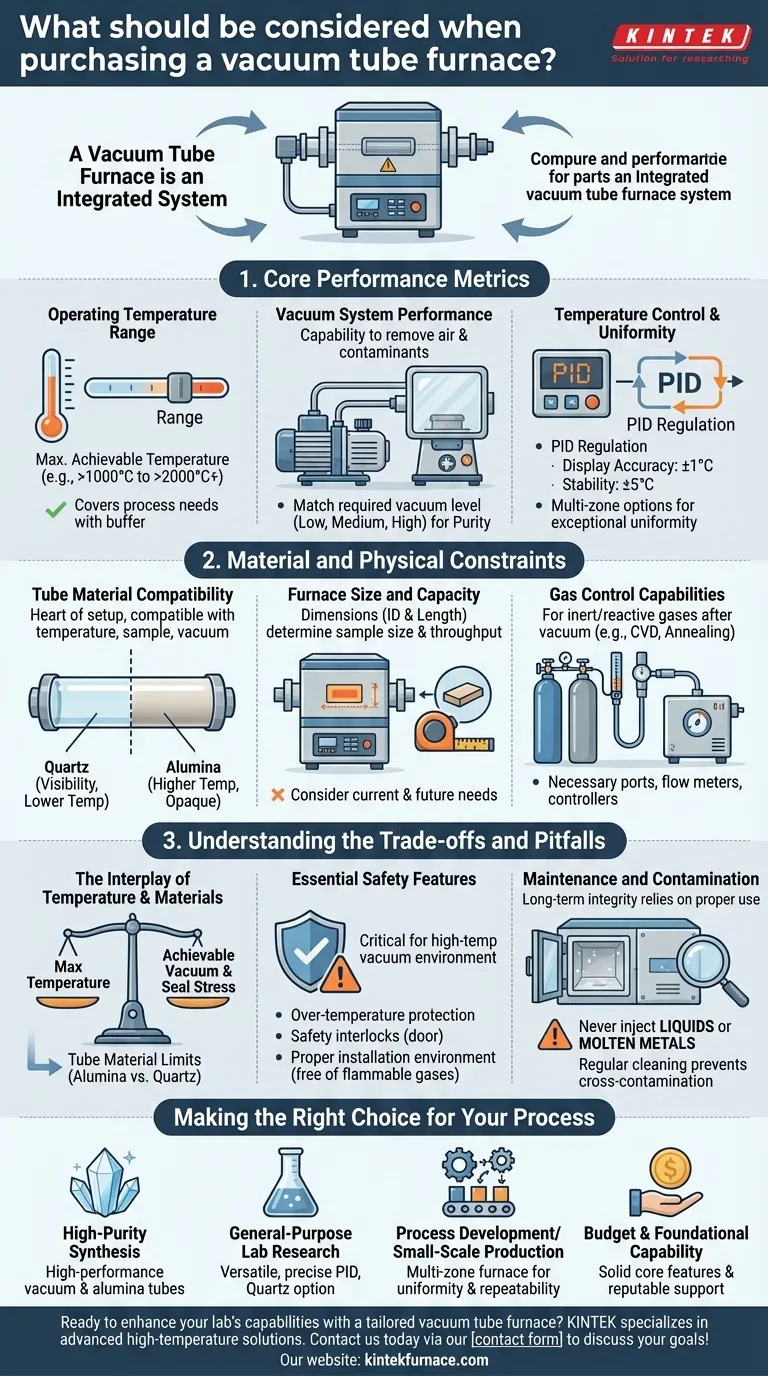

When purchasing a vacuum tube furnace, your decision must go beyond a simple temperature rating. You need to evaluate the entire system, including the furnace's temperature range, the material of the process tube, the performance of the vacuum system, the precision of the temperature controller, and the available gas control capabilities. Matching each of these components to your specific application is critical for achieving reliable and repeatable results.

A vacuum tube furnace is not a single product, but an integrated system. The central challenge is ensuring every component—from the heating element to the vacuum pump—works in concert to meet the precise atmospheric and thermal demands of your scientific process.

Core Performance Metrics

The primary function of the furnace is to create a specific thermal environment. These metrics define its ability to perform that core task.

Operating Temperature Range

The maximum achievable temperature is a primary filter for your selection. Many applications require temperatures exceeding 1000°C, and specialized models can reach above 2000°C.

Ensure the furnace's specified range comfortably covers your process requirements, providing a buffer for potential future needs.

Vacuum System Performance

The ability to create a controlled atmosphere is a key benefit. This starts with the vacuum system's capability to remove ambient air and contaminants.

You must match the vacuum pump system to your required vacuum level, whether it's a low, medium, or high vacuum. This directly impacts the purity of the environment inside the tube.

Temperature Control and Uniformity

Precise temperature management is non-negotiable for consistent outcomes. Modern furnaces use advanced control systems like PID regulation to minimize temperature fluctuations.

Look for specifications detailing temperature display accuracy (typically ±1°C) and temperature field stability (often ±5°C) along the heated zone. For processes requiring exceptional uniformity, consider a multi-zone furnace, which allows for independent temperature control across different sections of the tube.

Material and Physical Constraints

The physical components of the furnace dictate its compatibility with your materials and workflow.

Tube Material Compatibility

The process tube is the heart of your setup, and its material must be compatible with your maximum temperature, your sample materials, and your required vacuum level.

Common materials like quartz offer good visibility but have lower temperature limits than ceramics like alumina. The choice of tube material directly impacts the ultimate performance and safety of your operations.

Furnace Size and Capacity

The internal diameter and length of the furnace tube determine your maximum sample size and overall throughput.

Consider not only your current sample dimensions but also any potential need for processing larger or more numerous samples in the future.

Gas Control Capabilities

Many processes require the introduction of specific inert or reactive gases after a vacuum has been established.

If your work involves annealing, CVD, or other atmosphere-dependent processes, ensure the furnace is equipped with the necessary ports, flow meters, and controllers to manage your process gases accurately.

Understanding the Trade-offs and Pitfalls

A successful purchase requires understanding the system's limitations and operational requirements. Avoiding common mistakes is as important as choosing the right features.

The Interplay of Temperature and Materials

You cannot maximize every variable simultaneously. Pushing a furnace to its maximum temperature may place stress on seals and limit the achievable vacuum level.

Likewise, the process tube material creates a hard limit. An alumina tube can withstand higher temperatures than a quartz tube, but it is opaque and more susceptible to thermal shock if heated or cooled too rapidly.

Essential Safety Features

A high-temperature vacuum environment has inherent risks. Your furnace must be equipped with critical safety features like over-temperature protection and safety interlocks that shut down power if a door is opened.

Proper installation is also a safety function. The furnace must be placed in a working environment free of flammable, explosive, or corrosive gases.

Maintenance and Contamination

The long-term integrity of your furnace depends on proper use. Never inject liquids or molten metals directly into the hot furnace chamber, as this can cause catastrophic failure.

Regularly inspect and keep the furnace chamber clean to prevent cross-contamination between processes and ensure consistent performance.

Making the Right Choice for Your Process

Your final decision should be guided by a clear understanding of your primary research or production goal.

- If your primary focus is high-purity material synthesis: Prioritize a system with a high-performance vacuum pump and compatibility with high-purity alumina tubes to minimize contamination.

- If your primary focus is general-purpose lab research: Select a versatile furnace with precise PID control and consider a quartz tube option for processes where visual observation is beneficial.

- If your primary focus is process development or small-scale production: Invest in a multi-zone furnace to ensure exceptional temperature uniformity and repeatable results at scale.

- If your primary focus is budget and foundational capability: Ensure the core features—temperature range, basic vacuum, and safety interlocks—are solid and come from a reputable supplier who offers support.

Choosing the right vacuum tube furnace is an investment in the precision and control of your most critical processes.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Operating Temperature Range | Covers process needs with buffer (e.g., 1000°C to 2000°C+) |

| Vacuum System Performance | Matches required vacuum level (low, medium, high) for purity |

| Temperature Control and Uniformity | PID regulation, accuracy (±1°C), stability (±5°C), multi-zone options |

| Tube Material Compatibility | Quartz for visibility, alumina for high temp; affects safety and performance |

| Furnace Size and Capacity | Internal diameter and length for sample size and throughput |

| Gas Control Capabilities | Ports, flow meters for inert/reactive gases in processes like CVD |

| Safety Features | Over-temperature protection, safety interlocks, proper installation |

| Maintenance and Contamination | Avoid liquids/metal injection, regular cleaning for consistency |

Ready to enhance your lab's capabilities with a tailored vacuum tube furnace? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise temperature control, reliable vacuum performance, and optimal safety. Contact us today via our contact form to discuss how we can support your research or production goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents