the benchmark for strength and durability in dental restorations. It is supplied to labs in a pre-sintered, chalk-like block that is milled using CAD/CAM technology.

The furnace then performs the critical sintering process, heating the zirconia to extremely high temperatures (often over 1500°C). This densifies the material, shrinking it to its final, incredibly hard state.

Its immense strength makes it the ideal choice for posterior crowns, multi-unit bridges, and implant abutments that must withstand significant chewing forces.

Glass-Ceramics (Lithium Disilicate): The Aesthetic Champion

This category, most famously represented by lithium disilicate, is prized for its exceptional aesthetics and lifelike translucency. It strikes an excellent balance between beauty and sufficient strength for many applications.

Unlike the simple sintering of zirconia, glass-ceramics undergo a process called crystallization. The furnace's precise heat control grows specific crystals within the glass matrix, transforming the material's properties to achieve final strength and shade.

These materials are the gold standard for anterior (front tooth) crowns, inlays, onlays, and veneers where appearance is the primary concern.

Feldspathic & Leucite-Reinforced Ceramics: The Classic Veneer

Feldspathic porcelains are the original, classic materials used in cosmetic dentistry. They are essentially a form of handcrafted glass, applied as a powder-liquid slurry and fired in the furnace.

These materials offer unparalleled control for custom shading and characterization, often used for high-end veneers or for layering over stronger zirconia or metal substructures to improve aesthetics. Leucite-reinforced versions add strength to this classic formula.

Beyond Sintering: Glazing

Nearly all ceramic restorations require a final glazing cycle. The same furnace is used for this lower-temperature firing, which melts a thin layer of glass onto the restoration's surface. This creates a smooth, stain-resistant, and high-gloss finish that mimics natural tooth enamel.

Understanding Key Operational Principles

The furnace's adaptability comes from its precise control over two key variables: the temperature profile and the atmospheric conditions.

The Critical Role of Temperature Profiles

Each ceramic material has a unique and non-negotiable temperature profile. This is not just about the peak temperature but the entire cycle: the rate of heating, how long it is held at specific temperatures (the "soak"), and the rate of cooling.

A furnace's ability to be programmed with dozens of custom profiles is what makes it so versatile. Using the wrong profile can result in a weak, discolored, or poorly fitting restoration.

Atmosphere Control: Vacuum vs. Air

Many high-end furnaces offer vacuum functionality. Firing certain porcelains, especially feldspathic types, under a vacuum pulls out trapped air, preventing bubbles and resulting in a denser, more translucent, and stronger material.

Other materials, like zirconia, are typically sintered in a normal air atmosphere. The ability to control the atmosphere is another layer of process control that ensures optimal results for a given material.

Making the Right Choice for Your Goal

Your clinical or business objective dictates the material choice, which in turn dictates the furnace program you will use.

- If your primary focus is maximum durability for posterior restorations: Zirconia is the material of choice due to its superior fracture resistance.

- If your primary focus is superior aesthetics for anterior restorations: Lithium disilicate and other glass-ceramics provide the best combination of lifelike translucency and strength.

- If your primary focus is highly customized veneers or aesthetic layering: Feldspathic porcelains offer the highest level of artistic control for expert technicians.

- If your primary focus is workflow efficiency: CAD/CAM-milled blocks of zirconia or lithium disilicate combined with a programmable furnace offer the most streamlined process.

Ultimately, the dental sintering furnace is the essential final step that transforms digitally designed or manually crafted shapes into biocompatible, functional, and aesthetic dental restorations.

Summary Table:

| Ceramic Type | Key Characteristics | Common Applications |

|---|---|---|

| Zirconia | High strength, sintered at >1500°C | Crowns, bridges, implant abutments |

| Glass-Ceramics (e.g., Lithium Disilicate) | Excellent aesthetics, crystallization process | Anterior crowns, veneers, inlays |

| Feldspathic Porcelains | Classic, customizable shading | Veneers, aesthetic layering |

Enhance your dental lab's capabilities with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior ceramic processing. Contact us today to discuss how our furnaces can optimize your workflow and deliver high-quality dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations