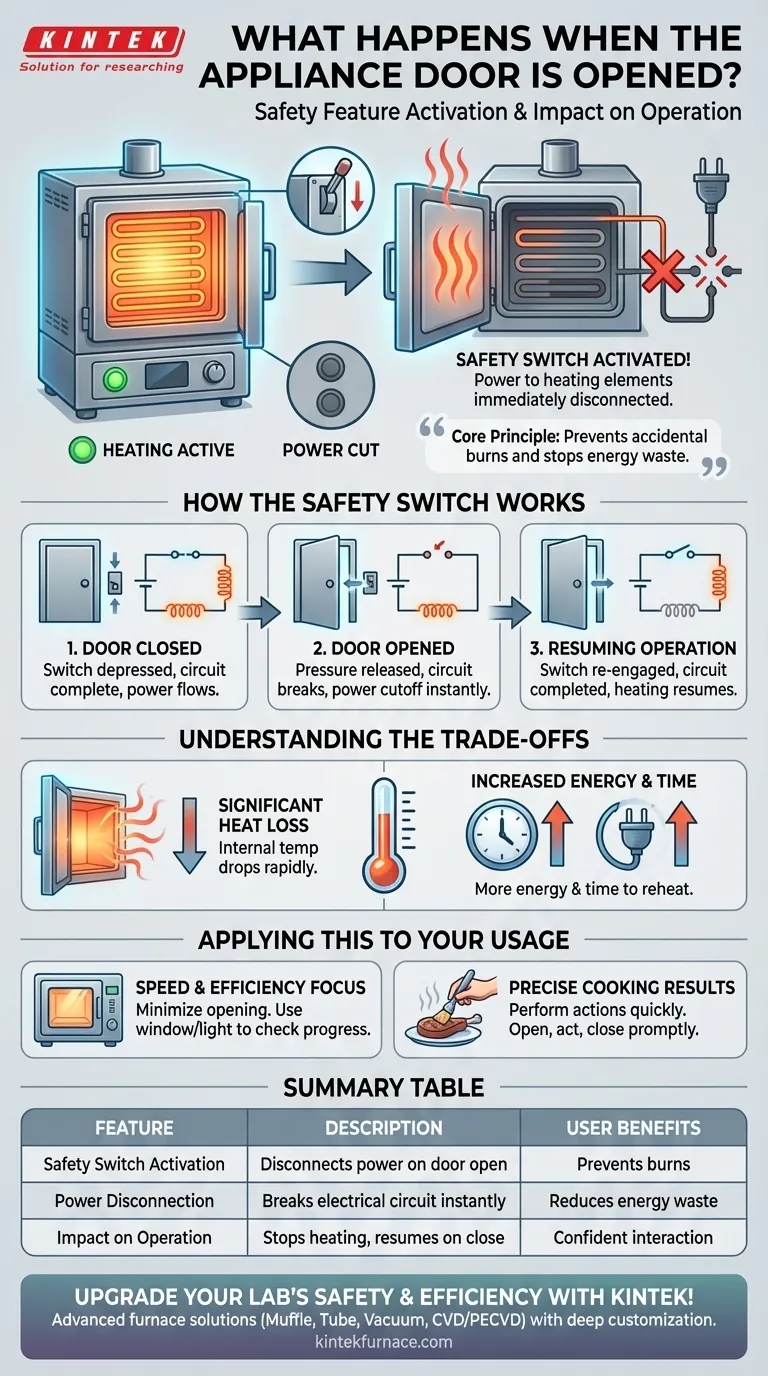

When the appliance door is opened during operation, a safety switch is activated that immediately disconnects power to the heating elements. This is a critical and intentional design feature.

The core principle behind this feature is safety and efficiency. It prevents accidental burns from exposed, active heating elements and stops energy waste by halting the heating process when the cooking chamber is not sealed.

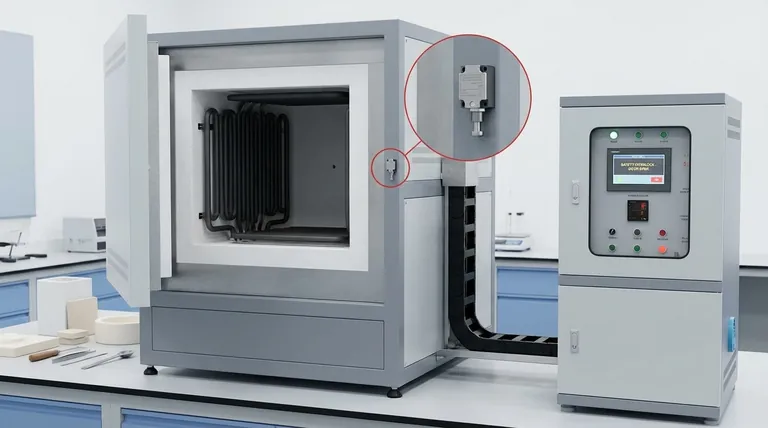

How the Safety Switch Works

The operation of this safety feature is a simple yet effective electromechanical process. It's designed to be fail-safe, protecting both the user and the appliance.

The Role of the Safety Switch

A small safety switch is physically positioned on the appliance's chassis. When the door is fully closed, it depresses this switch, completing an electrical circuit and allowing power to flow to the heating elements.

The Power Disconnection Mechanism

When you open the door, the pressure on the switch is released. This action immediately breaks the electrical circuit.

The result is an instant cutoff of power to the heating elements. This is why you may hear a "click" and see any indicator lights for the heating function turn off.

Resuming Operation

Once the door is closed again, the switch is re-engaged, the circuit is completed, and the heating elements will typically resume operation according to the selected settings.

Understanding the Trade-offs

While this feature is non-negotiable for safety, it's important to understand its effect on the cooking or drying process.

The Impact of Heat Loss

Every time the door is opened, a significant amount of heated air escapes from the chamber. The internal temperature can drop rapidly.

Why This Matters

When the door is closed again, the appliance must expend additional energy and time to bring the internal temperature back up to the set point. Frequent opening and closing can therefore extend cooking times and increase energy consumption.

Applying This to Your Usage

Understanding this mechanism helps you use your appliance more effectively. The goal is to balance the need to check on your food with the need to maintain a stable temperature.

- If your primary focus is speed and efficiency: Minimize how often you open the door. Rely on the appliance's window and internal light to check on progress whenever possible.

- If your primary focus is precise cooking results (e.g., basting): Perform the necessary actions quickly. Open the door, complete your task, and close it promptly to minimize heat loss.

Knowing that the heating elements are safely deactivated empowers you to interact with your appliance confidently.

Summary Table:

| Feature | Description |

|---|---|

| Safety Switch Activation | Disconnects power to heating elements when door opens |

| Power Disconnection | Breaks electrical circuit instantly |

| Impact on Operation | Stops heating, resumes when door closes |

| User Benefits | Prevents burns, reduces energy waste |

Upgrade your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to learn how our products can enhance your operations and protect your team!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production