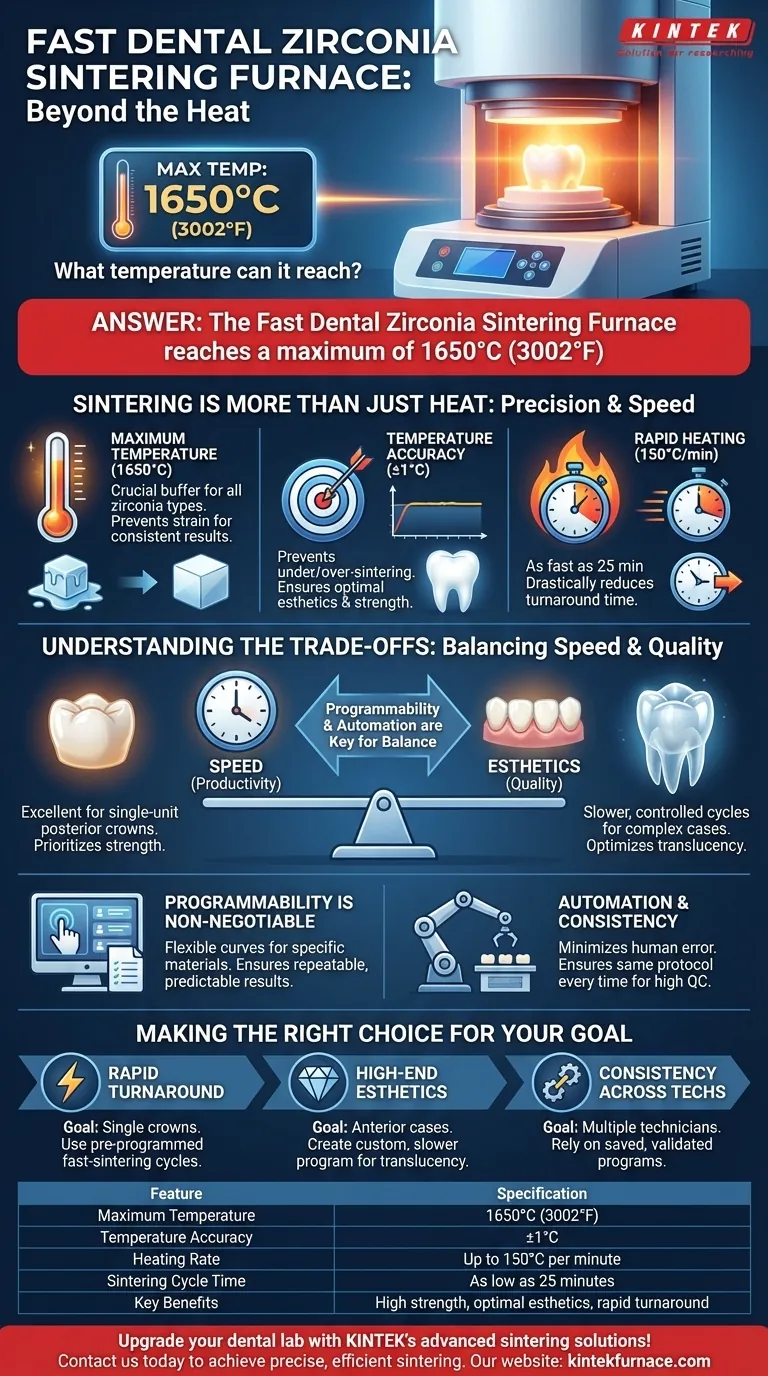

To answer your question directly, the Fast Dental Zirconia Sintering Furnace can reach a maximum temperature of 1650°C (3002°F). This high temperature capability ensures it can handle the sintering requirements for a wide range of zirconia materials used in modern dental restorations.

While maximum temperature is a critical specification, the true value of a modern sintering furnace lies in its ability to precisely control the entire temperature curve—balancing speed, accuracy, and flexibility to achieve optimal esthetics and strength.

Why Sintering Is More Than Just Heat

Sintering is the process that transforms a porous, chalk-like zirconia block into a dense, strong, and translucent final restoration. Simply reaching a high temperature is not enough; how you get there and how precisely you control the process is what determines the final quality.

The Role of Maximum Temperature

The 1650°C peak temperature provides a crucial buffer. Most zirconia materials sinter between 1450°C and 1550°C, so having a higher maximum ensures the furnace can comfortably and consistently reach the target without being strained.

The Key to Quality: Temperature Accuracy

A furnace's ability to maintain a set temperature without fluctuation is paramount. This model features a temperature accuracy of ±1°C. This precision prevents under-sintering (leading to weak restorations) or over-sintering (which can affect shade and translucency).

The Demand for Speed: Rapid Heating

Modern dental labs operate under tight deadlines. This furnace meets that demand with a heating rate of up to 150°C per minute, allowing it to complete a full sintering cycle in as little as 25 minutes for certain materials. This drastically reduces turnaround times compared to traditional 8-hour cycles.

Understanding the Trade-offs

Achieving speed and maintaining quality requires a sophisticated system. It's important to understand the balance between different operational modes and their impact on the final product.

Speed vs. Esthetics

Faster sintering cycles are excellent for productivity, especially for single-unit posterior crowns where strength is the priority. However, for highly esthetic anterior cases or complex multi-unit bridges, a slower, more controlled heating and cooling cycle may be necessary to achieve the best possible translucency and prevent thermal shock or warping.

Programmability is Non-Negotiable

Different zirconia materials (e.g., high-strength, high-translucency) have unique sintering protocols specified by the manufacturer. A furnace with flexible, programmable temperature curves is essential. This allows you to create and save specific programs for each material, ensuring repeatable and predictable results every time.

Automation and Consistency

Features like automated tray handling and touch screen controls minimize the chance of human error. By automating the process, the furnace ensures that every restoration follows the exact same protocol, leading to a higher standard of quality control and consistency across all cases.

Making the Right Choice for Your Goal

The furnace's capabilities allow you to tailor the process to the specific demands of each case.

- If your primary focus is rapid turnaround for single crowns: Utilize the pre-programmed fast-sintering cycles to maximize daily output without compromising strength.

- If your primary focus is high-end esthetics for anterior cases: Create a custom program with a slower heating rate and a longer holding time at the peak temperature to optimize translucency.

- If your primary focus is consistency across multiple technicians: Rely on saved, validated programs for specific zirconia brands to ensure every restoration meets the same quality standard.

Ultimately, a furnace with a high maximum temperature, precise control, and flexible programming empowers you to deliver exceptional results efficiently.

Summary Table:

| Feature | Specification |

|---|---|

| Maximum Temperature | 1650°C (3002°F) |

| Temperature Accuracy | ±1°C |

| Heating Rate | Up to 150°C per minute |

| Sintering Cycle Time | As low as 25 minutes |

| Key Benefits | High strength, optimal esthetics, rapid turnaround |

Upgrade your dental lab with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace expertise. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique needs. Contact us today to achieve precise, efficient sintering for superior dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab