At its core, operating a lab tube furnace safely requires a disciplined approach combining personal protective equipment (PPE), environmental awareness, and strict adherence to procedural steps. The most critical measures involve wearing heat-resistant gloves and safety glasses, ensuring proper ventilation to handle off-gassing, and following precise cooldown protocols to prevent thermal shock and exposure.

A tube furnace's safety is not guaranteed by a single action, but by a systematic process. True safety lies in understanding that the operator, the environment, and the equipment are interconnected parts of a system that must be managed from pre-operation checks through post-operation cleaning.

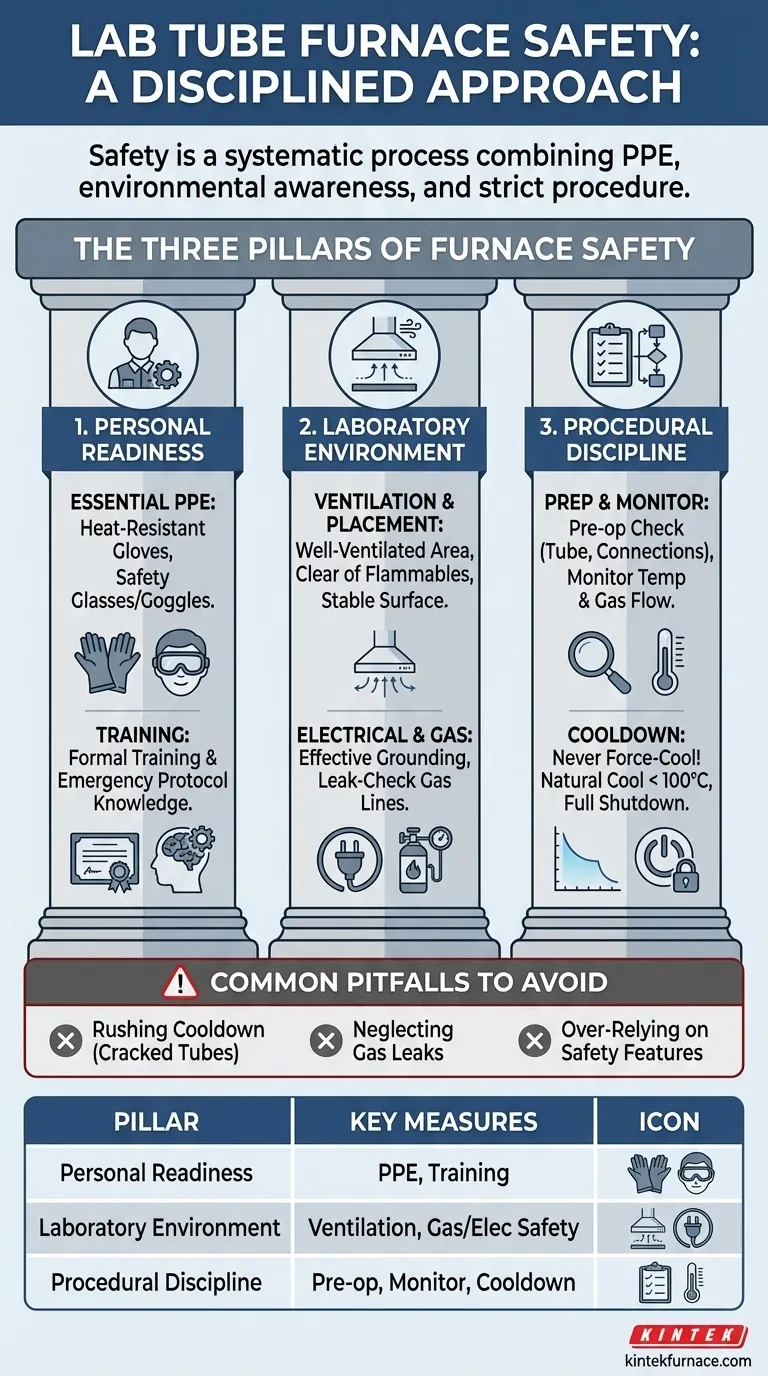

The Three Pillars of Furnace Safety

Safe operation is built on three foundational pillars. Neglecting any one of them introduces significant risk of personal injury, equipment damage, or experimental failure.

Pillar 1: Personal and Operator Readiness

The first line of defense is always the person operating the equipment.

Essential Personal Protective Equipment (PPE)

Always wear heat-resistant gloves when handling materials near the furnace, even after it has started cooling. High-temperature insulation can retain dangerous levels of heat for a long time.

Safety glasses or goggles are non-negotiable to protect against projectiles from unexpected pressure events or thermal shattering.

The Importance of Training

No one should operate a tube furnace without formal training. This must include a complete understanding of the operating procedure, shutdown sequences, and, most critically, the emergency shutdown protocol.

Pillar 2: The Laboratory Environment

The furnace's immediate surroundings are a critical safety factor.

Ventilation and Placement

The furnace must be located in a well-ventilated area, ideally under a fume hood, to safely exhaust any toxic gases or fumes released from the sample during heating.

Keep the area completely free of flammable and explosive materials. The high temperatures and powerful electrical components present a significant ignition risk.

Ensure the furnace is placed on a stable surface, away from sources of severe vibration, and in an area that is not prone to getting wet.

Electrical and Gas Safety

The furnace must have an effective electrical ground to prevent the risk of electric shock.

All gas lines must be meticulously checked for leaks before every run. Using inert or reactive gases introduces risks of asphyxiation or chemical reaction if not properly contained.

Pillar 3: Procedural Discipline

A repeatable, step-by-step procedure is essential for minimizing human error.

Before You Begin: Preparation

Perform a pre-operation check. Ensure the furnace tube is clean, dry, and has no visible cracks. Verify that samples have been properly prepared to prevent outgassing that could create unsafe pressure.

Securely install the furnace tube and connect all gas lines, confirming a tight seal at every connection point.

During Operation: Active Monitoring

Never exceed the furnace's rated maximum temperature. This can cause catastrophic failure of the heating elements and insulation.

Continuously monitor the temperature and gas flow rates throughout the experiment. Modern furnaces often have over-temperature protection, but this should be considered a failsafe, not a substitute for vigilance.

After Operation: The Cooldown Protocol

This is a frequently mishandled and dangerous phase. Never force-cool the furnace by opening the chamber. This can crack the furnace tube due to thermal shock.

Allow the furnace to cool naturally to below 100°C before turning off the gas flow or attempting to remove the sample. This prevents both thermal shock and potential oxidation of your sample.

Once the equipment has completely cooled, perform a full shutdown by turning off the power and closing the main valve on the gas cylinder. Finally, clean the furnace tube and work area.

Common Pitfalls to Avoid

Even experienced users can make mistakes. Understanding these common pitfalls is key to building a robust safety culture.

Rushing the Cooldown Process

The desire to access a sample quickly is the most common cause of damaged furnace tubes. The extreme temperature difference between the hot furnace interior and the ambient air creates immense stress, leading to cracks or shattering.

Neglecting Gas System Integrity

A "set it and forget it" attitude towards gas lines is dangerous. Connections can loosen over time. A small, undetected leak of a flammable gas like hydrogen or a toxic gas like ammonia can have severe consequences.

Assuming Safety Features are Infallible

Over-temperature protection and pressure relief valves are backups, not primary control systems. Relying on them to prevent a problem—rather than operating the furnace within its known safe limits—is a sign of poor procedure and invites failure.

Making the Right Choice for Your Goal

Your specific safety focus may change depending on your role and task.

- If your primary focus is establishing a new lab protocol: Document every step, from PPE requirements to shutdown, and mandate hands-on training for all users.

- If your primary focus is routine daily operation: Develop a simple pre-operation checklist and a post-operation cleaning procedure to ensure consistency and equipment longevity.

- If your primary focus is advanced or reactive gas experiments: Pay extreme attention to gas line integrity, material compatibility, and have a clear, tested emergency plan for leaks or reactions.

Ultimately, safety in the lab is an active process, not a passive state.

Summary Table:

| Safety Pillar | Key Measures |

|---|---|

| Personal Readiness | Wear heat-resistant gloves and safety glasses; undergo formal training |

| Laboratory Environment | Ensure proper ventilation; keep area free of flammables; check electrical and gas safety |

| Procedural Discipline | Perform pre-operation checks; monitor temperature and gas flow; follow cooldown protocols |

Ensure your laboratory operates safely and efficiently with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our products can enhance your safety protocols and deliver reliable performance for your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab